I’ve had the K1 for a year now. 3 months ago I had to change the extruder circuit board and that’s how I installed the successor model of the extruder.

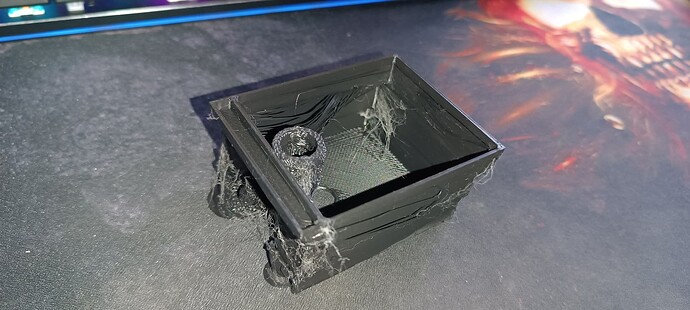

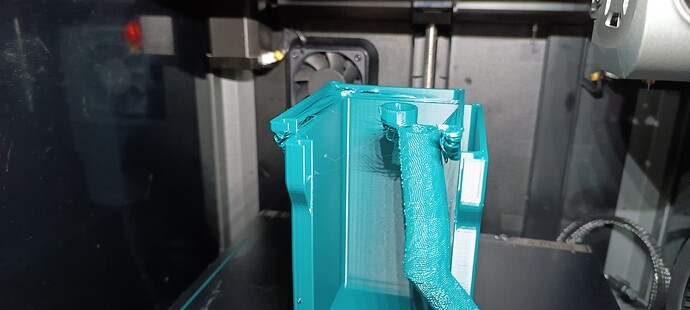

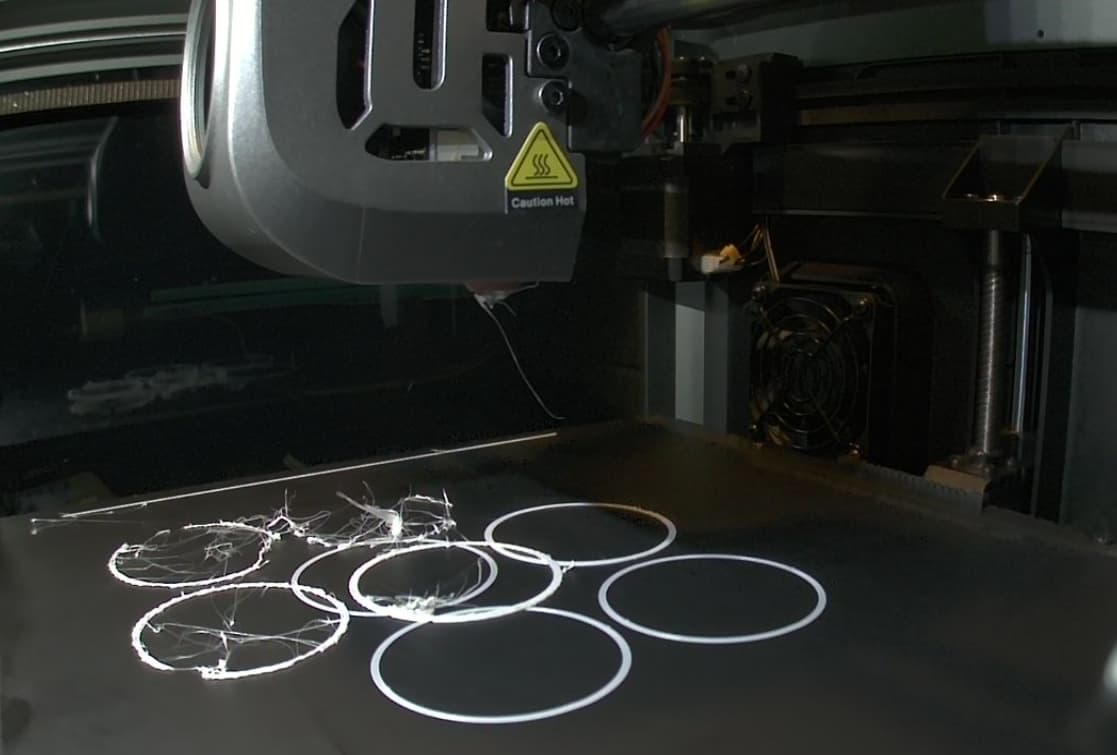

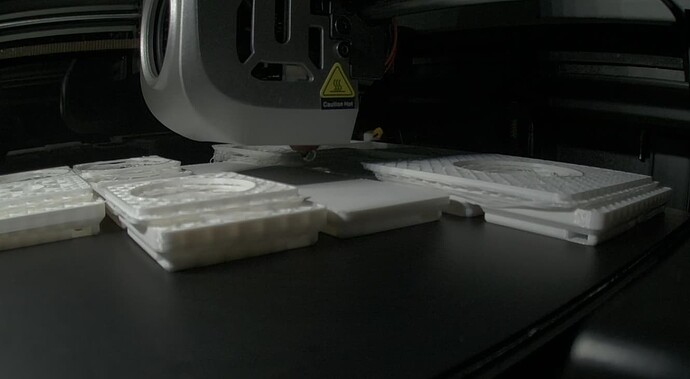

Everything was working great until 2 weeks ago. Suddenly I have shifts in the layers in the middle of printing. Is this perhaps a defect?

If I had changed something I wouldn’t be surprised.

I tried this with different filaments. Always the same result.

Any tips? Or does the K1 only last for 1 year and is then so worn out that it causes such errors?

Did you ever find out the cause of shifting layers? My new K1C (late Dec. 2024) did this initially on large perimeter jobs. Now, almost every job fails. I hear what sounds like a belt slip, then the print continues offset. I have to STOP the print. The error log shows Warning key:2001,Unknown exception.

Hey, I have exactly the same issue… All belts are fine, bed is fine, everything is as it should be. I even changed to using OrcaSlicer and it was OK for a print or 2 and then reverted back to this (as your pic displays). Lets hope we hear something from someone. I’ve been looking at all sorts of blogs etc but nothing seems to work. … In hindsight perhaps I should have gone for the Bambu Labs P1S…

I had to get very assertive on what I referred to as an ultimatum. I contacted my bank’s credit card and they suggested I escalate to PayPal. Once I confronted their Chinese support and my Canadian sales office, they finally conceded. They promised me a replacement device. They tried everything to wiggle out; recommending advanced changes to Creality Print 6, asked for video proof and other nonsense requests. You may have to jump through their hoops but stick to your guns. As we say in Canada “bonne chance”.

