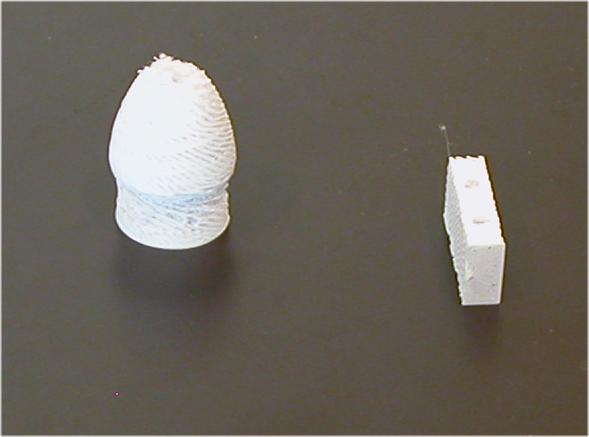

Can someone tell me what I’m doing wrong here? I would expect the finish on this part to be much smoother. It looks like shredded wheat…

How do you upload a picture???

Can someone tell me what I’m doing wrong here? I would expect the finish on this part to be much smoother. It looks like shredded wheat…

How do you upload a picture???

Are you talking about the final layer? It can be improved by turning ironing on, it basically wipes the hot nozzle over the surface to make it smooth.

Is this a setting issue? Software problem? or a hardware (printer) problem?

I would expect to get a better quality outside ‘skin’ than what I’m seeing…

I turned on the ‘ironing’ and there is basically no change.

Looks like it is under extruding, check your esteps and/or flowrate.

I’m using Creality Slicer 4.8.2-291. All of the ‘flow rates’ are set to 100%; I have not touched them. Where is the ‘esteps’ located? I did a search in Slicer using the ‘Search Settings’ and did not find ‘esteps’.

Hardware is Ender3 Pro with latest firmware on Ver 4.2.2 board.

Am I expecting too much from this printer?

Have a read of this if nothing else you will be checking that that setting is correct and can rule that out.

Thanks

I had an initial value of 93 for esteps for the extruder. I did the calibration and ended up with a calculated value of over 300. Does that seem excessive? Could I have a bad extruder stepper or mechanicals? Maybe bad filament?

I’m trying another print to see if I can see any difference. It seems like having to increase the stepper value per mm over 300% seems high.

I also noticed that in some cases, the stepper motor seemed to be turning, but the filament was not really moving… Bad pinch rollers? I think I’m getting closer to the issue.

Thanks again…

Is it the original extruder? 300 and something doesn’t seem too high for a 3:1 ratio extruder, give it a try you can always change it back. My 5 plus has a default rotation distance (similar to esteps) of 33.8 but it should be 7.53 for a direct drive, so it is all based on which extruder you have.

Yes, I believe it is the original extruder. I have ordered a double-gear extruder and will be swapping it out. It bothers me that I can sometimes feel the gear moving, but the filament is not. I’m assuming that it is intermittent on the feed. If the stepper motor is moving, I don’t think that can be the problem. It seems like steppers either work or they don’t.

Can OLD filament do this? Maybe the surface of the filament gets brittle and does not engage with the gear-feeder as well. Just guessing…

Wet filament gets brittle, I run all my printers from a filament drier. Filament that has been in excessive UV is brittle and is scrap. Not enough tension on the extruder it won’t extrude. Worn extruder gears it won’t extrude. Too tight extruder gears and it will wear through the filament during retractions. Lots of variables.

I am very appreciative for your guidance. I have printed another part with the higher eSteps value and I see a much, much better finish. I also see areas where it looks like excessive filament has stuck to the outside skin. This leads me to believe that my extruder is not consistent. I will wait a couple of days for the dual-gear extruder, buy some new filament, and try the calibration again. I think you found it!

I also have a drier. I have dried out most of my filament, then I’ve been storing it in vacuum bags with some desiccant. But I don’t have history on the filament. It came with the printer from a third party. If I buy new, then I know what I have.

Thanks again…

Blobbing and pitting could be wet filament or a little overextrusion, could lower the flowrate a little, but if you don’t know the provenance of the filament I would most likely bin it. Have you fitted a new nozzle? Can’t say I have had a 2nd user machine but you seem to be doing the right upgrades. At least you have managed to get the print to stick to the bed, that is often the hardest part.