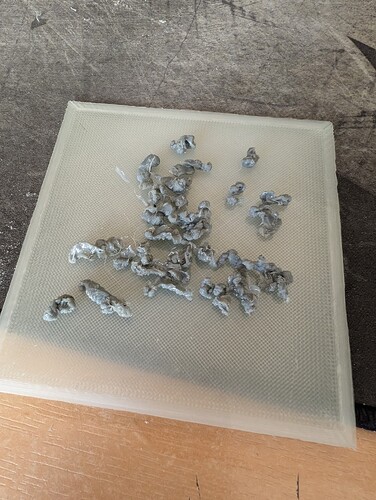

I get this “deposit” when printing PETG. It collects around the nozzle and eventually detaches and drops on to the bed if I’m lucky, or onto the print if I’m not. It doesn’t happen with any other filament.

Is it possible to be over extruding with PETG but not PLA?

1 Like

I think I’ve solved this one…seems to have been a temperature issue. Gone from 235/80 for printing to 240/70 and…zero snot.

3 Likes

Hi can i ask how you are printing with petg, i tried my first petg print today and after 200 hours of pla prints without a single issue it cloged up completely with an extruder error ie nothing coming out at all.

Im using Criality PETG CR-PETG i just selected the stock options in the printer filiment list for this PETG and set it of. I got about half way through the third layer and the stopped.

I had the lid and door closed for this print.

Did you open up the extruder to fix it? What did you see? There are multiple versions of extruder clog. What it is and where it is are the clues to diagnose and prevent it. So for instance was it “dry” shredded filament (I get that a lot with silk filaments) or melted filament? Is it jammed in or wrapped around the gears, or has it just “jumped the track” as it were?

In fact, so many other questions…I know you said you loaded “defaults” - but they change (Creality just released a load of updated ones) so I know it’s a pain but - nozzle temp, bed temp, speed etc. IN fact what printer are you using? I’ve assumed a K2+ just because it’s this forum, but assumptions can make fools of us all…

The K2+ ships with a textured plate, but is set up for smooth - have you changed either?

Closing the door and lid may not have helped. I know you want to prevent draughts to stop curling, but the extra warmth can transmit heat back into the extruder and cause the clog. Try closing the door, but open or remove the lid.

Come back with some answers and we’ll see what we can do.

Oh and this should have been the first question; how old is the PETG and have you dried it?

1 Like

Hi thanks for the reply,

Yes K2 plus

PETG had just arrived from creality but i did not dry it… should I ?

I am up to date on firmware and software so i asume im using the latest profiles.

I have not taken it apart yet as i had to to leave and wont be back until tuesday so its still blocked.

I did remove the nozzel and this came out fine but the CFS could not retract the PETG at this point i had to leave so will take it apart and take photos and post back here as they myboffer some clues.

Thanks for the help.

Petg on the k2 i need a z-offset -0,025 / -0,035 . When the nozzle is to close to the print its getting dirty. there is a sensor for the flow that wil shutdown the extruder motor to protect itself when the pressure getting to high. It also create heatcreep making the petg that coming in to the extruder softer and then you get extruder jams. Petg can best be dryed before printing i dont do it always with new rols mostly i print a little calibration cube or something and then i can see if i need to dry it.

When you dont got a fillament dryer you can set your k2 bed to 50c and the room temp to 50/60c and put the 2 side fans on just to create some airflow petg i dry 4 to 6 hours.

1 Like

Did the PETG warp off the bed and jam/plug the nozzle? One of my PLA prints did that and the nozzle was washboarding over the print until it jammed and errored out. Shredded filament in the extruder, cleaned out and found that in the end the cause was the side fans being turned on by the Creality default setup for Hyper PLA, warped it, I ditched those and cranked the bed up to 60C. No issue since on that cause. My K2 did print CR-PETG out of the bag with stock settings but that may just be luck of the draw. Interesting that it did not retract back into the CFS. Possible cutter issue (anyone?). The upper PTFE tube connector, if not reinforced, is known to shed metal parts and havoc into the hot end in some cases. I have a shroud strain relief on mine, no issues so far there. The hot end tube actually wears a pattern in the film on the underside of the glass top… Not sure if I should take that film off or not.

1 Like

I do have a dryer and i will dry the petg, it was just that i had just opend the sealed bag and thought it would ok to use.

The layers that went down looked perfect. No lifting or anything it just stopped feeding to the nozel.

Hello Anthony_Walker,

The filament that is being wound onto the spools is subject to moisture when being wound and the bag of silica gel that often comes inside that then sealed bag will only draw the moisture trapped in the sealed bag, but it will not remove the moisture present in the filament.

So, it is always best to first dry it before you use it to make sure.

That is what I have found.

Cheers.

1 Like

Thank you i am going to dry it as soon as i get back to work tomorrow as my K2 Plus is in my office atm :).

Thanks to everyone for the advice and sorrg for hijacking this thread.

Just a quick update on my issue.

Firstly thanks for the advice …

Today I very quickly stripped the extruder and i did find a very small blob just above the cutter and removed it and this freed the petg to retract. The cutter had cut the PETG but the vey small blob prevented the retract form happening. What turn out to be the real issue was a blocked nozzel so i replaced the nozzel and have been printing in PETG with Creality settings for over 9 hours today without a single issue.

So all good.

Speaking as the OP, no need to apologise. The thread was so short that without your hijacking it couldn’t have justified its existence!

1 Like