Many thanks for your advice Gruffy.I had a quick look at OnShape a couple of weeks ago when I got the Creality Ender 3 v3 3D Printer and it looks impressive.

I had already downloaded Autodesk Fusion 360 and started bluffing my way through that. I hadn’t used any form of CAD stuff since AutoCad first came out in 1982 and for a couple of years after that but have found Fusion pretty easy going.

As I had a couple of priorities for the printer, I’ve stuck with Fusion but will have a good look in a week or two when I’ve mastered Fusion a little more.

Thanks for the link (nice work) - looks great.

Well, some since you talked about this, but thought it was worth a small update.

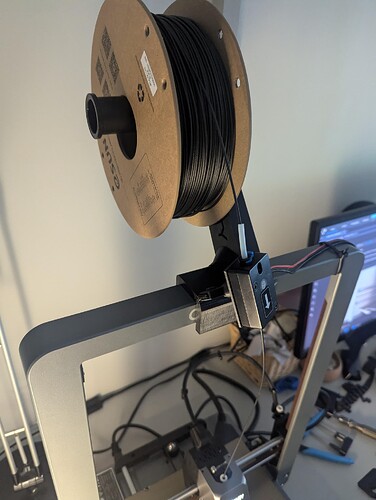

I have also been using the included (included usb stick) top spool holder without the runout sensor. However, I made a quick holder (ball mount) for attaching to the existing top spool holder. It works for me and posting it here if anyone want to test/use it.

You will need an extension cord for the runout sensor (I used a 300mm 2S battery extension cable with JST-XH connectors). You will also need 2 M3 nuts for attaching the sensor on the mount.

It has a holder that you press-fit two “nails” (plugs) into and that way it can slide in the existing filament guide. The ball-joint will make it freely spin around when the extruder moves around.

Found here: Creality Ender 3 V3 Core XZ - top runout sensor by Gruffy - Thingiverse

(Does not include the spool holder as it is not my design and it is already included on usb stick that came with the printer)

If you still have not moved the sensor maybe you would like to test this? Works nice for me at least.

Check out embracemaking.com, they have a solution to relocate the filament sensor you can print

Now that I have three different spool mounts, I could use a new spindle. There are a bunch stl files posted for Enders, but I don’t know what fits this vers. Does anyone know which one works with this Ender-3 V3 (no name core XZ)?

If you have tbe space filament drier setup feed is perfect. Not that you should have to buy one to get good feed

The creality solution doesn’t fit many e.g. eSun, Sunlu, American Filament spools.

I found my filament dryer a viable solution, though the lead out of the case is not ideal.

Gruffy’s suggestion of a spool stand sounds real good. I’ll try it.

Has anyone tried any of the auto-rewind spool holders out there?

The printing speed and pullback settings may need to be adjusted to reduce them.

Sorry Jimmy, you must not have an E3V3 (coreXZ) and don’t understand the problem. Creality E3V3 naming structure has created a lot of confusion. This printer has a runout sensor on the X crossbar and homes in the upper left corner which pulls out extra filament as the sensor rides up. When it comes down to the print bed all that extra filament is left to tangle or catch on electronics. The fix is to fix mount the filament sensor to the side rail. there are a couple mounting clip model options out there including one I posted.

If you have a spare lazy susan or record player/turntable laying around that’s not being used, place the spool on top of it (horizontally) and let it go.

Now if this has already been said/recommended before, I apologize, I just felt the need to share.