Been a while because I working on the K1. Now it has a diamondback nozzle and a cartographer now, but feeling the slowness. I want to update the MCU to a m5p unit but need to research that more.

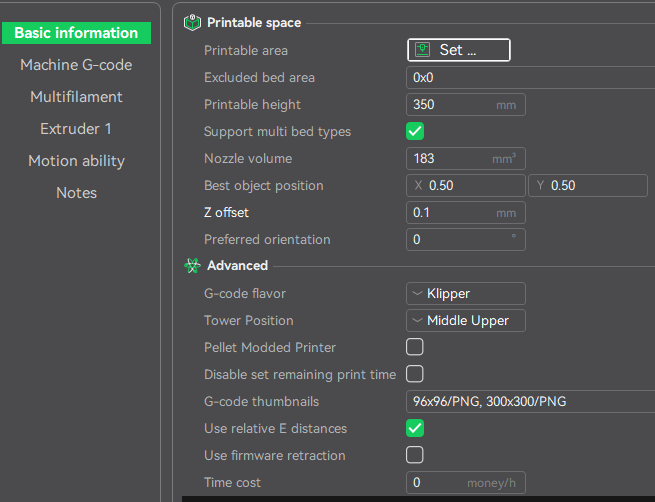

Now for this issue, as @Anubis132 has mentioned the Z-Offset is not being set which leads to issues with the first layer printing. After doing a cursory review of the gcode_macro.cfg this code stood out. especially after looking at the shared links where frankjoke had posted some code about Z-Offset.

[gcode_macro G28] gcode: ACCURATE_HOME_Z SET_GCODE_OFFSET Z={printer.toolhead.z_offset|default(0.0)}

Now to my understanding to this is that G28 correctly homes the printer, but SET_GCODE_OFFSET Z=0.0 wipes out any stored offset. If your Z offset was tuned for perfect first-layer adhesion, this macro removes it. If you use G29 (automatic bed leveling), Klipper calculates adjustments for an uneven bed. But since G28 resets the Z offset, the printer ignores the leveling data.

Here is a sample code with a sligtly modified code.

Preformatted text [gcode_macro G28] gcode: ACCURATE_HOME_Z SET_GCODE_OFFSET Z={printer.toolhead.z_offset|default(-0.1)}

Where {printer.toolhead.z_offset|default(0.0)} is now {printer.toolhead.z_offset|default(-0.1)} represents a manual entry for the Z-Offset.

Why Use -0.1 for Z Offset? Can It Be Any Measured Value?

** What Does SET_GCODE_OFFSET Z=-0.1 Do?**

The SET_GCODE_OFFSET command adjusts the Z position of the nozzle relative to the homed position.

- A negative value (-0.1mm) moves the nozzle closer to the bed.

- A positive value (+0.1mm) moves the nozzle farther away from the bed.

This is useful for fine-tuning the first layer height to improve adhesion and print quality.

** Why -0.1 Specifically?**

The value -0.1mm is just an example.

It is not a fixed number and should be adjusted based on your printer’s needs.

The Correct Z Offset Depends On:

-

Your Printer’s Mechanical Accuracy

- Each printer has a slightly different Z height after homing.

- Some machines may need

-0.05mm, while others may need -0.2mm.

-

Bed Leveling and Surface Type

- If your bed is slightly higher than expected, you may need a smaller Z offset (e.g.,

-0.05mm).

- If using a thick build surface (like glass), you may need a larger Z offset (e.g.,

-0.3mm).

-

Your First-Layer Calibration

- A well-tuned first layer sticks well to the bed without being too squished or too high.

** How to Find Your Correct Z Offset**

Since -0.1mm is just a starting point, follow these steps to find your ideal offset:

** Manually Home the Printer**

Run this command to home the Z-axis:

G28 Z

This moves the nozzle to the printer’s default zero position.

** Move the Nozzle Down in Small Steps**

Move the nozzle closer to the bed using the following command:

G1 Z0.2 F300

Then keep moving down in 0.05mm steps:

G1 Z0.15

G1 Z0.1

G1 Z0.05

- Stop when the nozzle barely touches a piece of paper (common test method).

- You should feel slight resistance when sliding the paper under the nozzle.

** Set and Save the Offset**

Once you’ve found the ideal height, use:

SET_GCODE_OFFSET Z=-0.15

SAVE_CONFIG

(Replace -0.15 with your measured value)

** Test with a First-Layer Print**

Start a small test print and observe:

- If the nozzle is too high (poor adhesion), increase the negative offset (

Z=-0.2).

- If the nozzle is too low (scraping the bed), decrease the negative offset (

Z=-0.05).

The next thing that stands out is the bed mesh. I looked at that section because I felt like the mesh was not being loaded. And here is what that macro looks like:

G28

G29

From here, the firmware does a G29 command and performs a be leveling procedure. However, if there is a mesh it does not load it. A possible fix is

G28 Z ; Home only Z

BED_MESH_PROFILE LOAD=default

G29

** What is Happening?**

In the original Klipper firmware, the START_PRINT macro calls G28 (homing) and G29 (bed leveling), but does not load the previously saved bed mesh.

Original Code

G28 ; Home all axes

G29 ; Run bed leveling

What this does:

G28 homes the printer → Moves the nozzle to a reference position.G29 runs bed leveling → Probes the bed to generate a height compensation map.- However, if a bed mesh already exists, it is not loaded, meaning Klipper ignores previous leveling data.

** Why Is This a Problem?**

-

Bed leveling (G29) takes time

- Every time a print starts, the printer re-probes the bed, even if the last mesh is accurate.

- This wastes time when a saved mesh could be used instead.

-

The printer doesn’t compensate for an uneven bed

- If the printer restarts, Klipper doesn’t automatically load the last mesh.

- This can cause first-layer adhesion issues, as the nozzle doesn’t adjust for bed inconsistencies.

-

If a new mesh isn’t generated, the printer might use no compensation

- Without loading a saved mesh, the printer might print as if the bed is completely flat (which it usually isn’t).

** Correcting the Issue**

Instead of running G29 every time, we should first load the last saved mesh.

** Fixed Code**

G28 Z ; Home only Z

BED_MESH_PROFILE LOAD=default

G29

** How This Fix Works**

G28 Z → Homes only the Z-axis, reducing unnecessary XY movement.BED_MESH_PROFILE LOAD=default → Loads the last saved mesh before running G29.G29 → Runs a new bed leveling only if needed.

I have not tested this theory but I am just looking through the firmware to see what is going on at the moment. the next area I want to look at is the heating issue taht was mentioned. Also, I am not an expert nor do I claim to be I am mostly posted what I see as possible issues and looking for confirmations or different opinions. These code section can be found in the gcode_macro.cfg under the [gcode_macro START_PRINT]