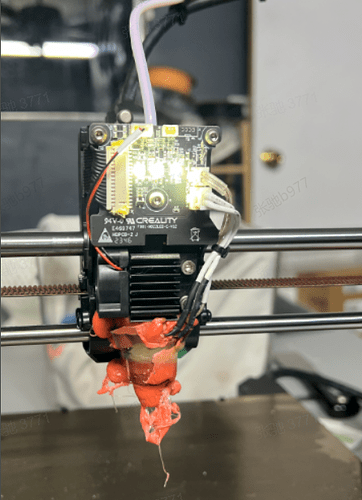

During the printing process of the machine, the filament overflows near the nozzle/the filament covers the nozzle.

During the printing process, the first layer of the model did not stick to the platform and was carried away by the nozzle, causing the nozzle outlet to be blocked and the filament to cover the nozzle.

Check whether the nozzle heating function is normal.

3.1 If normal, heat the nozzle to 300°.

-

3.1.1 Clean the filament near the nozzle fan cover, refer to the video on replacing the nozzle kit, and remove the fan cover. (Note here that the fan cable is unplugged after the power is disconnected)

-

3.1.2 Reheat to 300° and clean the spill near the nozzle.

-

Note: Some areas cannot be melted by heating, you can use a heat gun/hair dryer to assist with heating.

-

3.1.3 Replace damaged parts, such as fan covers, air guides, etc., and reinstall them.

3.2 If the heating function is abnormal, unable to heat.

-

3.2.1 Check whether the fan cover can be disassembled. If the fan cannot be disassembled due to overflow, you need to use a heat gun/hair dryer to clean the filament.

-

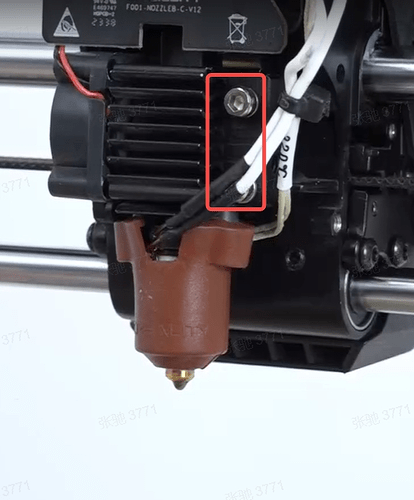

3.2.2 Since it cannot be heated, you need to remove the nozzle kit with the heat sink block. (Just loosen the 2 screws selected in the picture below)

- 3.2.3 Replace damaged parts, such as nozzle kits, fan shrouds, air guides, etc., and reinstall them.