I’ve been trying to tune in my printers tolerances, but seem to be having issues getting them tightened up and am looking for advice. I ran the flow rate tests a couple times and think i have that mostly tuned in, but am still having issues getting tolerances to come out well.

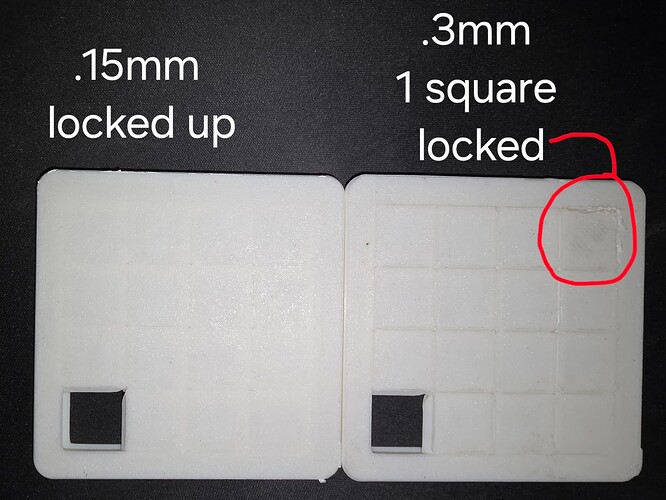

I printed a sliding puzzle that came in 3 tolerance levels. A .15mm, .2mm, and a .3mm. I started off with the .15 because of the reviews i saw online where this machine was hitting .1mm pretty consistently, and after adjusting my flow rates, i was confident. Well that was totally locked up (see attached pic). So i backed off my flow rate a couple steps and tried the .2mm. That one also was totally locked up. So i again backed off my flow rate and did the .3mm version. This one was semi locked, but i was able to free MOST of the slider squares. The only one that is totally locked up still is on one of the corners (circled in the pic).

Anyone have some advice on some more tuning and tests i can run to get this machine printing with better tolerances? Barely hitting (and kind of failing) a .3mm tolerance feels kinda poor to me…

(the marring in that circled corner was from me trying to free the square, which failed, and it remains locked in place)

Here is a link to the thingiverse file in case it sheds some light on anything.