Tensile strength is a fundamental property of materials that determines their resistance to breaking under tension. It plays a crucial role in various industries, from engineering and construction to 3D printing and manufacturing.

This article will cover the definition, formula, and practical applications of tensile strength, as well as how it is tested in different materials.

What is Tensile Strength?

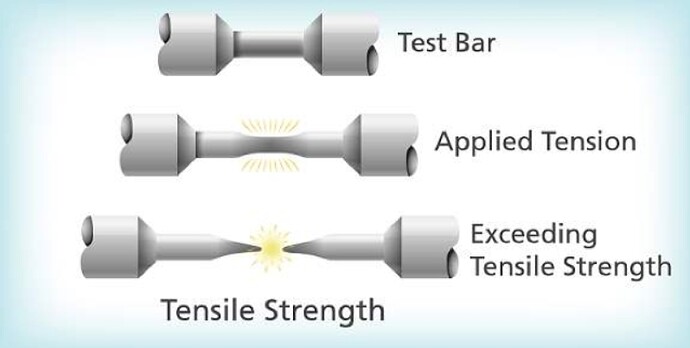

Tensile strength, also known as ultimate tensile strength (UTS), refers to the maximum amount of tensile (pulling or stretching) stress a material can withstand before it breaks. It is measured in units of force per unit area, typically megapascals (MPa) or pounds per square inch (psi).

Key points about tensile strength:

- Determines how much force a material can handle before failure.

- Used in selecting materials for bridges, buildings, automotive parts, and 3D printing.

- Different materials have different tensile strengths based on their composition and structure.

Tensile Strength Formula

The tensile strength of a material is calculated using the following formula:

Where:

- σ = Tensile strength (MPa or psi)

- F = Applied force at the point of failure (Newtons or pounds-force)

- A = Cross-sectional area of the material (square meters or square inches)

For example, if a material experiences a breaking force of 10,000 N over a cross-sectional area of 0.005 m² , the tensile strength is:

σ = 10,000 ÷ 0.005 = 2,000,000 Pa = 2 MPa

Tensile Strength Testing Methods

Tensile strength is determined using standardized testing methods. The most common procedure involves a tensile test, where a sample material is pulled until it fractures.

1. Universal Testing Machine (UTM) Test

- A sample is clamped at both ends and stretched until it breaks.

- The machine records force and elongation to calculate tensile strength.

2. Stress-Strain Curve

- A graph that plots stress (σ) vs. strain (ε) is generated.

- The highest point on the curve represents the ultimate tensile strength (UTS).

3. ASTM & ISO Standards

- Common standards for tensile testing include ASTM D638 (plastics), ASTM E8 (metals), and ISO 527.

Factors Affecting Tensile Strength

Several factors can influence the tensile strength of a material:

- Composition: The elements and compounds that make up a material.

- Temperature: Materials may become more brittle or ductile at different temperatures.

- Processing: Methods like heat treatment can alter tensile properties.

- Strain Rate : The speed at which a material is deformed can affect its tensile strength.

Tensile Strength of Different Materials

Different materials have varying tensile strengths based on their composition. Below is a comparison of some common materials:

| Material | Tensile Strength (MPa) | Application |

|---|---|---|

| Steel | 400 – 2500 | Construction, automotive |

| Aluminum | 70 – 700 | Aerospace, consumer goods |

| Carbon Fiber | 500 – 6000 | Aerospace, sports equipment |

| PLA | 50 – 70 | Prototyping, hobby printing |

| ABS | 40 – 60 | Mechanical parts, enclosures |

| Nylon | 40 – 80 | Gears, durable components |

Why Is Tensile Strength Important?

Tensile strength is crucial for:

- Material Selection: Choosing materials based on load-bearing requirements.

- Product Safety: Ensuring components can handle expected stresses.

- 3D Printing: Selecting filaments based on strength and flexibility.

- Manufacturing : Designing products that won’t break under stress.

Conclusion

Tensile strength is a key material property that defines how much stress a material can endure before breaking. By understanding the formula, testing methods, and material strength comparisons, engineers, designers, and manufacturers can make informed decisions for product development. Whether you’re in construction, manufacturing, or 3D printing, knowing tensile strength ensures durability and performance.