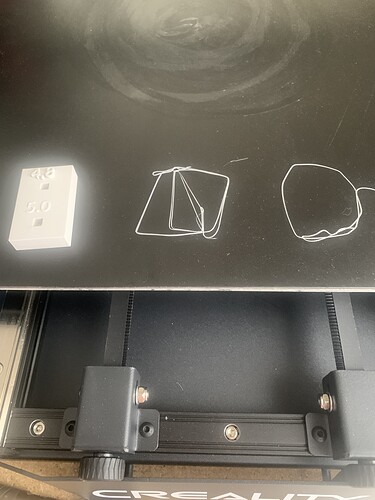

My CR M4 printer is at -145 Z offset and the PLA filament is not adhering to the build plate. The object is too large compared to what is on file. The corners are rounded not rectangular 90 degrees. The PLA is to loose and when the nozzle goes over the print it gathers the material. What do I do?

Z offset is too high. You should be able to adjust it on the fly. I would print a skirt of 3-5 wide before the actual print to get that Z offset adjusted perfectly. I have to do it on all 4 of my printers, it’s a simple adjust of lowering the Z offset by 0.05mm increments until it squishes into the bed properly.

I tried a -50 Z offset however even that doesn’t work.

Can you get the nozzle down to the thickness of a piece of paper? Then drop the Z down by another 0.05mm and you should be pretty close.

I have dropped the nozzle down to -155 z-offset. I used some SIBOOR PVP glu stick. I washed the PEI sheet and used isopropyl alcohol on it. I built the print using a raft. The model adhered but after a few hours it slid off the build sheet and landed on the floor. I cannot finish a print on the CRM4. Nothing stays fixed on the PEI sheet. I am using PLA. Do I need a textured PEI sheet?

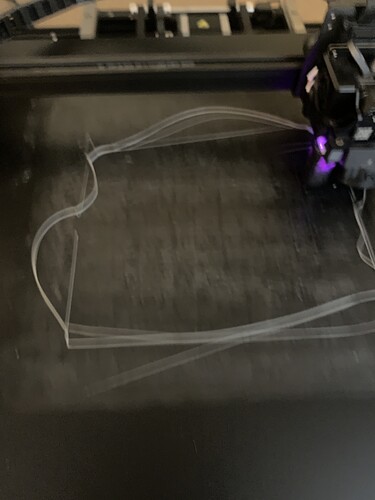

I cannot use a brim because when I print a brim the CRM4 only prints an outline and then the brim fails. Here is an attached photo of what happens when I attempt a brim.