Hey Everyone,

I just received my new K2 Plus Combo about 2 weeks ago and I love this thing. I have printed dozens of items with virtually no issues and zero failures up to this point. This thing was awesome right out of the box.

For some background, my first printer was a CR5 Pro H that I bought 3 years ago. It was a disaster right out of the box. On first startup and homing the bed crashed into the print head terribly bowing it up. After a lot of scrathing my head and reading/troubleshooting I discovered the printer had a negative 18mm z offset set in it from the factory?! After fixing that it still was a terrible printer. It was a very frustrating start to 3d printing. After taking many months to learn all I could, I upgraded the extruder, mainboard, drivers, and hotend. Then and switched it over to Klipper running on Pi4 and it finally produces great prints. Needless to say I had a crash course in 3d printing and learned a lot.

So, I decided to buy the K2 Combo because I wanted the ability to print larger Asa, abs, and Nylon parts. Also the speed upgrade and the multi color option was nice a nice upgrade as well.

The slicer I used for this machine is Creality’s slicer, just updated to 6.0 this week actually. In the past I have always used Superslicer, and just recently started using Orca on my other printer.

So all has been well on everything I have printed with this machine. But most parts have been under 150mm in height. Over the past 2 days I tried printing some tall sleeves I designed for a project using polymaker asa (which printed fine on all other prints) and the prints have an issue.

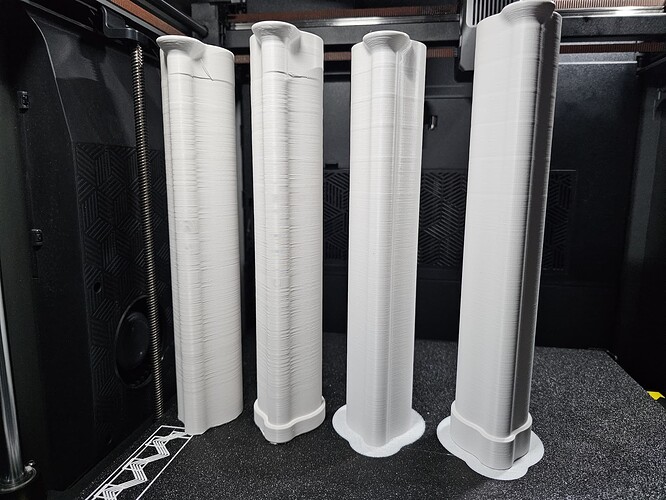

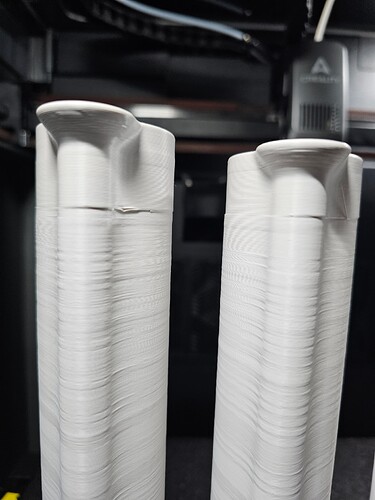

The first set I printed was at 300mms using .2 layer height and I used Crealitys Variable Layer height function set at .50 Quality/speed. I know I was pushing the speed but it worked fine on other prints. The print turned out pretty ugly, with the variable layer height making lots of adjustments through out the print because of some lettering I had designed on one side. Also there was a noticable layer shift at the very top of the print. The print finished sucessfully but it didn’t look good. This set is the left pair in the first picture. I flipped them around in the second pic so you can see the lettering I was referring too.

The next day I made some changes to the model (removed the lettering and slightly increased the height of the bottom coupler on the right print. This time all the print settings were the same other than using .28 layer height, decreasing the speed to 200mms and not using variable layer height.

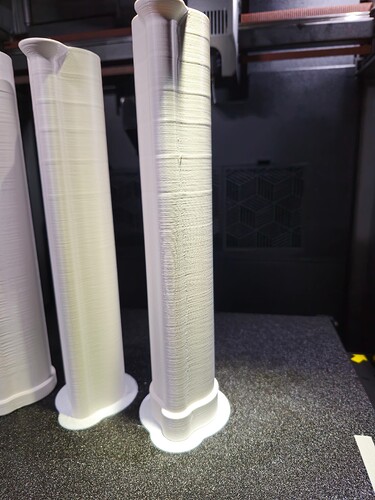

As you can see in the pics the second set looks much better, but there is still this banding pattern that starts at about 140mm in height and repeats in a decreasing distance with increasing defect throught the rest of the print. The banding is decreasing in height 1.5 to 2 mm each time it repeats, with the defect becoming more obvious each time it repeats. The pics below show this very clear because I was using very harsh lighting to show it.

This same pattern was in the first pair I printed as well, (the 2 on the left) but the banding didn’t quite line up with the second sets banding as shown in the pic below. I’m guessing the variable layer height caused this.

I’m curious what you all think may be causing this. I am leaning towards mechanical issues with the printer myself. Maybe some binding in the z axis travel, or a slightly bent lead screws for the z travel. The decreasing height in the banding pattern has me scratching my head though along with the pattern on the first set not lining up with the second. Seems to me if it was a mechanical z axis issue the pattern would match on all 4. Here’s another pic of the group.

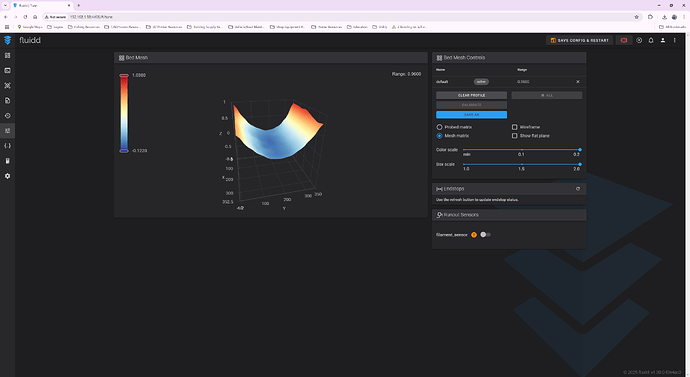

I just want to add that bed adhesion was not an issue, I had to pry these parts of the build plate. Also the printer was fully calibrated with it passing all the steps. If there is anything else I can add to this to help just let me know.

Any help would be appreciated