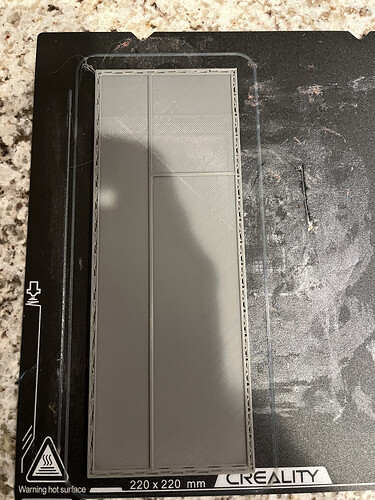

I am trying to print a 190mm x 60mm box. 3mm thick base prints okayed and the first two or three laters of the walls prints okay but then the filament stops sticking to the previous layer. I believe upper left corner is where the failure started. I am using Creality slicer 5.0 recommended settings for PLA. I suspect this issue is because the walls have cooled so much that the filament isn’t sticking to the wall… Will raising the nozzle temperature fix this or will speeding up the print speed fix this.

This has happened twice and the first time the string tangled up in the Y axis tensioner pulley to the point where the pulley stopped turning and the belt broke.

Blue box was first attempt that broke belt. I am 100% certain that the box is not moving on the bed.

I know what’s happening but I don’t know how to fix it: There is a lid that is to be printed next to the box. The printer starts printing the top after it finishes the bottom of the box and does one layer of the walls. The skirt did not stick to the bed, didn’t even try. The bed temp is 60ºC and print temp is 205ºC

FWIW, I print most of my PLA at 220C, and that normally prints just fine. I can’t say I haven’t built a couple of bird’s nests, but that’s usually because I do something wrong. When I print on the textured plate, I typically use a bed temperature of 50C, and no glue. You can try turn the velocity of the part fan down.

BTW, I can’t imagine why you need any kind of brim on a flat object that big! If it ain’t sticking to the build plate, something is seriously wrong.

Try printing first layer thicker (eg .24 instead of ,.2) with an initial bed temp of 70 and no fan for tbe first few layers. If skirt not stick maybe z is too high? You could just get away with mouse ears on the corners of this print to stop them lifting. Rather than a skirt. I add 10 degrees to my printing nozzle temp for going fast with ordinary pla, so esun pla plus at 240 degrees , unless overhangs then 230 degrees. And speeding up the print wont fix your problem, sorry. What kind of filament brand you using…?

Thanks for the responses.

What is not making sense to me is that the bottom 3mm of the box are printing first and printing fine. It’s when the extruder moves next to the already printed box bottom to print the top that the problem occurs. No issues at all printing the bottom, or the whole box by itself for that matter.

I am using Creality PLA

I’ve not had this problem so I’m not speaking from experience, but a couple of things occurred to me. Firstly, test whether the problem lies with the slicer by using another program. Secondly, have you tried reorientating the print on the bed?