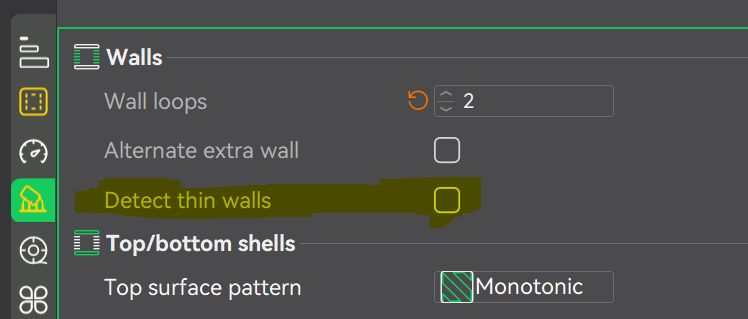

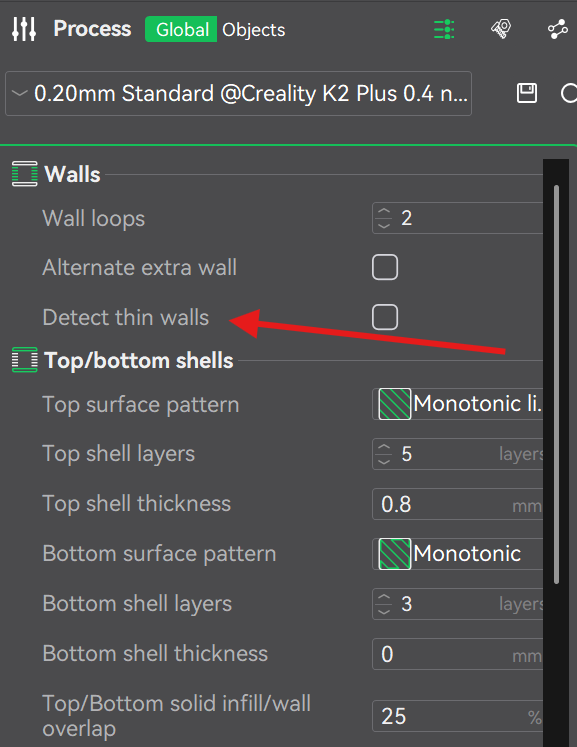

Ok, so the “Detect Thin Walls” option is only available when using the Classic Wall Generator — that’s why I couldn’t see it in my profile while using Arachne.

I’ve now switched to Classic and enabled “Detect Thin Walls.”

Here’s what I’m currently testing with:

-

Sparse Infill Anchor Length: 400% (also tried 200%, no difference)

-

Apply Gap Fill: Everywhere

-

Under Advanced: “Detect narrow internal solid infill” enabled

In the slicer preview, I notice a difference when reducing the outer wall line width, and also that orientation seems to influence how these micro-gaps get filled — depending on the angle, some of them actually close better.

@CREALITY One small UX note: I really wish the slicer would show disabled settings instead of hiding them, with a short explanation of why they’re unavailable. I spent quite a while trying to figure out why that option wasn’t showing up at all — it would save a lot of confusion!

I am printing the model now, will get back to you with the results.

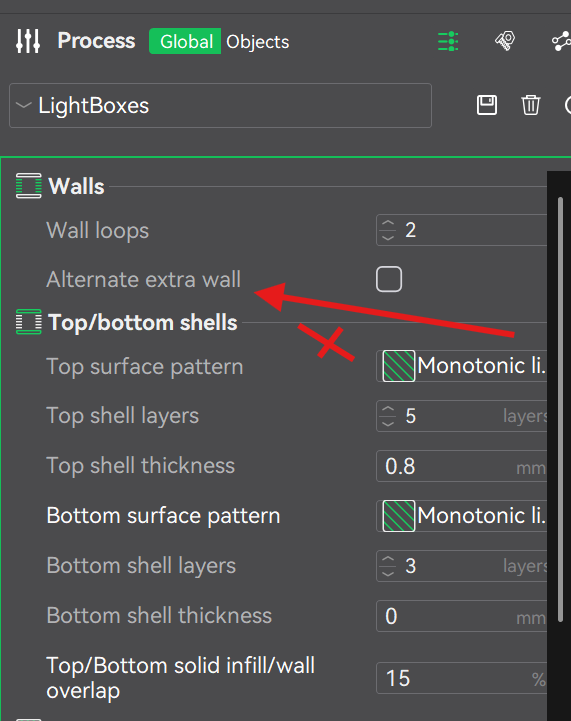

Here are my current settings:

