Hi!

Just bought a used Ender 3 v3 SE and some PLA filament. Never used a 3d printer before. I tried printing 2 things last night and neither worked out. Really fun process / potentials, but not successful first time. Care to read this and offer advice?

Got some STL files, used Creality Print v4.3.7 to open the STL, clicked on normal for the triangles and high quality for the cones. Clicked on slice, local exported the file to the SD.

On the printer, I did a factory reset. Went into leveling in menu. It ran and showed some numbers (some neg, some positive… just informative data, right? Need to do anything with those numbers?)

Then printed the triangles.

After a little while, I see that 1 triangle came off the bed / was on another shape. So I ended that print.

Then on the cones… the 2 cones were separate STLs. I only have 1 color, so I opened both in creality print, clicked on auto for placement on the plate, sliced, saved to SD card.

Started the print and went to bed.

the short cone was off the plate (got pushed off at some point?) and all those little threads were at the top of the ‘finished’ cone. I pulled the little threads off.

With all that, any advice / info?

I saw the extruder got to 205 deg and the plate was 60 deg? (the default temps? I didn’t change those).

I have read about how people wake up and see a blob / 3d printing is not 100% perfect?

Does the fact that I have loads of thin threads mean anything vs. a single blob?

The auto placement wasn’t actually good? How far apart do you place things?

Are the default temps OK? the printer gets that from the slicer file, right? I just said I was using PLA and the extruder is .4

Looking now, there’s all types of settings for the material in creality print! The spool says it’s inland 3d printer filament Silk PLA, 1.75dia, Googling that, I see that the 205 temp is in the middle of the range, 60c plate is at the bottom of 60 - 80c range.

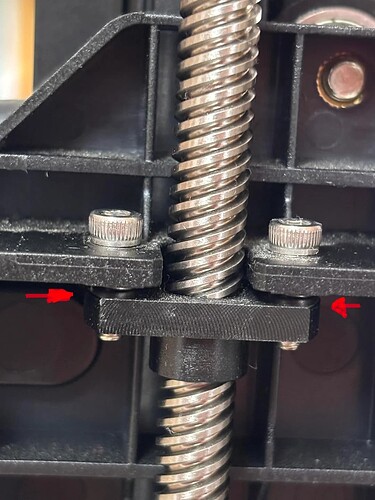

Key question? How tight should all the hex screws be? I tightened some of the screws before printing - a little more snug than they were (most screws kinda felt like they were just touching (as soon as person felt the screw touched the metal, they stopped) / not snugged down. From a video I saw, only the gantry screws are user installed? the ones elsewhere were set by factory (but get loose over time?)

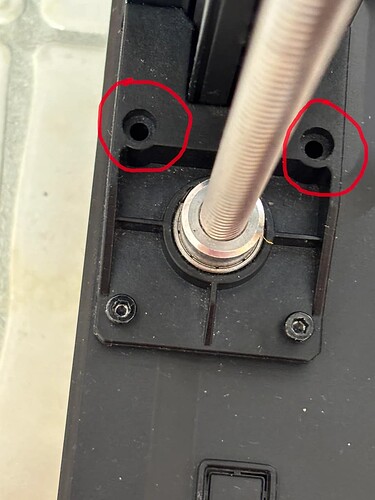

NOTE the gap on the gantry threaded rods. Should there be that gap? How much of a gap?

Is it ok to snug up any and all screws I see?

And I noticed a couple screws that are missing. Any recommendation on where to get replacements?