I have printed several items since I received this printer a couple of days ago very successfully.

BUT there is a definite problem with the design of the filament feed (in my opinion) The filament is very congested as it comes off the spool and into the feed line .During the motions of the set up process the filament is stretched of the spool and then allowed to coil around the base of the printer and has got caught on the stepper motor connection in that part of the printer several times.

I believe that a protector /cover is needed over the stepper motor to stop this problem .It is a little disappointing to find this problem .It looks as if the spool holder was an after thought. Apart from this problem ,I’m pretty happy with tihs pronter.

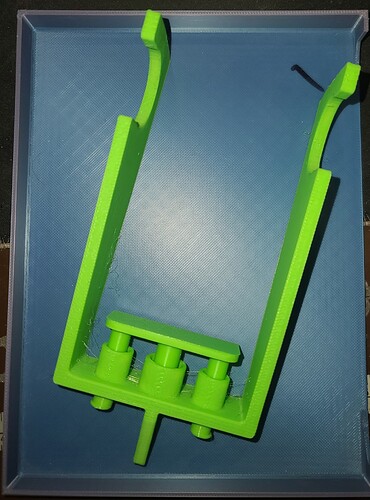

Hello @britinoz and Welcome to the Creality Forum… ![]()

![]()

On the Ender-3 V3 there is a file to print a filament holder that mounts on top. I’ve been using it but it bypasses the filament detector so it’s not perfect. I guess relocating the filament sensor would be something to work on… ![]()

I agree that the feed system needs mods. The good thing is that the frame of this Ender is much sturdier.

Greetings Jim

I am aware of the printable holder ,but up until now ,have not seen any reference to it.

Yes the frame is sturdier and I am happy with the printer BUT the filament feed is a major cock up and I am sure we should/hope see some mods soon.

Cheers

Chris…

I hope so too…!

I actually did review on the Creality FB page and asked about that.

Response:

If you run the filament from the back of the top spool it will run through up into the sensor.

I also made a cover from thin plastic card that stops the filament from contacting the wiring around the lower stepper motors.

I’ll try it that way. Thanks…! ![]()

This for me has been a rather big issue as I’ve had multiple prints fail due to the carriage moving all the way to the top unrolling the filament, then moving back down to the bed where the excess filament back-fills around the spool and then comes off and wind’s around the holder. Time and time its happened. Now, I have to sit for every print to start and as the carriage moves down, wind the filament back onto the spool so it is tight. This printer was extremely attractive as you can remote print and the print quality / functionality is so reliable, you can hit the button and walk away. Not with this issue with the filament getting tangled. The remote print is pointless if I have to walk over and monitor the printer anyways.

Did you attach the filament clip that comes with the printer. Not really a clip but it holds the filament in line and It keeps the filament from coming off. Works pretty good.

The one that comes with it is black and has small springs installed but you can print one out from the files provided…

I did but it fell off constantly during printing

Something’s wrong because it shouldn’t fall off. If you send a pic of how you have it on there maybe I can see why it’s not working…

Thanks for the picture. I have a better idea now. Try moving the filament holder back the way I have it. It should move freely as it’s not there to support the roll of filament.

Make sure the filament goes under the guide.

Sorry the pics aren’t that clear… ![]()

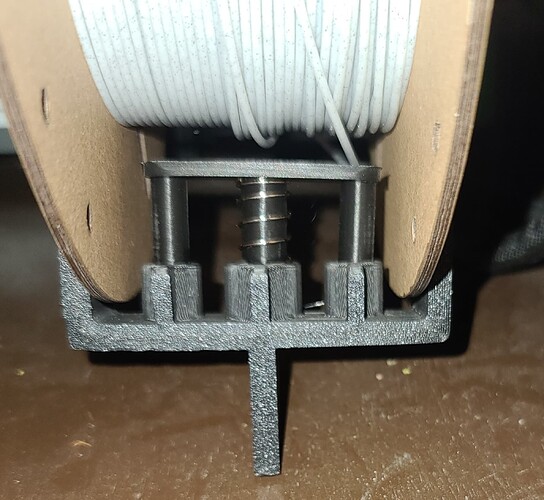

I ran the top mount for a while, then I found the side mount option.

Side Option

And how have you found the side mount option??

Thanks for the link by the way ![]()

Hi,

I have used a delta-printer for many years and now when I got this printer I changed to use what I have used with the delta, a simple spool stand (like this one: Filament Spool Holder Roller Stand Designed for 608Z bearings. by Non-ICE - Thingiverse). The benefit is that the filament thread will not come loose as the spool is rolling on its edges. I have used this simple solution for many prints now without any trouble.

Note: I am not using this exact solution. Made my own based on some old shafts/bearings I had, however, the principle is the same. Make sure to use a solution with bearings so that resistance is very low when the spool is rolling.

I have used the side mount a couple of times, and it should be better than the original location. My camera can monitor the print and the spool.

Only issue with it, so far, the spool is to close to the USB port.

It’s a sound idea so I’ll have to give it a go. I’m pretty sure I’ve got a couple of dozen of these bearings in the workshop so yeah, thanks.

I decided to print this out last night and it looks good and much more convenient in the corner I use for the printer.

I’m not too fussed about USB port access though I have plugged in a 30cm right angled extension anyway.

I will test it out this morning as I have a couple of little print jobs and a new, full spool of Hyper PLA and it’s the full spools that give me the most trouble with the original mount.

Thanks for your reply.

I will try Gruffy’s link as well because, why not? ![]()

Good luck! Make sure to look for spool stands on sites like thingiverse. The one I provided is just a sample, there are most likely some that will fit your bearings… ![]() I am using a variant where the spool is standing on longer shafts (from an rc helicopter I had). This way it can work for different sizes (width) of spools without any change.

I am using a variant where the spool is standing on longer shafts (from an rc helicopter I had). This way it can work for different sizes (width) of spools without any change.

If you are using onshape as CAD, you can have a look at my quick and dirty model here: Onshape

Please not that I am NOT a trained CAD engineer and this model is most likely not done as it should have been…however, it got me a model that works for me.

If you have not tested onshape, I would really like to recommend it.