Creality Print LightBoxes__ Profile

Creality Print LightBoxes__ Profile

Section: Quality

Section: Quality

Layer Height

Line Width

-

Default: 0.42 mm or %

-

First layer: 0.5 mm or %

-

Outer wall: 0.25 mm or %

-

Inner wall: 0.45 mm or %

-

Top surface: 0.42 mm or %

-

Sparse infill: 0.45 mm or %

-

Internal solid infill: 0.42 mm or %

-

Support: 0.4 mm or %

Seam

-

Seam position: Aligned

-

Staggered inner seams: Off

-

Seam gap: 10%

-

Scarf joint seam (beta): None

-

Role base wipe speed: On

-

Wipe speed: 80 mm/s or %

-

Wipe on loops: Off

-

Wipe before external loop: On

Precision

-

Slice gap closing radius: 0.049 mm

-

Resolution: 0.012 mm

-

Arc fitting: Off

-

X–Y hole compensation: 0 mm

-

X–Y contour compensation: 0 mm

-

Elephant foot compensation: 0 mm

-

Precise wall: Off

-

Convert holes to polyholes: Off

-

Precise Z height: Off

Ironing

Wall Generator

Walls and Surfaces

-

Walls printing order: Inner/Outer

-

Print infill first: Off

-

Wall loop direction: Auto

-

Top surface flow ratio: 1.0

-

Bottom surface flow ratio: 1.05

-

Only one wall on top surfaces: On

-

One wall threshold: 300%

-

Only one wall on first layer: On

-

Avoid crossing walls: On

-

Avoid crossing walls – Max detour length: 0 mm or %

-

Small area flow compensation (beta): On

-

Flow Compensation Model:

0,0;

0.2,0.4444;

0.4,0.6145;

0.6,0.7059;

0.8,0.7619;

1.5,0.8571;

2.0,0.8889;

3.0,0.9231;

5.0,0.9520;

Bridging

-

Bridge flow ratio: 1

-

Internal bridge flow ratio: 1

-

Bridge density: 100%

-

Thick bridges: Off

-

Thick internal bridges: On

-

Don’t filter out small internal bridges (beta): Disabled

-

Bridge counterbore holes: None

Overhangs

-

Detect overhang walls: On

-

Make overhangs printable: Off

-

Extra perimeters on overhangs: Off

-

Reverse on odd: Off

-

Overhang optimization (beta): Off

Section: Strength

Section: Strength

Walls

Top/Bottom Shells

-

Top surface pattern: Monotonic lines

-

Top shell layers: 5 layers

-

Top shell thickness: 0.8 mm

-

Bottom surface pattern: Monotonic lines

-

Bottom shell layers: 3 layers

-

Bottom shell thickness: 0 mm

-

Top/Bottom solid infill/wall overlap: 15%

Infill

-

Sparse infill density: 15%

-

AI infill: Off

-

Sparse infill pattern: CrossHatch

-

Sparse infill anchor length: 400% mm or %

-

Maximum infill anchor length: 20 mm or %

-

Internal solid infill pattern: Monotonic lines

-

Apply gap fill: Everywhere

-

Filter out tiny gaps: 0 mm

-

Infill/wall overlap: 15%

-

Anchor solid infill by X mm: 0 mm or %

Advanced

-

Sparse infill direction: 45°

-

Solid infill direction: 45°

-

Rotate solid infill direction: On

-

Bridge infill direction: 0°

-

Minimum sparse infill threshold: 15 mm²

-

Infill combination: Off

-

Detect narrow internal solid infill: On

-

Ensure vertical shell thickness: All

Section: Speed

Section: Speed

First Layer Speed

Other Layers Speed

Overhang Speed

-

Slow down for overhangs: On

-

Classic mode: Off

-

Slow down for curled perimeters: On

-

Overhang speed map:

