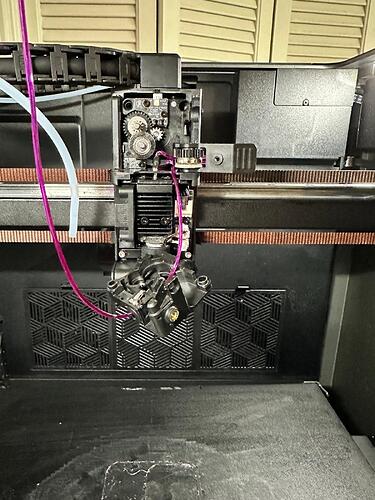

First time printing TPU, adjusted the profile according to https://www.youtube.com/watch?v=CqMtjV8Wumk but used an insert of 0.8m from 3D Printer Files | 3MF File | K2 Plus Extruder tensioner for TPU printing | Creality Cloud and a top spool holder I printed. The first layer has been quite clean and impressive but is this ticking normal?

spoiler alert, that sound was most definitely not OK. brand new front end shell (because the old one lost all of the teeth around the PTFE tubing) broken but probably still usable. Hard to keep positive when having a printer since December that the only thing it’s consistent with is being inconsistent. I’m sure the people at creality couldn’t give a care less though, as their pockets are already lined. I will never, ever buy a creality product again. I don’t want my tone to be taken as an angry one or knee-jerk reaction - this is a calm, focused view that I’m sure many share because I’ve read the other horror stories. If I were bleeding out, and there was a crealty tourniquet - I would take my chances and wait for a more reputable company to release one.

It doesn’t help you much but this why I have kept my old CR10S Pro as this prints TPU really nicely.

Maybe I’m wrong, but I was under the impression that Creality says not to print TPU using the K2+.

I’d really love to print TPU on my (so far) flawlessly-working K2+, but I don’t dare because I don’t want to mess it up. My thinking is that I’ll just buy a cheap $250 printer that I can swap a TPU extruder into and dedicate that cheap printer to meet my TPU printing needs:

No, this applies for the CFS only

Ahh, OK. Didn’t realize it was for the CFS only.

Ticking usually means the gears are slipping, this is fairly normal with softer filaments or if you have too much tension on the filament.

Now, sometimes it also could mean your print head is too close to the build plate, I find I have to adjust my print head about 0.1 mm higher when printing TPU, this helps relieve some of the pressure, and for me has helped stop the “ticking” sound.

It’s possible that the top spool holder is introducing friction as well, try to make certain that the filament feeds directly into the extruder, avoid having it make any turns if possible. The shorter and more direct the path, the lower the friction will be. Also, if this spool holder uses metal bearings, they probably need to be degreased and relubricated. A high level of grease is great for skateboarding, but terrible for low-weight/low-friction use.

It is also possible that the TPU is too damp, did you dry it? I usually find TPU to be around 35% humidity out the the box, I usually dry it to under 15% before printing and I generally only print it directly from my custom low-friction dryboxes. Wet TPU tends to be more flexible and bunches up in the gears easier.

TPU is generally so soft it’s not likely to damage the gears directly, like something with Carbon Fiber might do, but it could potentially bunch up and wrap itself around them.

Also, if you’re using a lower shore value TPU like 85a, this is pretty much the limit of softness for most mass produced printers, try something a bit harder like 95a or the less common 65d. Softer materials tend to stretch a lot more than harder ones.

Friction of any kind is your enemy here.

Things to try:

*Dry the filament (can’t stress this enough)

*Reduce distance from spool to print head

*Remove any source of friction (check friction on top spool holder by pulling filament manually off of it, if there’s any resistance, lubricate or find a different spool holder).

*Print slower, TPU prints best around 30mm/s

*If printing faster, try increasing the temperature a few degrees to help melt it quicker.

*Avoid cheaper filaments

The ticking sound, in my cases, has always meant that my nozzle is too close to the bed. A slight upwards adjustment until the ticking stops has fixed it. Your situation may be different, of course.

It still seems strange to me how many new users have all sorts of issues. I’m on my third Creality machine (K2) and have had few problems on any of them???

Almost every case of an issue has been a broken part(s)… (plastic extruder, weak bed springs, poor bed sheet) etc. OR…95% of the time, something I did wrong in setup or designing my object.

Tons of reading before buying the first one helped a lot.

I had problems printing TPU, Watson and eSUN PETG like in your second photo.

I assumed that the problem was the poor performance of the thermal barrier when the already soft plastic was heated. The problem was solved by replacing the thermal paste.

But the truth is that my negative experience should also be taken into account: if thermal paste gets on the nozzle thread, then there is a high probability that the nozzle will jam.

Therefore, I apply thermal paste with a toothpick only to the copper cylinder of the thermal barrier in the gap under the radiator of the thermal barrier. At the same time, the nozzle thread is lubricated with high-temperature copper grease.

Thanks for watching my TPU video! Glad it’s working for ya. It’s a great mod. Well once ya get your new extruder face installed lol