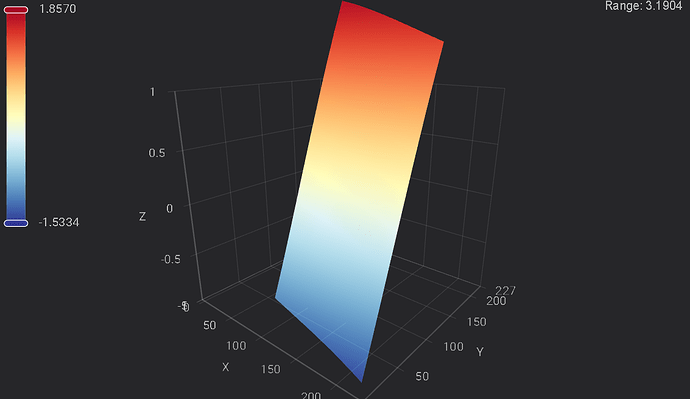

Hi. I recently purchased a Creality K1 SE printer. My last printer was a Ender 3 Neo. I purchased that in Feb this year and within two weeks of purchasing It was having problems. Obviously, it was under warranty and started talking to Creality Tech Support and CS. They sent me a couple of replacement parts but unfortunately that made no difference. The printer is now 5 months old from new and is chucked in the corner of the garage gathering dust. I would hate to think how many phone calls, emails etc , I have sent and after 5 months of Creality asking for test after test after test, and getting nowhere I gave up trying any longer and purchased the K1 SE printer a couple of weeks ago. As soon as I set it up, I noticed a problem more or less immediately. If I print a test item, lets say 1mm thick (just a figure, it doesn’t really matter) and a length which is very close to the maximum length in the y axis, as it prints from say a Y 10mm position to a Y 200mm position straight from front to back on the plate, the plate actually rises and falls in the z axis by in excess of 5mm. I have tried most things, right from the obvious checks to a complete factory reset and let it run through the self checks again. Creality have told me it “could” be a problem with either the bed or the 4 pressure pads underneath the bed. They have sent replacements for both those parts which I should receive on August 4th (Next Monday). I’m getting a sneaking suspicion that this is not going to make any difference. Lets hope I am proved wrong and pleasantly surprised. Has anyone come across this before? When I get the mesh report up after the self checks the mesh is actually vertical and completely off the scale, almost a full 90 degrees to where you would expect it to be. I think CReality were quite shocked when I sent it to them. If anyone out there has any idea what it could be, it would be greatly appreciated. Regards Geoff.

P.S. The only reason I purchased another Creality printer after the brand new Neo gave up the ghost, plus Creality Customer Service performing in a way they are notorious for, is that I have been using Creality printers for many years and pretty much know them inside out so I have given them one more chance. I actually have two Creality printers now, both still under warranty and are thick with dust in the garage. One was two weeks old from new, the other was around 5 months old from new. I got so peeved off with them, I couldn’t even be bothered to cover them up so very soon there will be two nearly new Creality printers going to the rubbish tip. Heartbreaking I know, but i am so frustrated and annoyed with Creality, I just can’t be bothered wasting any more of my time with them. If I don’t get this resolved, then i’ll unfortunately have to look at other printers. Plus, obviously, I also can’t afford to keep throwing 100’s of £££ down the toilet. I apologise. Rant over, but if anyone has any good ideas as to why the bed should be so far out, they would be greatly received. To finish, If i look side on at the printer I can immediately see the bed is not level in relation to the frame or print head without the need for running tests. Ouch.

Can you upload a pic of your bed mesh ?

Hi Steve. Sorry for the delay. Please find the bed mesh for the printer. Done a few things to no avail. Just done a full factory reset but no different. Spoken with Creality and (for what its worth), Their thoughts were it could be the Strain Gauges and Motherboard they plug into, so sent me some of those which I have fitted with no success whatsoever, which is what I thought would be the outcome.

I’ve been a bit crude to try and get it better. I have some engineering measuring blocks which are certified to be withing .001mm in their accuracy. I stuck one of those under each corner of the bed and literally sent a g code to drop the bed onto the blocks forcing the bed down flat onto the blocks and with a lot of teeth jumping over cogs etc, its better than it was, although I would like it to be much better. I am sure there must be a much better way of doing it, rather than my Heath Robinson attempt,

Cheers

Geoff

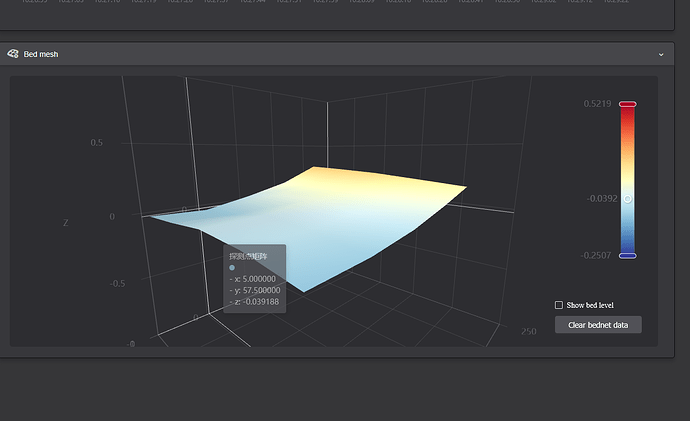

That definitely looks like faulty load sensors. Mine had a problem where the front of the bed was around 1.6mm lower then the back.

I printed some tiny 1.6mm washers and inserted them at the front where the four allen screws secure the bed to the front risers between the two metal parts and the bed is now much better. The whole thing is only out by around 0.2mm now.

What makes me think that yours is a sensor fault is that the mesh image looks dead smooth, there is no variation at all between the 25 probe points.

To be honest, if you havent had it long, and purchased it new i would probably demand a replacement if the bed really is that bad