I noticed my left z-screw always had like 6 teeth left, while the right one only had 2.

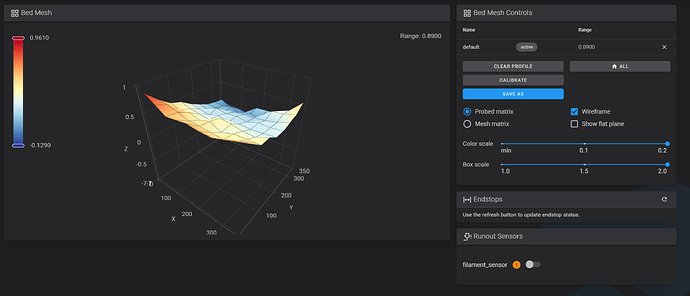

Z_TILT_ADJUST routine will automatically try to align the bed going by the middle left and right points in the mesh - they are configured as 5,175 and 345,175.

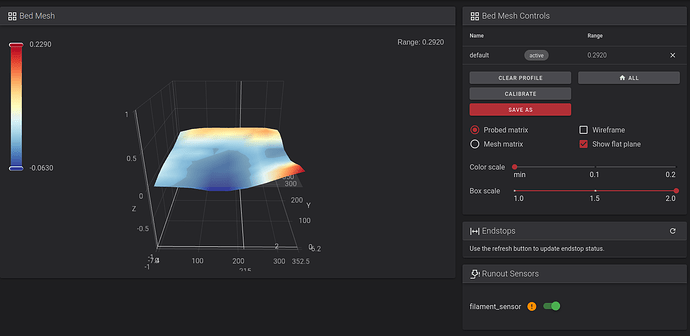

The front right of the bed is higher and the middle right is much lower. There are other points with issues too.

While this doesn’t mean much, it does offer another depth when leveling the bed - you are not forced to ONLY tweak the corner, if you lift the entire left or right side, the other will try to compensate, which got me to get a lower front right.

I did have to compensate slightly with aluminum foil on the right but it got me to something that is temporarily ok; to have consistent prints I would still need to lift several other places in this bed though, as Klipper, weirdly, isn’t being able to compensate.

I have also tweaked some points on printer.cfg to speed up the bed leveling process, have the probe resample some of the data points and, lastly, changed the algorithm factor for calculation of the mesh (some people had success with it, some didn’t)

under [prtouch_v3]

samples_tolerance: 0.01

samples_result: median

samples: 3

under [bed_mesh]

speed: 300

horizontal_move_z: 2

bicubic_tension: 0.5

under [z_tilt]

retry_tolerance: 0.01

klipper, by default, has horizontal_move_z set to 2. Having at at 5 has some benefits, including avoiding a damaged plate if the bed is drasticaly shifted (which can happen with dual Z), but this has been working well for me.

the bed mesh calibration takes 195~ish seconds (slightly faster). There’s also close to another minute for the full routine.

Avoid doing the calibration through fluidd’s interface - the calibration through the printer menu has a few more important steps that must be done before calibrating (including wiping the nozzle and re-leveling the z_tilt).

As a side note, I did have a ticket with support and after being able to talk to an engineer and showing the different pictures of the non-consistent sheets I printed, I will receive a new bed and strain gauge.