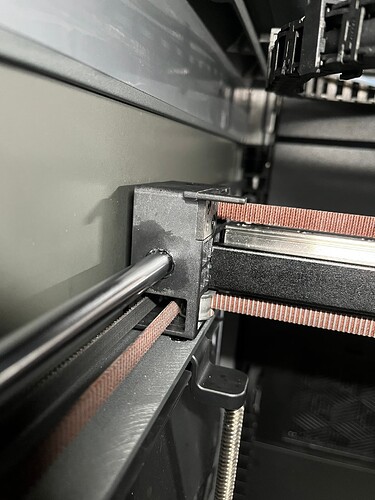

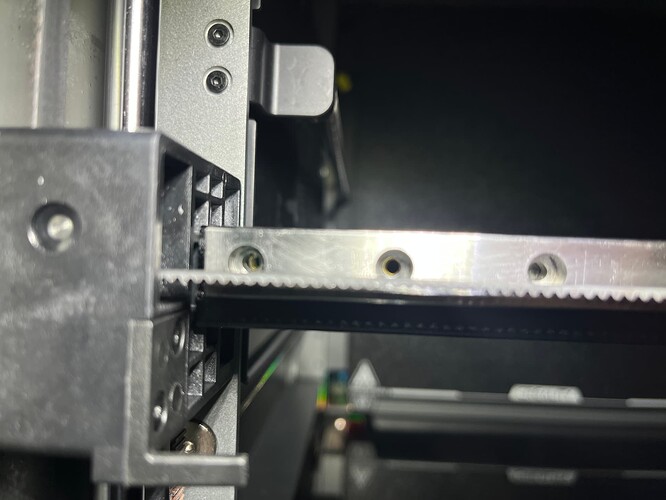

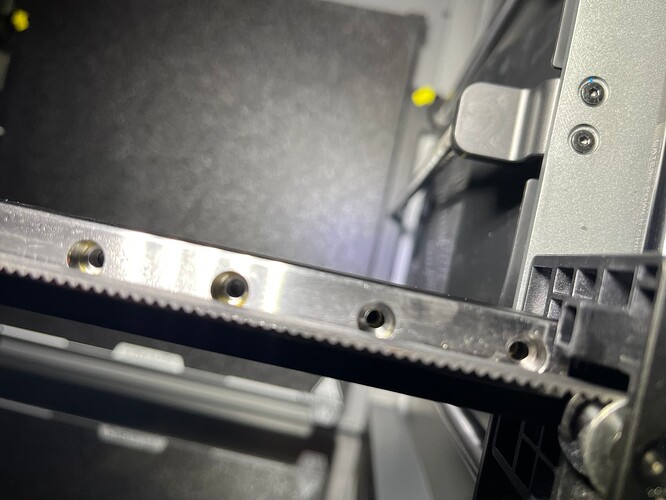

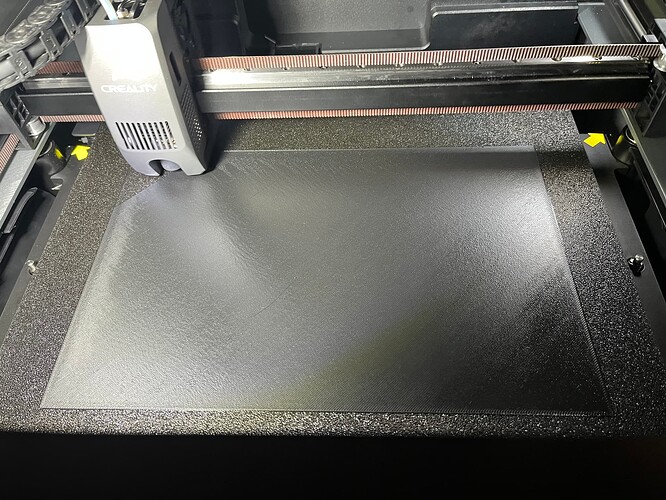

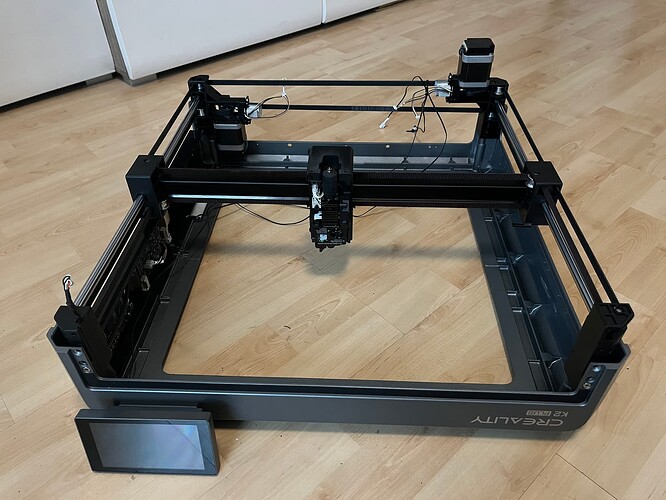

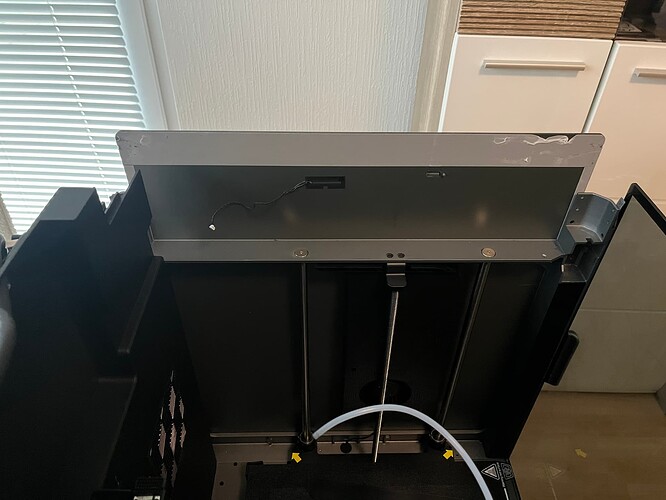

I found the error and it is a big mistake by Creality or rather the absolute worst case scenario, as it is mechanical because the 20x20mm square tube on which the MGN9 rail sits is too long or the thread position is not manufactured precisely.

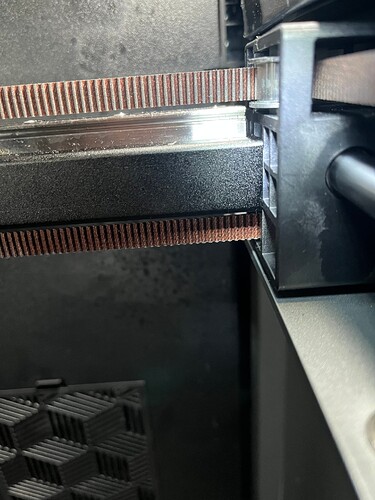

The square tube, which is screwed to the side guide with 4 screws on the left and right, presses into the side guide on the right side because the threads are not flush at the top and if you screw the screws into the thread with a bit of force, you