ABS is one of the first filament materials to be used in 3D printing. It enjoys enduring popularity for its low price and excellent mechanical properties, showing excellent toughness and impact resistance. As an amorphous plastic, ABS has a high glass transition temperature (glass transition temperature: glass transition temperature is an important physical property of amorphous polymers, and it is also an important problem and difficult problem in the basic theory of condensed matter physics. It is a relaxation phenomenon of the amorphous part of the high polymer from the frozen state to the thawed state), and the heated form also slowly changes from the outside to the inside, which means that ABS can withstand higher before completely losing its physical strength temperature. ABS is also one of the options for 3D printing consumables.

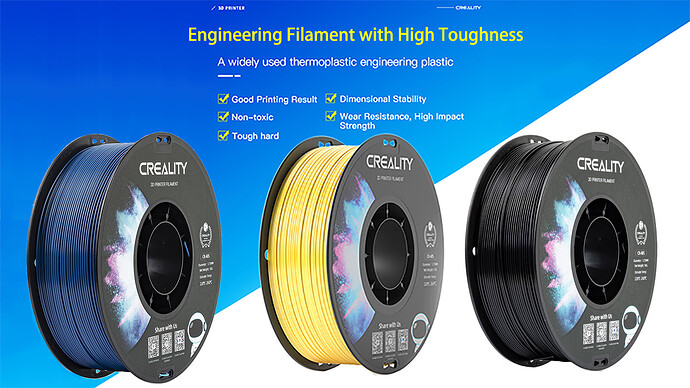

Advantages: lower cost, good strength and abrasion resistance, softness, good heat resistance, very fast printing speed.

Disadvantages: Higher printing temperature is required, the printing temperature of this material is 210~240°C, it deforms obviously after cooling, and the bed or heating chamber must be heated, which will produce unpleasant odor when heated, and the molding precision is poor.

