Can you imagine a world where steak lovers can enjoy their favourite dish guilt-free without the environmental and ethical concerns associated with traditional meat production? The future of food is being reshaped by technology, and one groundbreaking innovation leading the charge is 3D printing.

In this article, we’ll delve into the fascinating world of 3D printed steaks, exploring how this technology is revolutionising our food choices. Join us on this journey as we uncover the complexities of 3D printing in food manufacturing and its profound implications for the future of our plates.

- The Steak Complex

- What is 3D Printed Steak?

- Printed Steak Composition

- How Does 3D Printed Steak Work?

- Is 3D Printed Steak Vegan?

- The Future of 3D Printed Steak

The Steak Complex

Steak has long been a culinary masterpiece with its intricate mix of fat, muscle, and connective tissues. Its unique taste and texture result from a complex interplay of components that make it a challenge to replicate.

However, the seemingly impossible has become achievable with the advent of 3D printing technology. 3D-printed steaks offer a solution to traditional meat production’s environmental and ethical concerns while delivering an experience that rivals the real thing.

What is 3D Printed Steak?

3D printed steak represents a paradigm shift in the alternative protein industry. Unlike plant-based alternatives, which often struggle to replicate the texture and flavour of real meat, 3D printing allows for the precise arrangement of components to mimic the structure of conventional steak.

Whether it’s a ribeye or a tenderloin, 3D printing can fabricate any cut, shape, or size of steak with remarkable accuracy. By harnessing this technology, manufacturers can create products that look and taste like traditional steak and offer enhanced nutritional profiles.

Printed Steak Composition

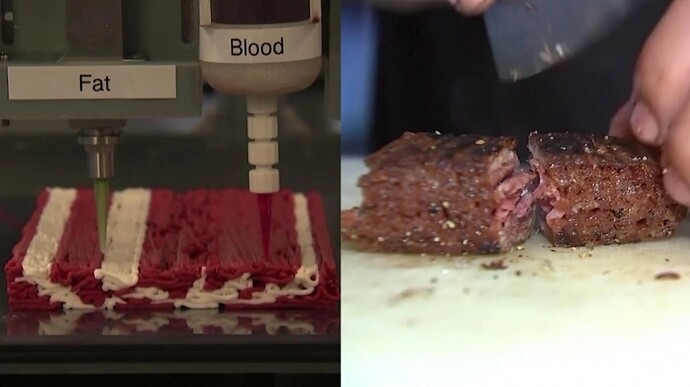

To create a convincing alternative to conventional steaks, manufacturers must carefully consider the composition of their printed steaks. Each component plays a crucial role in replicating real meat’s texture, flavour, and appearance, from muscle fibres to lipids and myoglobin.

By understanding the science behind steak, manufacturers can fine-tune their printing processes to deliver an authentic eating experience that satisfies even the most discerning palate.

Muscle Fibers

At the heart of any good steak lies its muscle fibres. These long, fibrous strands give steak its characteristic texture and mouthfeel. In 3D-printed steaks, muscle fibres are meticulously arranged using layer-by-layer printing techniques to mimic the structure of real meat.

Manufacturers can create steaks that closely resemble their animal-based counterparts by varying factors such as fibre density and alignment.

Lipids

Fat content is another crucial component of steak that contributes to its flavour and juiciness. In 3D-printed steaks, lipids are carefully integrated into the matrix to replicate the marbling effect seen in premium cuts of meat.

By controlling the fat distribution throughout the steak, manufacturers can achieve the perfect balance of flavour and texture, ensuring a satisfying dining experience for consumers.

Myoglobin

Myoglobin is the protein responsible for giving steak its characteristic red colour and rich flavour. In traditional meat production, myoglobin is naturally present in muscle tissue. In 3D-printed steaks, manufacturers may incorporate myoglobin derived from plant or animal sources to enhance the visual appeal and taste of the final product.

By carefully controlling myoglobin concentration, manufacturers can create steaks that resemble conventional meat in appearance and flavour.

How Does 3D Printed Steak Work?

3D printing starts with generating a digital design using computer-aided design/manufacturing (CAD/CAM) software. This design serves as a blueprint for printing, dictating the arrangement of layers and components.

Through techniques such as extrusion, inkjet printing, and binder jetting, 3D printers can precisely deposit materials to create intricate steak-like structures. For cultivated 3D-printed steaks, bioprinting offers a promising avenue for scalable and customisable production.

Extrusion

Extrusion is a commonly used 3D printing technique that involves forcing a material through a nozzle to create layers. In the case of 3D-printed steaks, extrusion is used to deposit muscle fibres and other structural components.

By controlling factors such as nozzle size and extrusion speed, manufacturers can create steaks with varying textures and densities, mimicking the complexity of real meat.

Binder Jetting

Binder jetting is a process whereby powdered ingredients are selectively bonded using a liquid binder. In 3D-printed steaks, binder jetting can incorporate sugars, spices, and protein powders into the matrix.

By controlling the distribution of these ingredients, manufacturers can create steaks with unique flavour profiles and nutritional compositions, offering consumers a diverse array of options.

Bioprinting

Bioprinting represents the cutting edge of 3D printing technology, offering the potential to create cultivated meat products from lab-grown cells. In bioprinting, living cells are deposited layer by layer to create tissue-like structures resembling meat.

By controlling factors such as cell type, density, and arrangement, manufacturers can create steaks with properties that closely mimic those of traditional meat, offering a sustainable and ethical alternative to conventional meat production.

Is 3D Printed Steak Vegan?

The classification of 3D-printed steak as vegan depends on various factors, including the ingredients used and the manufacturing processes employed. While some companies use exclusively plant-based ingredients, others may incorporate cultivated cells derived from animal sources.

Transparency and consumer acceptance are critical considerations for manufacturers seeking to navigate the ethical and dietary concerns surrounding printed meat alternatives.

The Future of 3D Printed Steak

As 3D printing technology continues to evolve, the future of printed steak looks brighter than ever. Innovations in printing machinery, bioprinting techniques, and ingredient sourcing promise to further enhance the quality and sustainability of printed meat alternatives.

With opportunities for customisation, scalability, and efficiency, 3D-printed steak is poised to revolutionise the alternative protein industry and reshape the way we think about food.

Conclusion

The era of 3D printed steak represents a monumental shift in how we produce and consume food. By harnessing the power of technology, manufacturers can create products that satisfy our cravings and address pressing environmental and ethical concerns. As we look to the future, it’s clear that 3D-printed steak has the potential to transform the way we eat, offering a sustainable and delicious alternative to traditional meat.

And with Creality, the possibilities are endless. Whether you’re a curious consumer or an innovative entrepreneur, now is the time to embrace the 3D revolution and explore the exciting world of printed food.