Here’s my current status.

After my ultimatum, they agreed to send a new motherboard and both X and Y motors. So, rather than fix their problem, they send token parts in the hope we have the technical ability and desire to repair their responsibilities. It’s somewhat like certain car companies who refuse to honour their warranty until the car has gotten out of warranty.

Thankfully I received the motherboard from their Texas office to Canada just before the tariffs were imposed! The X and Y motors are on their way from Hong Kong. I’ll wait until the motors arrive to attempt a repair; putting the monkey on my back to fix their problem. This sure is not an optimal way to provide customer service!

The old motherboard connectors are impossible to remove due to epoxy inside all 13 connectors. The two axis drive motors arrived yesterday but their own video on the replacement procedure is ridiculously difficult if not impossible. I have issued them a repeat of my last conditions and caveats; otherwise I will be submitting my refund claim to PayPal. Stay tuned,

I’m having this issue too all of a sudden on my K1C. The printer was fine with all types and sizes of prints. Then just a few days ago I started having this problem. Somewhere mid-print it’s like the whole layout gets shifted 10mm to one side (or maybe it rotated?). The other day it was the first layer and this time I was about 3/4 of the way through a 4 hour print when all of a sudden things untethered. The first time happened with a print from Orca Slicer, beta 2 I think, and this time I started the print from 6.0.4.1794. I guess I’m not clear how much if at all Creality Print trails Orca Slicer.

