An American father-son duo brought a Lamborghini supercar to life using 3D printing technology. The inspiration for this remarkable project stemmed from their shared passion for both video games and cars.

The Origin of the Father-Son Project

Sterling Backus, a PhD laser physicist and passionate father, shares a love for video games with his son, Xander. Together, they often drove a Lamborghini Aventador virtually on Xbox. One day, Xander asked his father if they could work on a project together that would help him learn about mechanics, cars, and stuff like changing oil and tires.

Inspired by this request, Sterling embarked on an ambitious car-building mission, where Xander helped clean and disassemble the engine, as well as perform welding on the car. Through this hands-on experience, Xander gained invaluable skills in mechanical work and automotive repair. At the same time, as Xander began exploring the world of 3D printing, his curiosity grew about how he could apply this new technology beyond car projects.

Practical Application of 3D Printing

In their exploration of 3D printing, Sterling and Xander leveraged additive manufacturing to create two supercar bodies. One was a Lamborghini SVJ, built entirely from scratch using 3D printing. The other was a McLaren 600LT, which Sterling initially acquired from a junkyard. After sourcing the necessary parts, he assembled the car. For the missing components, 3D printing proved invaluable, providing affordable and accessible replacements for parts that were otherwise costly or hard to find.

"And so using the 3D printer really helps us save time and money. "

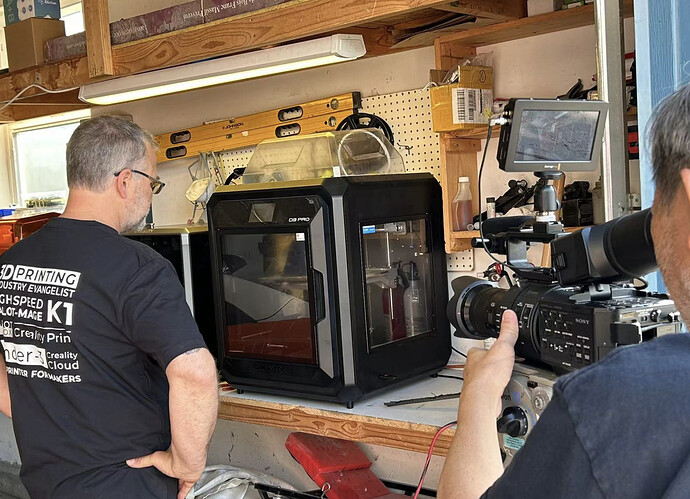

Sterling initially relied on a Creality CR-10S, running it almost non-stop for over a year. To print the car, he divided the design into smaller, one-square-foot sections, which he then printed and assembled with epoxy. The process was like building a car from jigsaw puzzle pieces—an approach they found incredibly satisfying, both creatively and emotionally.

Their experience became even more efficient when Sterling upgraded his garage with the K1 Max and Sermoon D3 3D printers. These larger-format 3D printers increased their printing speed by three times, enabling them to produce parts in hours instead of days. Moreover, the K1’s capability to print nylon carbon fiber allowed them to create more complex, mechanical components, such as folding side mirrors, enhancing the overall build quality and precision of their supercar models.

The Turning Point: Lamborghini’s Recognition

Sterling and Xander’s project quickly gained significant media attention, eventually leading to an unexpected call from Lamborghini’s headquarters in Sant’Agata Bolognese. Not only did they recognize the use of 3D printing, but they were also intrigued by the father-son dynamic behind the project. The story reached the directors of Lamborghini, who subsequently contacted Sterling through the chief marketing officer.

Initially, Sterling was concerned about potential copyright infringement, but those on the other end of the line reassured him that there were no issues. In fact, they were so impressed with the project and its story that they expressed a desire to support it. This led to an exciting collaboration, with Sterling and his son being invited to work together on a Christmas commercial for Lamborghini in 2019:A true Christmas story for Lamborghini’s Real Lovers.

From Personal Project to Community Sharing

Following the success of the commercial campaign, Sterling and Xander launched a YouTube channel where they shared their car projects and showcased the versatility of 3D printing. Their channel became a hub for a growing community, where enthusiasts could learn from each other and explore new possibilities.

Sterling highlighted one of the key advantages of 3D printing: the ability to design models efficiently. “(Designing the models) That is usually done in some sort of CAD software program,” he explained. “You can see the full car here, but I only actually have to design half the car because then I can just mirror it onto the other side.”

Future Plans and Broader Impact

Sterling has set ambitious goals for the project, aiming to 3D print the body panels for both the Lamborghini and McLaren, with plans to cover them in carbon fiber. Additionally, they intend to incorporate composite work, paint the cars, and take them on tour to demonstrate the incredible potential of 3D printing within the car community, showcasing its impact on creators and enthusiasts alike.

Sterling also envisions taking these vehicles to local schools as part of a STEM or STEAM initiative, inspiring students by showing how science, technology, and 3D printing can bring something as extraordinary as these supercars to life.

Reflecting on the growth of 3D printing in the United States, Sterling notes that it is still in its early stages. However, the technology is already gaining traction in schools, with students discovering how 3D printing is applied to everyday objects. More and more students in middle school, high school, and college are gaining exposure to the technology. Particularly as people realize that 3D printing isn’t limited to making small figurines, it is becoming increasingly popular.

“You can actually now make usable pieces. Like you can make a coat hanger, you can make a bookshelf, you can do a lot of different things around the home. Not just 3D printing supercars,” Sterling adds.

Conclusion and Inspiration

This father-son project not only showcases the immense potential of 3D printing technology but also highlights the powerful intersection of innovation, education, and family bonding. By combining their passion for cars and video games with cutting-edge 3D printing, Sterling and Xander have created more than just a model supercar—they have built a bridge to creativity, learning, and shared experiences. This project emphasizes the educational value of 3D printing, allowing young minds to engage with science, technology, and engineering in a hands-on way.

As we look toward the future, this journey serves as an inspiring example of how 3D printing can be used to transform dreams into reality. It is a tool that invites exploration and innovation, encouraging individuals of all ages to think outside the box. Whether you are a beginner or a seasoned maker, 3D printing provides an exciting avenue for creativity and problem-solving. We encourage readers to explore this fascinating technology, as it offers boundless opportunities to learn, create, and bring ideas to life.