I recieved my K1C a few days ago and tried to print TPU.

The first few layers work fine but after some time the Filament gets stuck in the extruder. It looks like the extruder gears grind into the Material and the extruder is not able to push the Filament any further. When i pull out the remaining Filament out of the extruder it looks like in the picture i attached.

Hello @KilianB …! ![]()

Welcome to the Creality Forum…! ![]()

I haven’t printed TPU yet but researched that there different types. Some are too soft to push through the extruder so you might look at the different ones to see if they will work…

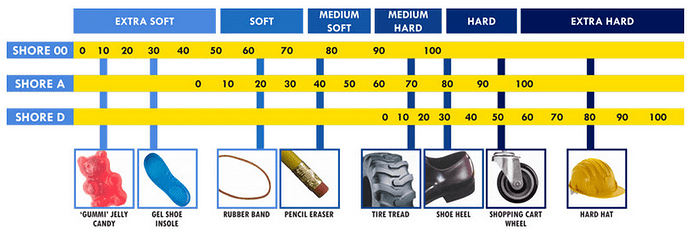

TPU is classified in different shore hardness types for example:

98A is harder than 90A with the number higher as it get harder. The softer one might have trouble printing..

Most of the ones on Amazon are 95A

Thanks for your quick answer.

It is indeed from Amazon and 95A.

Do you have a solution how i can print this Material or di you think i just have to get some harder tpu?

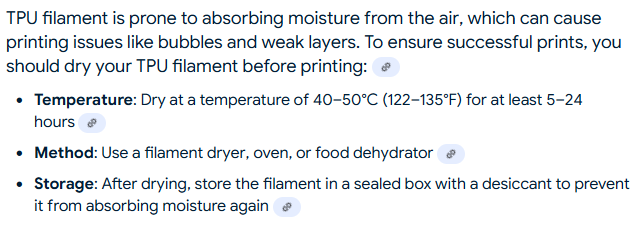

Just like other filaments, TPU needs to be dry to be able to print correctly.

I would do that first and research different temps to see what will work for you.

TPU needs to be printed at quite a slower speed also… ![]()

I’ve not printed it yet and I might learn from you what works… ![]()

TPU especially needs to be dry, it strings all over the place otherwise. Do not print it in an enclosed printers, you’ll get heatcreep and the filament can bind up in the extruder. Remove the lid and open the door of the printer. Being a soft material it is a little like extruding wet spaghetti so keep the retraction distance to about 1mm maximum, there was a maximum number of retractions per distance setting but I can’t find it at the moment. This setting will stop your extruder grinding through the filament. I don’t know if you can adjust the K1 extruder manually, but you don’t want to grip the filament too tight. Some say bypass the bowden tube to give minimum resistance to the filament. I don’t do that. I have my V3SE setup almost exclusively for TPU, probably because it is a quite a slow and non-violent machine so lower your speeds and watch the flowrate. Find a brand you get on with and stick with it, I use Pinuotu but it is hard to find. I’ve used Overture but the flowrate was almost 80% to get a good print. Sunlu TPU I am trying out at the moment, its not bad.

It sticks to PEI like nothing else I have printed. Use gluestick as a release agent not to stick it down. I forgot once, the print took some PEI surface with it, you’d think the TPU would tear, no it is really tough stuff.

I figured it out now.

The spool says to print the tpu at 200 to 230 degrees, but to get it to feed properly i need to heat the nozzle up to 260 degrees. There is some stringing but thats not as big as a Problem.

That is rather high, but if it works thats fine. Had you printed PETG beforehand? Wondering if you had a partial clogged nozzle hence the high temperature.

Yes i have printed petg.

But i made sure the nozzle wasnt clogged. So that shouldnt be the Problem.

Agreed I have swapped between ABS and TPU without a clogging issue. Can’t think why you have to print so high.

Today i tried my first big print with tpu for about 7hrs.

I did a few test prints testing with different temperatures, speeds and retraction settings.

I need min. 250° C to get a good feed.

With this i can print with 100mm/s and with 1mm retraction with 20mm/s and 105% flow i get decent results.

Little stringing but that i can solve with a lighter.

Ich habe das absolut gleiche Problem. Jedoch auch bei höheren Temparaturen (250, 260, 270) das Tpu wird nicht extrahiert, Pla und Petg funktionieren ohne Probleme.

Running a temperature tower in Orca my optimum temperature for TPU is 230°C, 5°C either way and it will string badly. At 250 or above it would be a terrible print, this is using a V3SE which has a different type of extruder perhaps the K1 type extruder doesn’t grip as well as a sprite? PLA and PETG are altogether stiffer so less of an issue?

Habe heute due Lösung via dem Post oben gefunden. Man muss die Kühlung manuell aktivieren. Somit kann ich mit 230 grad drucken. Die kühler müssen auch beim Extrahieren an sein.

Excellent news, now to tune the retraction distance. The default seems to be 0.4mm, this is too little and needs to be closer to 1mm but no higher than 2mm or it might jam in the extruder. The calibration test calibrates for retraction distance and retraction speed.

Hey das sind super news.

Welche Einstellungen nutzt du dann genau?

I was having this same problem with my K1 Max. I tinkered & tinkered with the settings. I FINALLY got it right after I realized that the settings I have were fine, it’s the printer set up that is the problem. My jams were caused by the bowden tube + runout sensor. I printed one of these rigs & switching to that method completely resolved my TPU jamming issue.

I also noticed there has been some discussion about temperature. I did a bunch of test prints with the different temps & found that 250 gave me the best results. Still some stringing but I would call it minor. I am using SainSmart filament.

I have had similar issues with my Creality Hi, at the same point in the print on different occasions it just jams up. I am running it at 250c and I tried to turn off retraction all together.