press into the side guide and have tension, which then has an effect when printing, you could avoid the whole thing if the tube was simply 0.5mm shorter on the left and right.

But Creality has not provided for the MGN9 rail, let alone the square tube, to be able to be unscrewed, unless you remove the upper part, but that is not easy because the side parts are glued and I cannot get to the necessary screws, so I can’t do anything for now because of the warranty claim, as this is a major intervention on the printer and Creality has not yet contacted me.

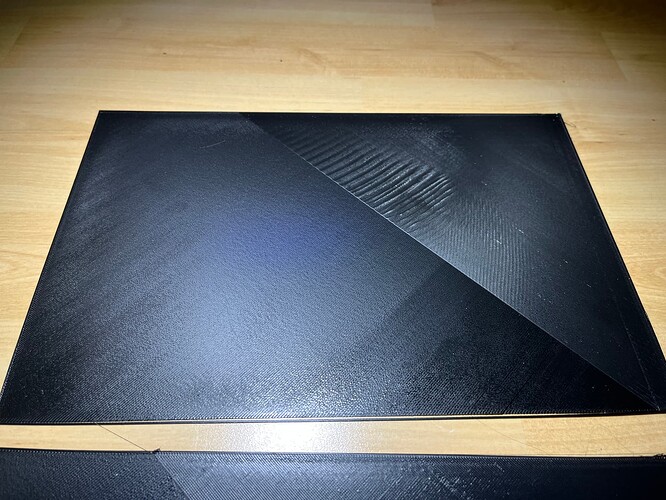

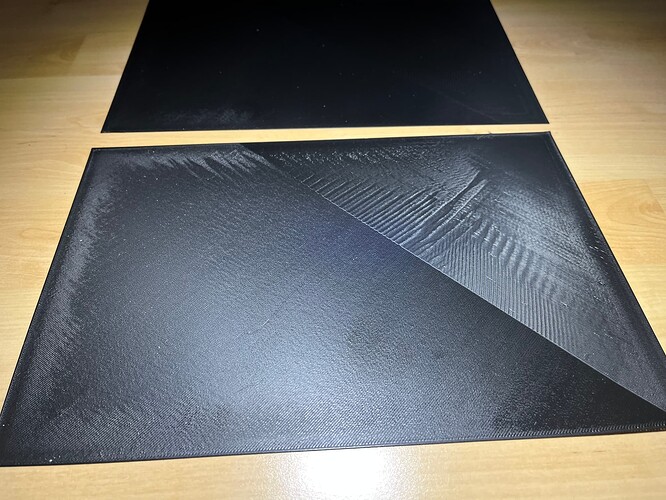

Unfortunately, this is difficult to see in the pictures; it is precisely this square tube that is causing me problems because it is too long.

