Model uploaded to Creality Cloud - Creality Cloud -Engineering challenge chassis v3 (friction fit) + … From user5681115635 Engineering challenge chassis v3 (friction fit) + mounts | 3D models download | Creality Cloud

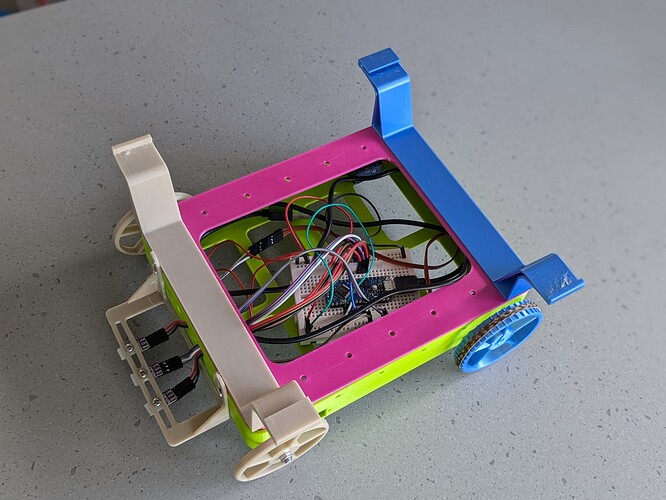

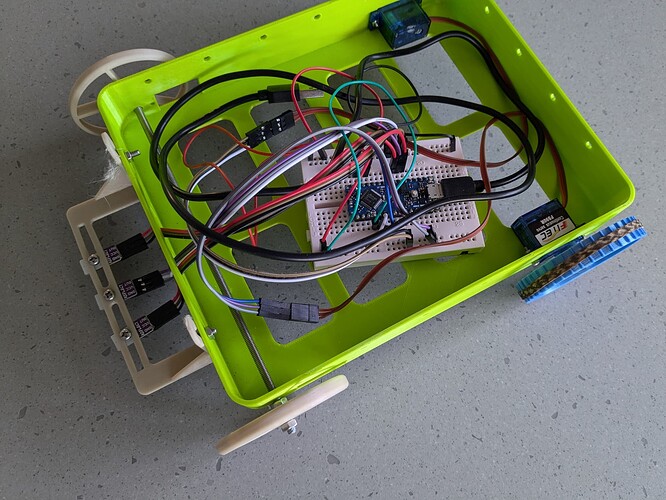

Designed as a two part friction fit chassis to avoid the need for supports.

Printing Machine: Prusa Mk3 (as only printer available at school)

Selected materials: PLA

Print settings: 0.2mm and standard settings (no supports needed as a two part friction fit lid)

Time spent on printing: circa 4 hours

Description: Two part friction fit chassis as part of school project. Details as follows (and attached)

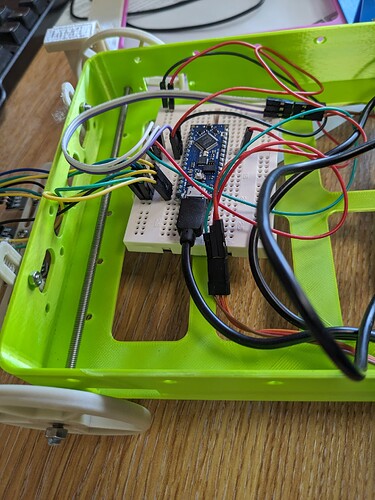

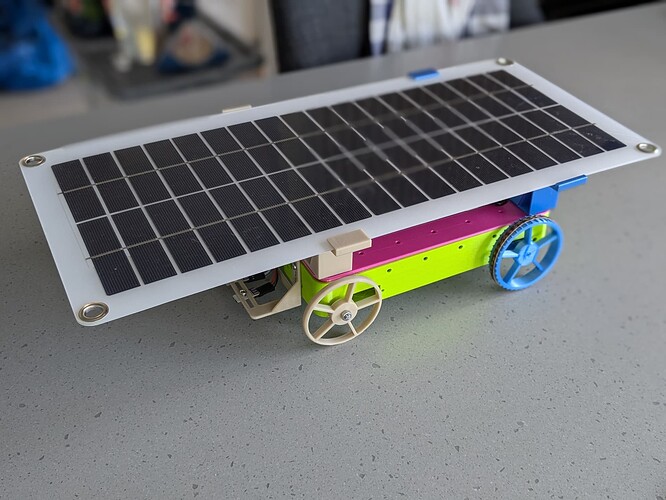

I’m a Maths teacher (11-18) in the UK and began my journey into 3D printing a year ago. This was as I created and trialled an engineering challenge for sixthform students (17-18) where from a standardised chassis, they were challenged to work as a small team of 2-4 students to create an autonomous solar powered line following robot (more detail below + videos + materials). This introduced them to a range of skills not taught in the classroom, requiring them to develop skills in 3D design, 3D printing, programming and project management. I’m passionate about multi-disciplinary integration in engineering and view 3D printing (and rapid prototyping) as a key element of this.

More photos to follow (I’m away for a few days but will update 23 Aug)

Last year I successfully trialled the engineering project with four teams using the school’s 3D printer to produce the chassis’ and print the students designed parts – solar panel mounts + their design for mount of IR sensors. They learned lots along the way, with lots of trial and improvement, and developed a range of key engineering and team working skills. I have taken a job at a new local school from September and whilst I hope to continue the project, unfortunately I won’t have the same access to 3D printers at my new school so winning a K2 Plus Combo or Ender-3 V3 would transform my ability to continue and develop the project. Assuming continued success (and refinement of the project) in the longer term I have aspirations to extend the project to other schools in my local area.

For a little more context please review the attachments provided – you’re welcome to use but please do include me as a reference on this. I’d also welcome any thoughts, feedback or development suggestions.

The whole project has come about as a response to my previous school having no Design and Technology department, but a strong STEM cohort of students. Many of these were applying to University or for apprenticeships to study Engineering or practical science degrees, but the lack of practical experience available through meant they were struggling to get through the application process. The engineering challenge was an effort to address this practical skills gap.

Provide relevant originality proof: As posted to Creality Forum (STL files provided) - Creality Cloud -Engineering challenge chassis v3 (friction fit) + … From user5681115635 Engineering challenge chassis v3 (friction fit) + mounts | 3D models download | Creality Cloud

Country/Region: UK

Examples of student produced materials:

Project briefing document - Challenge 1 v2 Y12 Jan 24.pdf (264.4 KB)

Engineering challenge - Project Charter student example.pdf (297.8 KB)

Engineering challenge - Student project presentation example 1.pdf (1.2 MB)

Engineering challenge - Student project presentation example 2.pdf (1.2 MB)