-

0 mm/s or % (10%, 25%)

-

50 mm/s or % [25%, 50%]

-

30 mm/s or % [50%, 75%]

-

10 mm/s or % [75%, 100%]

-

Bridge: 50 mm/s (External)

-

Internal bridge: 150%

Travel Speed

Acceleration

-

Normal printing: 8000 mm/s²

-

Outer wall: 5000 mm/s²

-

Inner wall: 5000 mm/s²

-

Bridge: 50% mm/s² or %

-

Sparse infill: 100% mm/s² or %

-

Internal solid infill: 100% mm/s² or %

-

First layer: 500 mm/s²

-

Top surface: 2000 mm/s²

-

Travel: 8000 mm/s²

-

Accel to decel: 50%

Jerk (XY)

-

Default: 8 mm/s

-

Outer wall: 8 mm/s

-

Inner wall: 8 mm/s

-

Infill: 8 mm/s

-

Top surface: 8 mm/s

-

First layer: 8 mm/s

-

Travel: 8 mm/s

Advanced

-

Extrusion rate smoothing: 0 mm³/s²

-

Weight limit speed & acceleration: Set

-

Height limit speed & acceleration: Set

Section: Supports

Section: Supports

- All support options: Disabled for this preset

Section: Multifilament

Section: Multifilament

Prime Tower

-

Enable: On

-

Width: 40 mm

-

Prime volume: 50 mm³

-

Brim width: 3 mm

-

Prime tower rotation angle: 0°

-

Prime tower enhance type: Chamfer

-

Extra flow for purging: 100%

-

No sparse layers (beta): Off

Flush Options

Advanced

-

Use beam interlocking: Off

-

Maximum width of segmented region: 0 mm

-

Interlocking depth of segmented region: 0 mm

Section: Others

Section: Others

Skirt

Brim

-

Brim type: No-brim

-

Brim width: 5 mm

-

Brim-object gap: 0.3 mm

Special Mode

G-code Output

Post-processing Scripts

Notes

Filament Profiles

Filament Profile: PLA+_DarkYellow (eSUN)

Filament Profile: PLA+_DarkYellow (eSUN)

Basic Information

-

Type: PLA

-

Vendor: eSUN

-

Soluble filament: No

-

Filament for supports: No

-

Required nozzle HRC: 0

-

Default color: Yellow (#FFFF00)

-

Diameter: 1.75 mm

-

Flow ratio: 0.9765

-

Enable pressure advance:

-

Pressure advance: 0.056

-

Density: 1.23 g/cm³

-

Shrinkage (XY / Z): 100% / 100%

-

Price: 20 money/kg

-

Softening temperature: 53 °C

-

Idle temperature: 0 °C

Temperature Settings

-

Recommended nozzle temp: 205 – 215 °C

-

Chamber temp: 35 °C (active control on, layer 1)

-

Nozzle temperature:

-

First layer: 210 °C

-

Other layers: 205 °C

-

Bed temperature (Smooth/Textured/Custom Plate):

-

First layer: 55 °C

-

Other layers: 55 °C

-

Epoxy resin plate: 45 °C

-

Max volumetric speed: 10 mm³/s

Cooling

-

No cooling for first layers: 0

-

Model fan speed:

-

Keep fan always on:

-

Slow printing for better layer cooling:

-

Don’t slow down outer walls:

-

Smart cooling zones (Beta):

-

Min print speed: 20 mm/s

-

Force cooling for overhangs/bridges:

-

Cooling overhang threshold: 50 %

-

Fan speed for overhangs: 100 %

-

Support interface fan speed: -1 % (default)

