Warpage on large flat (279X279mm) 6.35mm thick print, I am using HyperPLA and factory settings. The initial layer and a several above look perfect, but about 3mm up, the edge closest to the front of the printer starts to curl up, eventually lifting about a 50mm wide strip across the front of the print. The printer initially printed everything perfectly, then slowly developed this problem. What should I try to get this fixed?

Hey @alfredholzheu,

Welcome to the Creality Forum,

Creality K1 Max

Warping can be a problem with larger flat pieces of PLA and one thing I do to keep it at a minimum is keep the build plate at 60C, nozzle 220C, use a good adhesive (I use Bed Weld) and keep the chamber temp up a little. (31C or 32C) and try using a brim. You can’t really control the chamber temp but keep an eye on it. Mine usually stays around 30C or close to it with the top off.

There is a stronger glue called TEQStone but it really is hard to get your piece off the build plate when it’s done but if warping is really bad this stuff will stop it. Of course your mileage will vary as there are many other good adhesive out there.

Someone else here will have great ideas for controlling this warping so experiment with different ways.

I have tried all the usual suspects, but will recheck the temps on the build plate.

Just for reference

Alfred

This is one with out a brim. I did not take pics of the one with the Brim, but it essentially looked the same. I use an adhesive (supposedly a good one), have done that calibration many times, but no help.

That’s getting a little warp there.

I use a textured build plate. I don’t know if that is better or not though.

Wow…That’s a large piece where the edge is close to the fan. If I read correctly the warp happens with uneven cooling. Check the chamber temp also. Not too high there for PLA…

What are your nozzle temps…?

What are you making…? ![]()

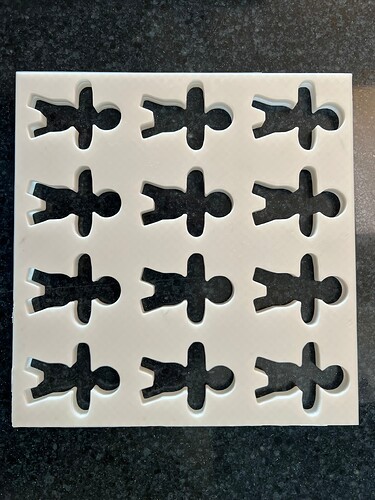

It is the roof mold for a Gingerbread House. I am working with a bakery that ships these amazing pieces of art all over the country, and they are completely edible The Solvang Bakery - Custom Gingerbread Houses and Baked Goods. The 3D printing of these molds have changed their processes completely.

Gingerbread men

Wow

That’s quite a project. Nice…

![]()

Finally got it to work, just had to increase the Bed temp by 10C and decrease the extruder head temp by 5C, added a brim (which I had done before but it had not helped), add a bit more glue to the area where it was lifting (which I had also tried before to no avail). Thanks for the sites to check out to get possible solutions and explanations as to the reasons for the problem

Great. Glad it’s working. ![]()

![]()

I’m getting hungry just thinking about that bakery you are working with… Can almost smell it… ![]()

Great example of how NOT to close a thread.

OP says parts aren’t coming out flat. Doesn’t include any settings.

Later, posts that problem is fixed by increasing bed temperature and decreasing nozzle temp, but never posts original (or final) values.