Hi guys. Just arrived at the forum. I’ve been 3D printing for 6 years now. Started with an old Tevo Tarantula, that had lots of upgrades during this time, and was a great learning experience, but now I’ve decided to add a CoreXY printer, and chose the Flagship K1.

At first I was really impressed with its performance, and apparently print quality, until I’ve noticed a problem I was unable to solve yet.

I’ve just received my printer 4 days ago, and being looking for information without success.

What happens is that I’ve printed 2 pieces of the same model at once, distributed on the bed. When I’ve removed the pieces and put them back-to-back to store, I’ve noticed that they were not straight.

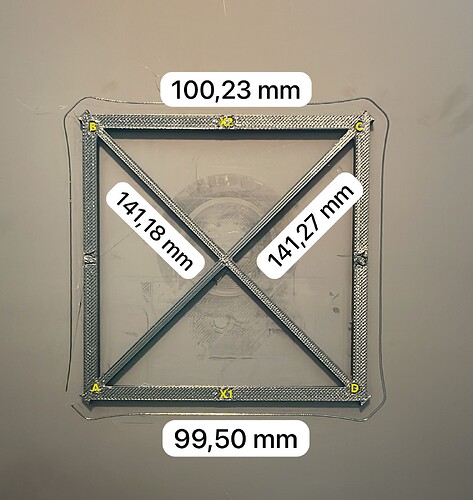

I’ve printed a skew compensation test square, and found out that I’m having more than 1mm difference in a 100mm cube, what is too much.

I’ve tried to add skew compensation line to the START GCODE, but didn’t work. Tried to reset belt tension, tuned to 110hz but didn’t help.

Looking the printer from the top, I can see that at the left side, when moving forward the print head, the distances of the axis at the corners, related to the frame, are different. X axis is not perfectly perpendicular to Y axis.

Does anyone noticed that? Any clues how to solve it? I’ve already printed an RC airplane with an entire filament roll, and when tried to connect the parts, I was unable to do it. Some surfaces have different measures, and some holes doesn’t align.

Thanks!