-

Side fan speed: 80 %

-

Special area cooling:  (100 % if enabled)

(100 % if enabled)

-

Auxiliary fan opening height: 0.5 mm

-

Back fan (air filtration): Off

-

During print: 60 %

-

After print: 80 %

Retraction (Setting Overrides)

-

Retraction length: 1.8 mm

-

Z hop: 0.4 mm (type: Spiral)

-

Retraction speed: 40 mm/s

-

Deretraction speed: 40 mm/s

-

Extra length on restart: 0 mm

-

Travel distance threshold: 1 mm

-

Retract on layer change:

-

Wipe while retracting:

-

Wipe distance: 2 mm

-

Retract amount before wipe: 70 %

-

Long retraction when cut (experimental):

Advanced

Filament Start G-code

;filament start gcode

{if (position[2] > first_layer_height) }

M104 S[nozzle_temperature]

{else}

M104 S[first_layer_temperature]

{endif}

{if(initial_extruder != current_extruder || position[2] > first_layer_height)}

{if (position[2] +0.4 < printable_height) }

G2 Z{position[2] + 0.4} I0.86 J0.86 P1 F10000 ; spiral lift a little from second lift

G1 X205 Y345 F20000

G1 Z{position[2] } F1200

{else}

G1 X205 Y345 F20000

{endif}

{endif}

Filament End G-code

;filament end gcode

Multifilament

-

Minimal purge on wipe tower: 30 mm³

-

Enable ramming for multitool:

-

Multitool ramming volume: 10 mm³

-

Multitool ramming flow: 10 mm³/s

Filament Profile: Pla_DarkPurple (Voxelab)

Filament Profile: Pla_DarkPurple (Voxelab)

Basic Information

-

Type: PLA

-

Vendor: Voxelab

-

Soluble filament: No

-

Filament for supports: No

-

Required nozzle HRC: 0

-

Default color: Dark Purple (#800080)

-

Diameter: 1.75 mm

-

Flow ratio: 0.9405

-

Enable pressure advance:

-

Pressure advance: 0.06

-

Density: 1.25 g/cm³

-

Shrinkage (XY / Z): 100% / 100%

-

Price: 20 money/kg

-

Softening temperature: 110 °C

-

Idle temperature: 0 °C

Temperature Settings

-

Recommended nozzle temp: 190 – 220 °C

-

Chamber temp: 35 °C (active control on, layer 1)

-

Nozzle temperature:

-

First layer: 210 °C

-

Other layers: 215 °C

-

Bed temperature (Smooth/Textured Plate):

-

First layer: 50 °C

-

Other layers: 50 °C

-

Customized Plate: 35 °C

-

Epoxy Resin Plate: 40 °C

-

Max volumetric speed: 14 mm³/s

Cooling

-

No cooling for first layers: 1

-

Model fan speed:

-

Keep fan always on:

-

Slow printing for better layer cooling:

-

Don’t slow down outer walls:

-

Smart cooling zones (Beta):

-

Min print speed: 20 mm/s

-

Force cooling for overhangs/bridges:

-

Cooling overhang threshold: 50 %

-

Fan speed for overhangs: 100 %

-

Support interface fan speed: -1 % (default)

-

Side fan speed: 80 %

-

Special area cooling:  (100 % if enabled)

(100 % if enabled)

-

Auxiliary fan opening height: 0.5 mm

-

Back fan (air filtration): Off

-

During print: 60 %

-

After print: 80 %

Retraction (Setting Overrides)

-

Retraction length: 1.8 mm

-

Z hop: 0.4 mm (type: Spiral)

-

Retraction speed: 40 mm/s

-

Deretraction speed: 40 mm/s

-

Extra length on restart: 0 mm

-

Travel distance threshold: 1 mm

-

Retract on layer change:

-

Wipe while retracting:

-

Wipe distance: 2 mm

-

Retract amount before wipe: 70 %

-

Long retraction when cut (experimental):