And when I have all the screws in, it pushes the side guide about 0.4 mm to the right with tension.

Update:

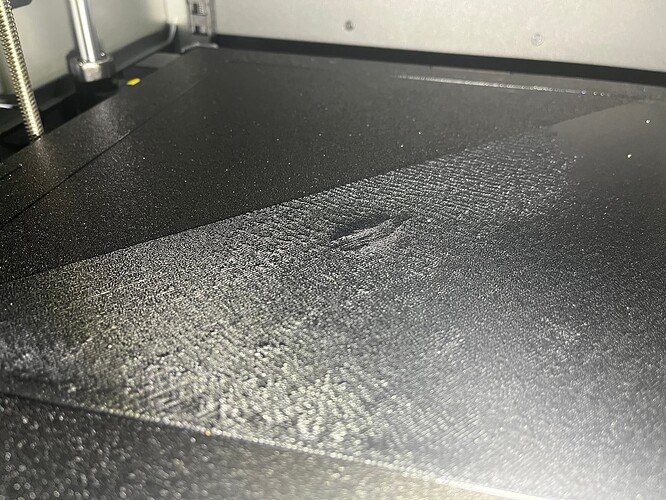

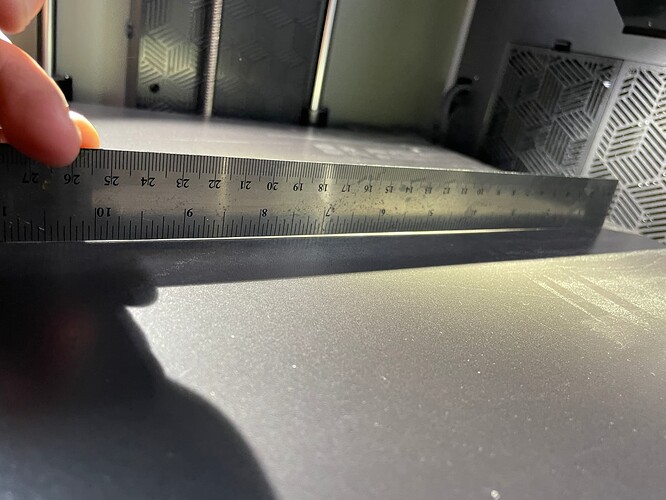

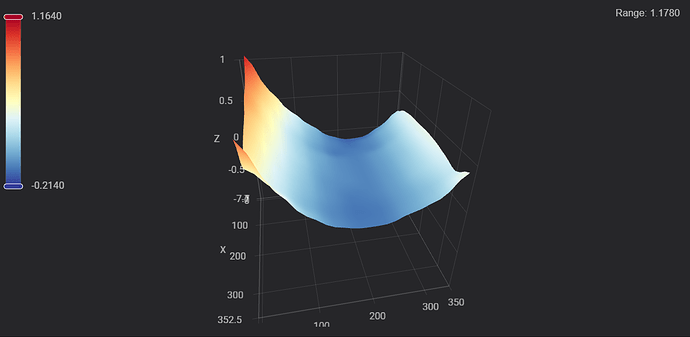

Small correction, it’s not the square tube after all, it looks like it’s the round bars that are under tension, i.e. bent, because if I push the X-carriage all the way back or forward, I have enough play to push the square tube back and forth and can screw it tight without tension, only towards the middle does it get tighter and is under tension.

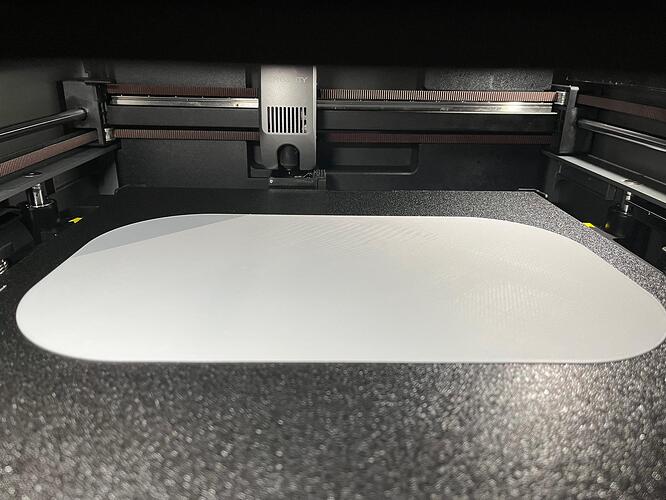

But to reinforce the theory again, I printed out a 300x300x0.2mm sheet and the problems start in the middle, I just wanted to clarify that again.