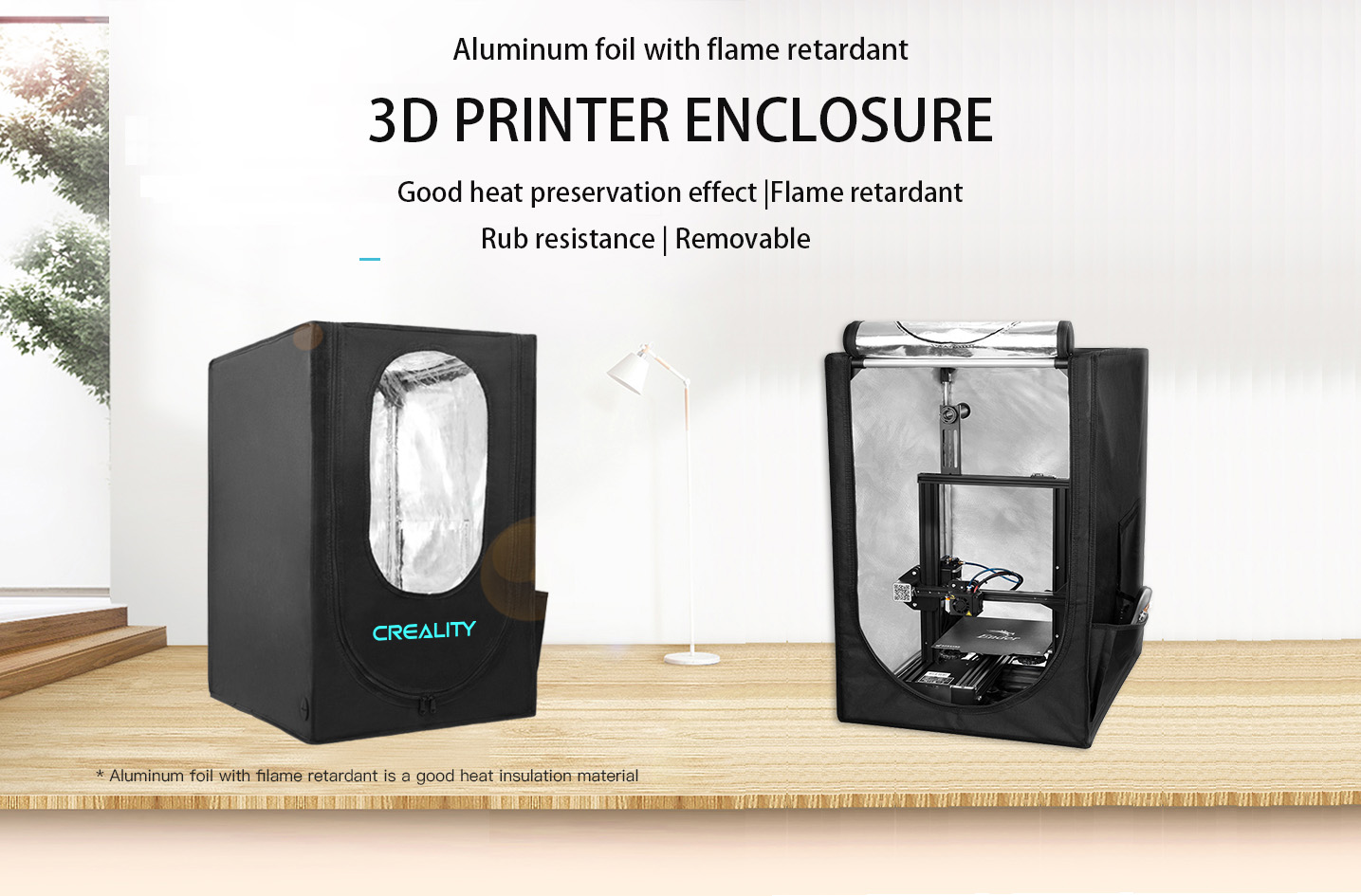

We are recommended to print ABS in closed printers or used it with Enclosures. Printer enclosures not only provide protection against dust and fire, but when printing high-temperature filaments, the enclosure maintains a constant high-temperature printing environment, unaffected by the ambient temperature, improving the success rate of model printing.

The following points must be kept in mind when 3D printing.

1. Control the warping

The most common problem with printing ABS is warping. ABS wire is extruded with a temperature of at least 220 degrees, and then immediately cools to ambient temperature. This large temperature change will cause the material to shrink. As a result, ① the first layer of wire is separated from the platform, and the common condition is warping, and ② the model will shrink to form deformation, such as the long side bending inward.

To reduce warpage, a higher temperature hot bed must be set and heated to 110C to improve warpage. In addition, in the slicing software, the function of printing the initial layer of temperature can be turned on, so that the nozzle and platform have a higher temperature when the initial layer is printed. When printing large parts, in order to reduce shrinkage, it is necessary to reduce the wall thickness and its filling within the effective range, that is, reduce the overall amount of model material to reduce the degree of shrinkage deformation. The use of windshield function, local temperature can be considered to avoid excessive cooling and large temperature change caused by ambient airflow during the printing process.

2. Slicing software settings or using adhesive

There are a variety of settings in the slicing software, which you can adjust according to your needs.

To prevent warping during printing, we can set the edge and support options in the slicing software before printing, which can provide additional surface contact between the part and the base plate to help the first layer of adhesion. In this case, if warping occurs, the edges or supports will be affected, but other parts will not.

Set the first layer height to 150% of the regular layer height, this way it increases the surface contact it makes, which is good for holding the model firmly in place.

Use adhesives: such as PVP solid glue, textured paper, anti-warping film, etc. The glue can bring good adhesion and can be directly applied to the hot bed platform, which has a good effect on anti-warping.

3. Ensure that the environment is suitable

To reduce the interference of ambient temperature and airflow to ABS printing, it is necessary to provide a stable environment for the printer as much as possible. A closed case and its constant heat unit is a great option. In addition, because printing with ABS will form a strong smell, which is harmful to the human body if inhaled for a long time, air circulation or air filtration must be done well, such as installing an air filtration system and exhausting the smoke outdoors.