Advanced

Filament Start G-code

;filament start gcode

{if (position[2] > first_layer_height) }

M104 S[nozzle_temperature]

{else}

M104 S[first_layer_temperature]

{endif}

{if(initial_extruder != current_extruder || position[2] > first_layer_height)}

{if (position[2] +0.4 < printable_height) }

G2 Z{position[2] + 0.4} I0.86 J0.86 P1 F10000 ; spiral lift a little from second lift

G1 X205 Y345 F20000

G1 Z{position[2] } F1200

{else}

G1 X205 Y345 F20000

{endif}

{endif}

Filament End G-code

;filament end gcode

Multifilament

-

Minimal purge on wipe tower: 30 mm³

-

Enable ramming for multitool:

-

Multitool ramming volume: 10 mm³

-

Multitool ramming flow: 10 mm³/s

Filament Profile: HyperPLA_White (Creality)

Filament Profile: HyperPLA_White (Creality)

Basic Information

-

Type: PLA

-

Vendor: Creality

-

Soluble filament: No

-

Filament for supports: No

-

Required nozzle HRC: 0

-

Default color: White (#FFFFFF)

-

Diameter: 1.75 mm

-

Flow ratio: 0.9408

-

Enable pressure advance:

-

Pressure advance: 0.076

-

Density: 1.24 g/cm³

-

Shrinkage (XY / Z): 100% / 100%

-

Price: 20 money/kg

-

Softening temperature: 60 °C

-

Idle temperature: 0 °C

Temperature Settings

-

Recommended nozzle temp: 190 – 240 °C

-

Chamber temperature: 35 °C (active control on, layer 1)

-

Nozzle temperature:

-

First layer: 210 °C

-

Other layers: 215 °C

-

Bed temperature:

-

Smooth PEI / High-Temp Plate → 50 °C

-

Textured PEI Plate → 50 °C

-

Customized Plate → 35 °C

-

Epoxy Resin Plate → 40 °C

-

Max volumetric speed: 23 mm³/s

Cooling

-

No cooling for first layers: 0

-

Model fan:

-

Keep fan always on:

-

Slow printing for layer cooling:

-

Don’t slow down outer walls:

-

Smart cooling zones (Beta):

-

Min print speed: 20 mm/s

-

Force cooling for overhangs/bridges:

-

Cooling overhang threshold: 50 %

-

Fan speed for overhangs: 100 %

-

Support interface fan speed: -1 %

-

Side fan: 80 %

-

Special area cooling:  (100 % if enabled)

(100 % if enabled)

-

Auxiliary fan opening height: 0.5 mm

-

Back fan: off (air filtration disabled)

-

During print → 60 %

-

After print → 80 %

Retraction (Setting Overrides)

-

Length: 1.8 mm

-

Z hop: 0.4 mm (Spiral)

-

Retraction speed: 40 mm/s

-

Deretraction speed: 40 mm/s

-

Extra length on restart: 0 mm

-

Travel distance threshold: 1 mm

-

Retract on layer change:

-

Wipe while retracting:

-

Wipe distance: 2 mm

-

Retract amount before wipe: 70 %

-

Long retraction when cut (experimental):

Advanced

Filament Start G-code

;filament start gcode

{if (position[2] > first_layer_height) }

M104 S[nozzle_temperature]

{else}

M104 S[first_layer_temperature]

{endif}

{if(initial_extruder != current_extruder || position[2] > first_layer_height)}

{if (position[2] +0.4 < printable_height) }

G2 Z{position[2] + 0.4} I0.86 J0.86 P1 F10000 ; spiral lift a little from second lift

G1 X205 Y345 F20000

G1 Z{position[2] } F1200

{else}

G1 X205 Y345 F20000

{endif}

{endif}

Filament End G-code

;filament end gcode

Multifilament

-

Minimal purge on wipe tower: 30 mm³

-

Enable ramming for multitool:

-

Multitool ramming volume: 10 mm³

-

Multitool ramming flow: 10 mm³/s

Filament Profile: HyperPLA_Black (Creality)