Seeking solutions. Thanks to anyone who might be able to help

Sorry to hear but somewhat glad i’m not the only one with this identical deficiency. Creality admits they have no facility in at least North America to fix this problem, so while under warranty they will throw parts at you; hoping you have the skills and patience to do your own repair.

I’ll bet a Canadian dollar they will ask you to provide pictures, your GCODE file and a video only after forcing you to make configuration changes to their Creality Print 6 slicer! Been there; done that!

I further discovered the “glue” used for motherboard connectors is in fact hot gun glue that is impossible to remove. On one of their Wiki postings, they admit that a loose connector may cause a component failure on the motherboard.

I’ll give their Chinese office another day to REPAIR, REPLACE, or REFUND otherwise PayPal is my only option. As we say in Canada “bonne chance”.

Issue Resolved: Since REPAIR or REPLACE were not to my liking, Creality finally conceded and did a REFUND, only after I repackaged the K1C with the repair parts they sent. They did pay for the shipment and once received, I did get most of my money back, less the PayPal fee.

Me too, started yesterday. 40-60 layers into a big (200x190mm) print, a loud CRACK and a layer shift of at least an inch in both X and Y. This doesn’t seem like a belt hop, it wouldn’t hop that many steps. Tried Creality Print 5, 6, and Orca, same thing. Rotated the print, same thing. If this isn’t fixable, it’s going back.

I had to force them to provide a refund after I contacted PayPal. PayPal required me to documented my entire ordeal and I guess that’s what actioned my refund from Creality. There is something seriously wrong with the Creality K1C and it can only get worse. Even small jobs (i.e. Benchy) will fail. I used my refund to purchase an Ender 3 V3 KE and it’s spectacular. The print speed is 500 mm/s, extruder heats to 300℃ and can communicate with the WiFi Creality Cloud, through Creality Print 6. I have re-printed all of the jobs that failed on my K1C and not only do they flawlessly print, the quality seems to be better. Best of all, the Ender 3 V3 KE is about 1/2 the price of the K1C.

Sorry: extruder

I doubt the bed can get to 300C, likely not over 100C

Jeremy: Thanks for pointing out my typo. I let the slicer set the recommended values for the model and type of filament. I’ve never needed to override the defaults.

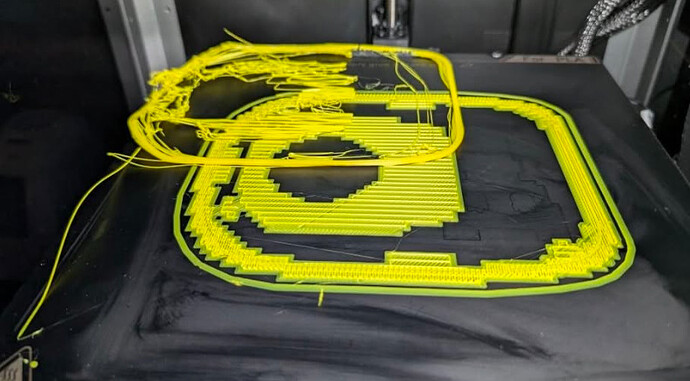

I finally got back to this over the weekend. It likely was the belt tension, I followed the tensioning procedure tuning both belts for 110-120 hz tones in the Gates app and now it is back to printing accurately, even on 8-10 hour prints.

This is exactly what needs to be done. Ive had this issue with the K1 since day 1. Creality needs to step up and support their products or stop producing this crap. Enough is enough

i had this issue i posted in another section, but it turned out my k1c was over heating becasue the bottom plate was poorly made and no exit vents for the air to flow through, my temp after i found the layer shift and stopped it was around 56c, i removed the feet and plate, and on another printer i made feet extensions and a fan mount for the mcu, i reran my print on my K1C a 7h 23m part keep checking the temp of the bottom area and came out just fine, before i had done this it had a layer shift before so this is what happend to me i hope this might be helpful to anyone with this issue i had and FYI im making my own bottom plate… with proper air vents…