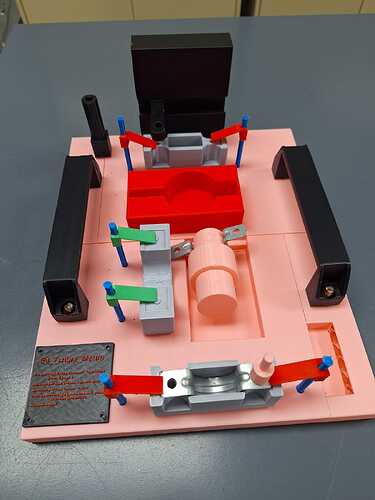

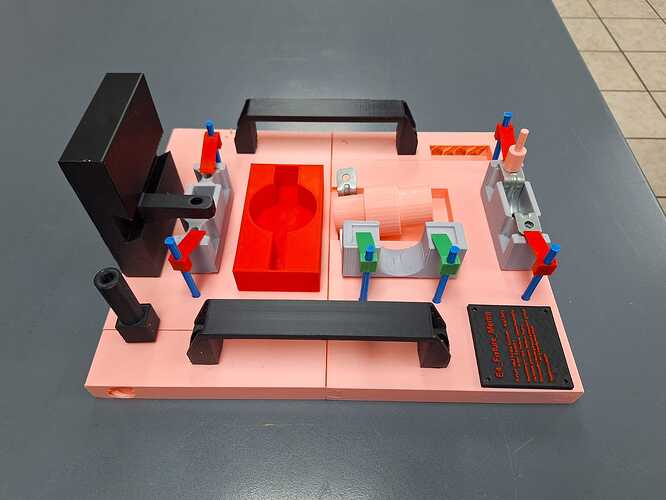

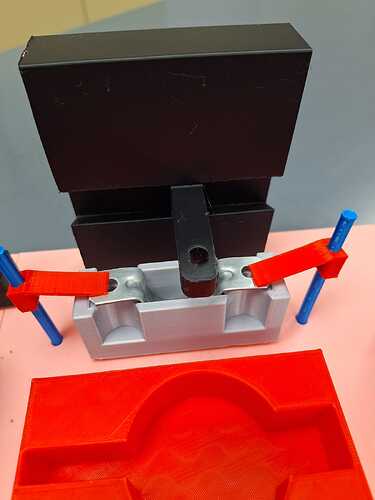

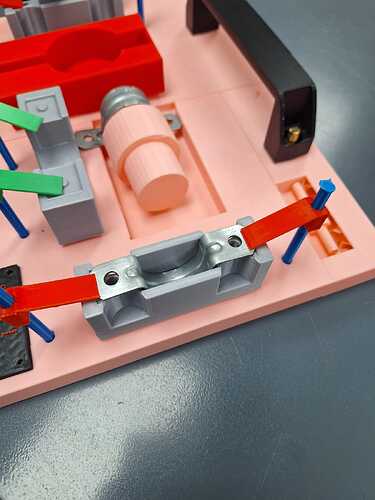

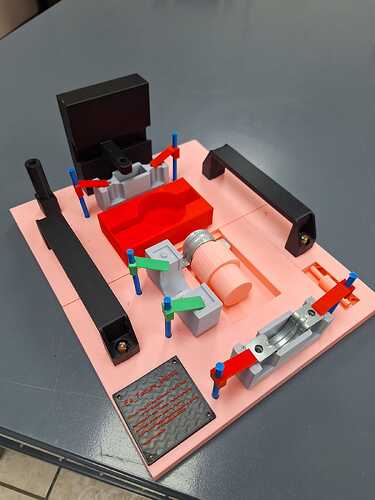

- Model: Omega pipe clamp checking fixture

- Printing Machine: Ender 3 S1 pro and flsun v400

- Selected materials: PLA+ different colors

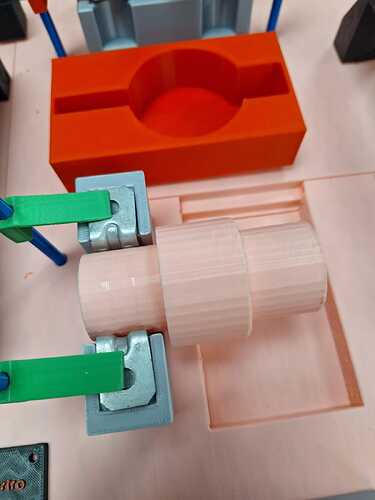

- Print settings: 3 bottom layers, 3 top layers, 2 to 3 side layers, -0.2 mm or -0.15 mm horizontal expansion, 10-5% infill depending on the part, 50% to 100% ventilation, 0.2 mm shrinkage, the base I divided it into 2 parts and assembled it using a dovetail since it did not fit in any printer without dividing it.

- Time spent on printing: Around 3 days

- Description: This is a checking fixture of a clamp from the subject of metrology, during the semester we were learning about some standards and requirements about the manufacturing of parts and how to check that all the parts meet those requirements in terms of measurements. Partially we moved forward, making 3 prototypes and the final model with the aim of making the measurements as fast, precise and comfortable as possible, covering some standards such as ISO 17025 among others, we also used the NX software to model and verify the measurements. ergonomic graphs (the efforts made by the user of the fixture when using it).

- Provide relevant originality proof: Checking fixture abrazadera - Google Drive

- Country/Region: México

1 Like

Now available on creality cloud

Creality Cloud -Omega pipe clamp checking fixture From 4Dsign https://www.crealitycloud.com/model-detail/6685efdab9425ee9fb2c8c8f

1 Like