Filament Profile: HyperPLA_Black (Creality)

Basic Information

Type: PLA

Vendor: Creality

Soluble filament: No

Filament for supports: No

Required nozzle HRC: 0

Default color: Black (#000000)

Diameter: 1.75 mm

Flow ratio: 0.9408

Enable pressure advance:

Pressure advance: 0.040

Density: 1.24 g/cm³

Shrinkage (XY / Z): 100% / 100%

Price: 20 money/kg

Softening temperature: 60 °C

Idle temperature: 0 °C

Temperature Settings

Recommended nozzle temp: 190 – 240 °C

Chamber temperature: 35 °C (active control on, layer 1)

Nozzle temperature:

First layer: 205 °C

Other layers: 200 °C

Bed temperature:

Smooth PEI / High-Temp Plate → 50 °C

Textured PEI Plate → 50 °C

Customized Plate → 35 °C

Epoxy Resin Plate → 40 °C

Max volumetric speed: 23 mm³/s

Cooling

No cooling for first layers: 0

Model fan:

Min = 100 % @ 100 s layer time

Max = 100 % @ 6 s layer time

Keep fan always on:

Slow printing for layer cooling:

Don’t slow down outer walls:

Smart cooling zones (Beta):

Min print speed: 20 mm/s

Force cooling for overhangs/bridges:

Cooling overhang threshold: 50 %

Fan speed for overhangs: 100 %

Support interface fan speed: -1 %

Side fan: 80 %

Special area cooling:  (100 % if enabled)

(100 % if enabled)

Auxiliary fan opening height: 0.5 mm

Back fan: off (air filtration disabled)

During print → 60 %

After print → 80 %

Retraction (Setting Overrides)

Length: 1.8 mm

Z hop: 0.4 mm (Spiral)

Retraction speed: 40 mm/s

Deretraction speed: 40 mm/s

Extra length on restart: 0 mm

Travel distance threshold: 1 mm

Retract on layer change:

Wipe while retracting:

Wipe distance: 2 mm

Retract amount before wipe: 70 %

Long retraction when cut (experimental):

Advanced

Filament Start G-code

;filament start gcode

{if (position[2] > first_layer_height) }

M104 S[nozzle_temperature]

{else}

M104 S[first_layer_temperature]

{endif}

{if(initial_extruder != current_extruder || position[2] > first_layer_height)}

{if (position[2] +0.4 < printable_height) }

G2 Z{position[2] + 0.4} I0.86 J0.86 P1 F10000 ; spiral lift a little from second lift

G1 X205 Y345 F20000

G1 Z{position[2] } F1200

{else}

G1 X205 Y345 F20000

{endif}

{endif}

Filament End G-code

;filament end gcode

Multifilament

Minimal purge on wipe tower: 30 mm³

Enable ramming for multitool:

Multitool ramming volume: 10 mm³

Multitool ramming flow: 10 mm³/s

Plate Settings

Plate name: (blank)

Bed type: Same as Global Plate Type

Print sequence: Same as Global Print Sequence

Spiral vase: Same as Global

First layer filament sequence: Customize

→ White → Yellow → Purple → Black

Other layer filament sequence: Customize

Layers: 2 to End

→ White → Yellow → Purple → Black

Flushing Volume Matrix

Flushing Volumes for Filament Change

CrealityPrint will re-calculate your flushing volumes every time the filament color changes.

Flushing Volume Matrix (mm³):

| From → To |

Yellow |

Purple |

White |

Black |

| Yellow |

0 |

599 |

1200 |

599 |

| Purple |

1200 |

0 |

1200 |

599 |

| White |

599 |

599 |

0 |

599 |

| Black |

1200 |

1200 |

1200 |

0 |

Notes:

-

Flushing volume (mm³) for each filament pair

-

Suggested flushing volume range: 183–1200 mm³

-

Suggestion: flushing between different filament types > 549 mm³

-

Multiplier: 1.30