Hi there,

I’m experiencing sub-optimal printing quality after replacing the heating element.

A week ago the printer completely stopped working, at first I thought it was due to extrusion issues, but after dismantling and cleaning the extruder, the PLA would flow fine out of just the extruder.

I then feared a clog in the heatsink or nozzle, but I couldn’t remove the nozzle. The nozzle was very stuck (and no more edges after trying to apply pressure, so all wrenches started slipping).

As a solution I ordered a replacement heat-element with nozzle and installed it.

The extrusion started working fine, but experienced poor printing quality.

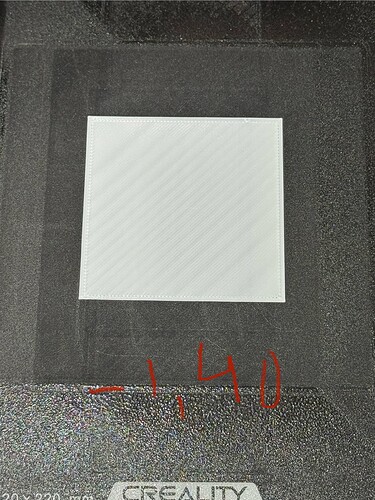

My first assumption was due to nozzle/heat element replacement the automatic Z-calibration wasn’t correct any more. I then did Z-level adjustments directly on the printer, I managed to improve but not resolve the printing issue.

Please see this PDF for all my printing tests:

z-leveling-test.pdf (785.1 KB)

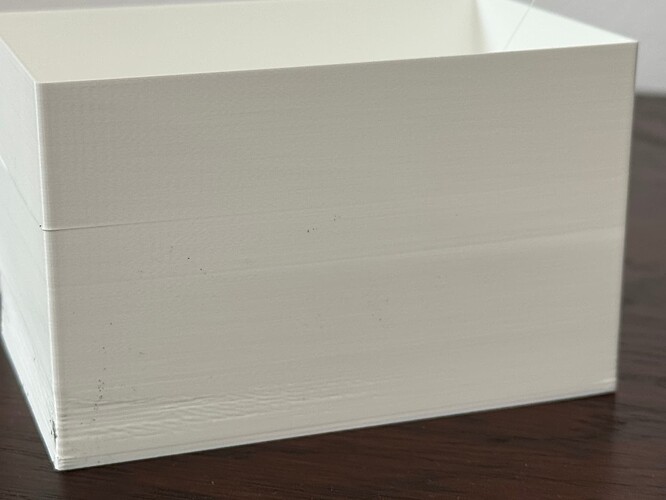

When printing a container, the container walls also do not “stick”, i.e. each horizontal line does not remain connected and the box breaks.

This is printing with a Gcode and PLA-product that would previously give me great printing results, meaning it cannot be printing speed or temperature.

Can you provide any further advise on what I can try?

Please see attached PDF file with my Z-leveling tests, the best result is -1.40, any lower or higher is less good. But -1,40 is not good enough.

Please advise!

KR,

Rik