5.Case Study on the Application of Flexible Filaments - Shoes

5.1.Selection of Printers

Based on the previous chapters, our company will provide a tailor-made extruder as an accessory for printing with flexible flaments, which can be retroftted according to the user’s existing machine. The provided extruder is modifed based on the sprite extruder, and the electrical system and materials are interchangeable. Based on this, the following factors should be considered when selecting a machine:

1)firstly, choose a machine with stable performance, strong transformability, and with many retroftting tutorials, such as Ender3, and Ender3V2.

Secondly, consider the models that are equipped with the sprite extruder and retrofttable by replacing the sprite extruder and changing relevant parameters of the extruder, and are easy for parts replacement, such as Ender3 S1/S1 Pro, CR-10 Smart Pro.

5.2.Selection of Material

When using the Fused deposition modeling process to print shoes, material selection should consider such factors as wear resistance, elasticity, impact resistance, and lightweight.

5.2.1.Selection of Material Type

Based on the analysis of material properties and applications in Chapter 2, the following can be concluded:

1)TPC and TPA are not suitable for printing shoes with Fused deposition modeling process due to their relatively poor elasticity.

2)TPE is more diffcult to print compared to TPU and TPR.

3)In terms of price, TPC and TPA are relatively expensive, followed by TPE and TPU, while TPR is the cheapest.

further analysis shows that:

TPR, TPE, and TPU are suitable materials for shoe printing with Fused deposition modeling process. If considering cost and ease of use, TPR is the preferred material for printing shoes with Fused deposition modeling process. However, it is necessary to increase the strength and tear resistance of the printed parts through post-processing such as chemical treatment because TPR has weaker interlayer adhesion ability compared to TPU.

Considering wear resistance and durability, TPU and TPE can be chosen as materials for 3D printing of shoes using Fused deposition modeling process, and supports can be reduced in the design of shoe model.

5.2.2.Selection of Material Hardness

The selection of material hardness mainly involves the consideration of softness, elasticity, and printing diffculty of the material.

TPR material has a Shore Hardness of 0A - 100A, while TPU material has a Shore Hardness of 60A - 55D. The higher the hardness, the harder the material and the worse the flexibility, but the lower the printing diffculty. Comparison reveals that TPU85A or materials of higher rating are too hard for printing shoes. TPU80A is not flexible enough and has certain degree of printing diffculty. TPU65A is very flexible, but it’s too diffcult to print.

TPR65A and TPU70A are suitable for printing shoes. TPR65A is prioritized as it is comparatively more readily available.

5.2.3.Selection of Filament Diameter

The selection of flament diameter is mainly based on the diffculty of flament manufacturing and printing.

Currently, flaments with a hardness below 80A are too soft, and if a 1.75 mm diameter is used, the manufacturing of the flament will be very diffcult, which greatly increases the requirements for the printer.

Therefore, a flament diameter of 2.85 mm is selected for TPR65A.

5.3.Slicing

Basic conditions: TPR65A flament, with a diameter of 2.85 mm; direct-drive sprite extruder nozzle diameter of 0.8 mm.

Based on the above conditions, the slicing parameters are set for model slicing.

5.3.1.Placement of the Model

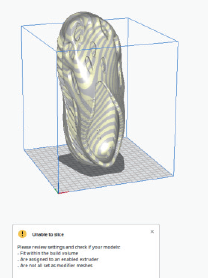

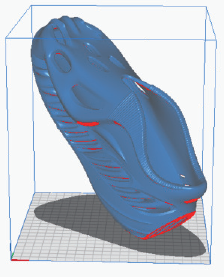

After importing the model into the slicing software, the placement of the model shall be considered frst based on the principle of minimal support. It is preferable to place the model with the heel down and the toe up.

- Maximum size of shoe model ≤ Z direction of printing device

Select a single shoe model, import it into the slicing software, and place it with the heel facing downwards, as shown below.

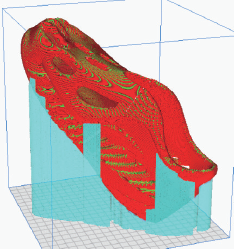

2)The maximum size of the shoe model > the maximum size in the Z-direction of the printing device Select a singular shoe model and import it into the slicing software. Whether oriented vertically or horizontally, the model will exceed the boundaries and change in color, making it un-sliceable by the software, as shown in figure 5.3-2. It is necessary to rotate the model by a certain angle along the X-axis and then by a certain angle along the Z-axis to ft the printing size of the device, as shown in figure 5.3-3.

5.3.2.Settings of Layer Height and Line Width

The main parameters suitable for printing the model are confrmed through slicing. The basic premise of the slicing is as follows:

Slicing software Cura5.2.1, improved sprite extruder, with a nozzle diameter of 0.8 mm and TPR65A flament with a diameter of 2.85 mm.

When selecting layer height, printing effciency is the frst consideration, followed by achieving the best possible print quality. Layer height is usually selected as a multiple of nozzle diameter, ranging from 0.2 to 0.8 times. During printing, the nozzle flow rate equals the printing speed times the layer height times the line width. The larger the flow rate, the shorter the printing time. The printing speed of flexible flament should not be too fast, thus optimizing layer height and line width is the only option. If the layer height is set too small, printing time will be too long.

The printing quality is divided into three levels: rough, normal, and fne, with layer heights of 0.48 mm, 0.4 mm, and 0.32 mm respectively, corresponding to 60%, 50%, and 40% of the nozzle diameter. The commonly used layer height setting is 0.4 mm.

