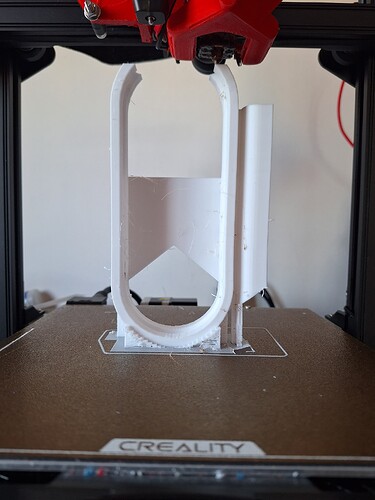

Printing machine: Ender 3 S1 pro and flsun v400

Selected materials: Hiper PLA, PLA+, PETG, ABS

Print Settings: First of all, in some designs where it was very essential to maintain exact measurements, a tolerance of 0.2mm to 0.15mm was taken into account.

Settings for prototypes: 0.2mm layer height, 10% padding, tree supports, and default parameters for all other settings.

Final pieces settings (PETG or ABS): 0.2 mm layer height, 50% infill, 3 side layers, 3 top layers and 3 bottom layers, gyroid infill, tree supports with lower branches from 15 to 40 mm , branch angle of 10°, fan from 50 to 100% in the case of ABS and 30 to 100% in the case of PETG.

Time spent on printing: About 2 weeks between prototypes and final designs

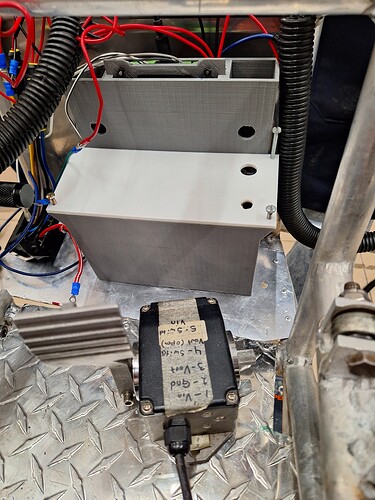

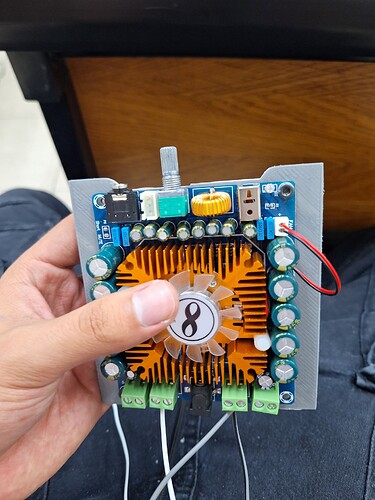

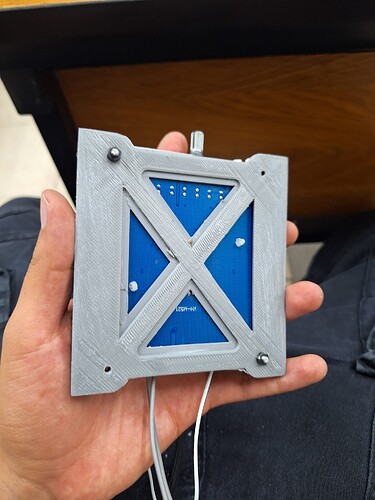

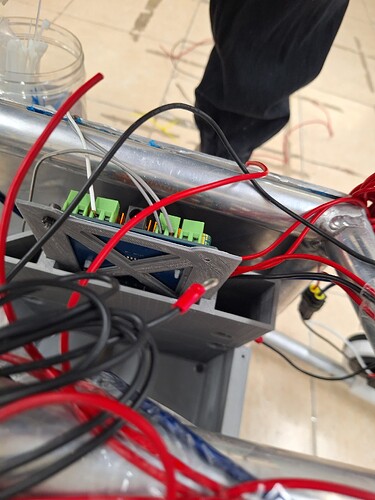

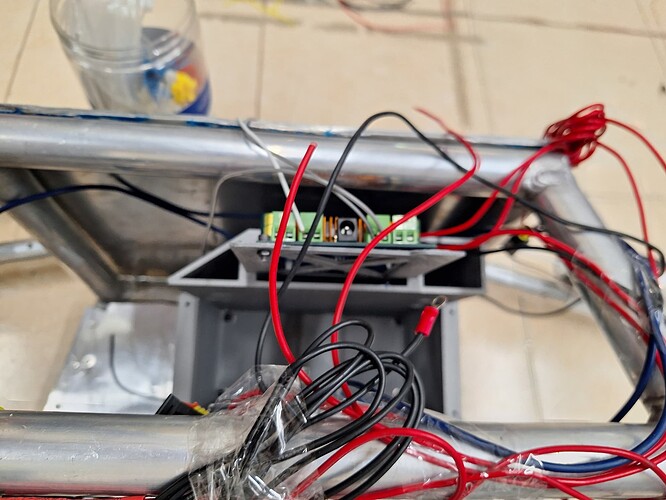

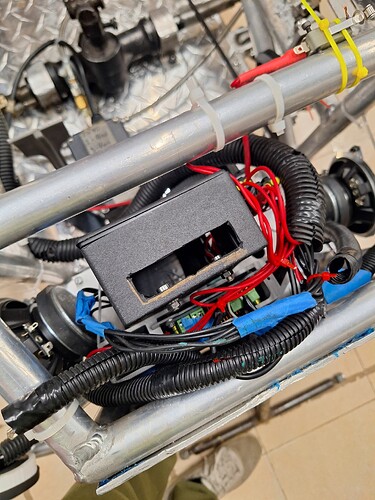

Description: I am part of the Electratón representative team at my university (UPAEP), and I am in the area of telemetry and 3D printing, sometimes there are not many machines available and there we only print parts in ABS, the alternative that I found to be able to print at home It is PLA for the prototypes and PETG for the final parts. We use 3D printing to solve problems in a more precise and planned way, making pieces to the measurements we need for the functions we need. The examples that I present to you below are: 1-bases for brake lights, 2-bases for front lights, 3-box for the telemetry area of the car, 4- radiator support,

Provide relevant proof of originality: I leave you some screenshots and/or videos of the models made in solidworks

Country/Region: Mexico

PS: If you like, you could also support us with printing materials ![]()

We will continue making more 3d printed parts