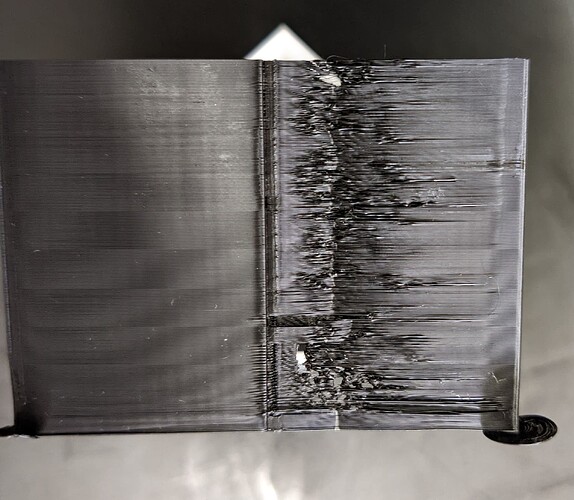

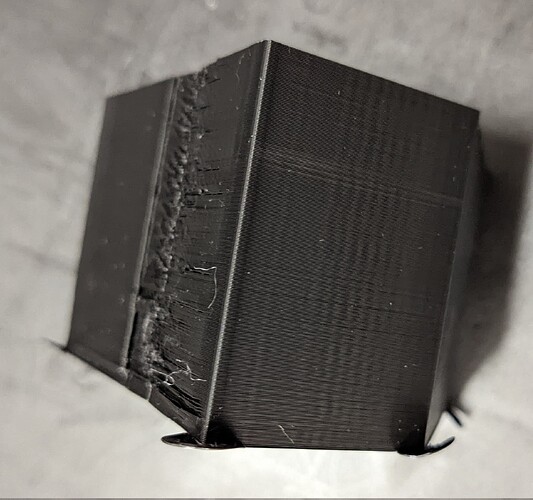

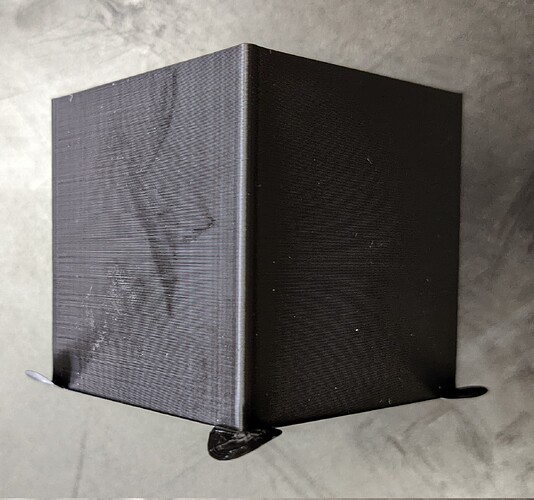

I have a problem with the pressure advance tower with seam calibration printout generated in OrcaSlicer. A section of one wall has a defect. In the middle of this wall the head stops and when moved (after seam) it looks like it is feeding not enough filament. The other walls and the first half of this wall were printed perfectly.

What could be the problem?