5.3.3.Settings of Top and Bottom Layers, and Shell

This design primarily involves using flexible flament for shoe printing. In light of the durability of the shoe and the moderate wear resistance of TPR65A, we aim to increase the thickness of the shoe sole to minimize wear and tear. However, an overly thick sole can lead to reduced flexibility. After comprehensive consideration, the slicing thickness of bottom layer is set to 2mm, which means 5 layers. The top layer is also divided into 5 layers.

5.3.4.Infll Setting

for the infll, flling type and infll density are main factors to consider.

Shoes primarily bear forces from the human body and will experience certain forces in the X, Y, and Z directions. Therefore, 3D infll should be chosen. The suitable inflls include cube, tetrahedron, and spiral twenty-four-sided polyhedron. Cube is the preferred choice.

If the infll density is too high, the shoe will become hard, and the elasticity and comfort will decrease. If the infll density is too low, the strength is not enough. It is recommended to set the flling density to 20%.

5.3.5.Temperature Setting

The material setting mainly takes into account the temperature and flow rate related to the material. As described in Chapter 3.2, the optimal temperature is confrmed through temperature tower testing. Result analysis Result analysis mainly considers three aspects: degree of stringing, interlayer adhesion ability, and surface roughness.

Stringing: By analyzing the printed temperature tower, it was found that stringing is minimized when the temperature is set to 215℃ and 220℃.

(2)Interlayer adhesion: Insuffcient extrusion and cracking between layers occur at 200℃ and 195℃.

Surface roughness: Rougher surface and increased sagging and stringing are observed on the cone at temperatures of 230℃, 225℃, 205℃, and 210℃.

Considering the melting effciency of the flaments and reducing the risk of clogging, a higher temperature value of 220℃ is chosen.

In summary, the best printing temperature for TPR65A filament with a diameter of 2.85 mm and a nozzle diameter of 0.8 mm is 220℃.

- Temperature of printing platform

flow rate

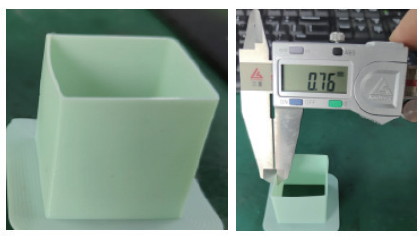

flow rate affects the amount of material extruded. If the flow rate is too low, cavities may appear in the printed object; if it is too high, the surface of the printed object may have uneven linear textures.

Print a hollow cube with a side length of 30 mm and a height of 30 mm, and a shell thickness of 0.8 mm. Measure the shell thickness after printing. Divide the theoretical shell thickness by the measured shell thickness to obtain the flow rate, which is calculated as 105% based on a measured shell thickness of 0.76 mm.

f=0.8/0.76*100%=105%

5.3.6.Speed Setting

Using flexible flament for shoe printing is the key focus of this design. A single shoe weighs between 200-300 g, and once support is added the entire shoe weighs around 400-500 g.

The speed range of the speed tower model is from 20-90 mm/s with increments of 10mm/s.

Result analysis Result analysis mainly considers interlayer adhesion, surface roughness, and effciency.

(1)Interlayer adhesion: When the speed exceeds 50 mm/s, there is insuffcient extrusion, resulting in cracking between layers.

(2)Surface roughness: At speeds above 50 mm/s, the surface roughness of the hemisphere is relatively high.

Efficiency: The higher the speed, the higher the effciency. The maximum speed taken within the allowable range is 40 mm/s.

In summary, the best printing speed for TPR65A filament with a diameter of 2.85 mm and a nozzle diameter of 0.8 mm is 40 mm/s.

5.3.7.Support Setting

When the overhang angle of a printed model exceeds that of support, supports need to be added.

To reduce waste caused by supports, support density can be selected as 10 - 15%.

To facilitate easy removal, zigzag support can be selected.

An additional layer of support wall can be added to increase support strength and avoid collapse during printing.

To reduce the flament loss of support contact surface, the density of support contact surface can be set to 60% - 80%..

6.Future

In the first stage of the plan, we mainly rely on TPR filament and flexible extruders, as well as footwear model research to develop shoe-related applications and products. This stage of the plan aims to establish a foundation to ensure that our products can meet the basic needs and expectations of users.

In the second stage of the plan, we will launch more application filaments such as TPE and TPU, and also release a dedicated 3D printer using flexible filaments. In addition, customized 3D printing application models will be developed for different materials and printing processes.

At this stage, we will further expand our product line and enhance customer satisfaction. In addition to TPR, we will also introduce filaments such as TPE and TPU to meet the needs of users for different materials. We will also launch a dedicated 3D printer with higher precision and stability, aimed at meeting print quality demands. furthermore, we will develop 3D printing application models compatible with these new materials to help users easily realize their designs and creativity.

In the third stage of the plan, we will improve the precision of flexible printing, explore different 3D printing technologies such as SLA, SLS, DLP, and gradually introduce more professional applications such as medical equipment, automotive parts, electronic products, etc.

During this period, we will continuously improve our technical capabilities and market competitiveness. We will further improve the accuracy and stability of flexible printing by adjusting printing parameters, improving design, optimizing material selection, etc. We will also explore other 3D printing technologies and attempt to apply them to the printing of flexible materials, in order to diversify our product offerings. In addition, we will actively collaborate with industry clients to develop and launch more professional applications to meet diverse market demands.