Different filaments have different temperature requirements due to their varying chemical compositions. Each filament has a glass transition temperature and a melting temperature that determine its printing temperature range.

Filaments are typically printed just below their melting temperature to maintain extrusion control. Heating them beyond this point can lead to excessive flow and difficulties in handling.

Some filaments also require specific heated bed temperatures to minimize warping during cooling and improve adhesion to the bed.

Correct temperatures are crucial for successful printing. Let’s explore the best 3d printing temperatures for PLA, ABS, PETG, Nylon, and TPU filaments!

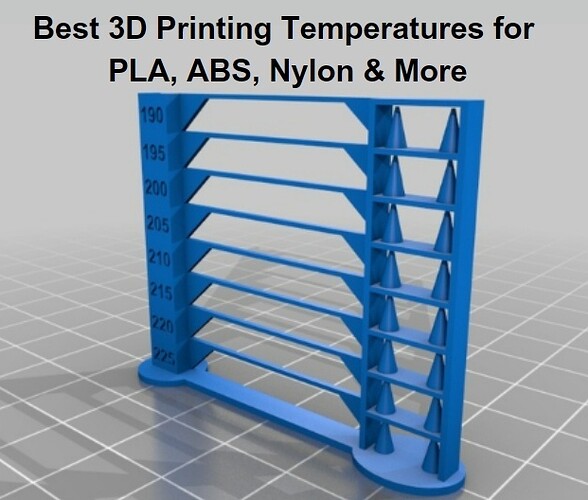

Best 3D Printer Filaments Temperature Chart

| Filament | Nozzle Temperature | Heatbed Temperature | Strength | Flexibility | Durability | Difficulty to Use | Shrinkage/Warping |

|---|---|---|---|---|---|---|---|

| PLA | 180-230 °C | 20-60 °C (optional) | Medium | Low | Medium | Low | Minimal |

| ABS | 210-250 °C | 90-110 °C | High | Medium | High | Medium | Considerable |

| PETG | 220-250 °C | 50-80 °C (optional) | High | Medium | High | Low | Minimal |

| Nylon | 240-290 °C | 55-65 °C | Very High | High | High | Medium | Considerable |

| TPU | 210-230 °C | 30-60 °C | Medium | Very High | Very High | Low | Minimal |

Best 3D Printing Temperatures for PLA

PLA is the most popular filament in consumer 3D printing today and dominates it. It’s popular for good reasons, such as flexibility in printing conditions, almost endless colors and styles, and the fact that PLA is, to some extent, more environmentally friendly than many 3D printer filaments.

PLA printing temperatures typically range from 180 to 220 °C. Some recommend starting around 200 °C and adjusting up or down as needed. It does not require a heated bed, but if your printer has one, set it between 20 and 60 °C. You can probably get up to 70 °C, but avoid higher temperatures. Because PLA tends to deform at temperatures of 60 °C or higher.

When printing with PLA, be sure to keep the cooling fan on. PLA produces the best results with proper cooling. Overall, PLA is easy to print and you don’t need much to be successful.

Note: The PLA is brittle compared to other types of 3D printer filaments, so avoid using it when making items like phone cases, high-wear toys, or tool handles.

Read more: Ideal PLA Bed and Nozzle Temperature Guidelines

Best 3D Printing Temperatures for ABS

Although ABS is not as popular as PLA in daily 3D printing, it is still the most widely used filament.

Products made of ABS offer high durability and the ability to withstand high temperatures, setting the nozzle temperature between 210 and 250 °C during the printing process. A heated bed is also needed. If possible, target a temperature of around 110 °C. If your printer cannot reach this temperature, 90 °C is sufficient. 3D printer enthusiasts should therefore be aware of the filament’s high printing temperatures, tendency to deform during cooling, and strong, potentially dangerous fumes.

Note: The ABS needs to be printed in a closed 3D printer so that it cools very slowly. ABS shrinks as it cools, and if the print cools too quickly, it will warp. For the same reason, the cooling fan should be turned off when printing ABS.

Read more: Advantages and disadvantages of ABS filament in 3D printing and how to use it properly

Best 3D Printing Temperatures for TPEG

PETG is a combination of PLA and ABS, which is more flexible and durable than PLA, and easier to print than ABS.

It requires very high temperatures, with nozzle temperatures between 220 and 250 °C. However, unlike ABS, PETG does not require a heated bed.

Notes:

-

PETG is highly “hygroscopic”, so be sure to store 3D printer filaments in a cool, dry place and, if necessary, dry them before use.

-

PETG is sticky when printed, so this 3D printer filament is not a good choice for support structures, but it is a good choice for layer bonding.

-

PETG is not brittle, but tends to scratch more easily than ABS.

Best 3D Printing Temperatures for Nylon

Valued for its exceptional strength, flexibility, and durability, nylon is a preferred choice for producing robust tooling, functional prototypes, and mechanical components such as hinges, buckles, and gears.

Nylon is distinguished from PLA, ABS, PETG and other filaments by its higher print temperature, typically requiring a range of 240 to 290°C. Using a 3D printer equipped with an all-metal hot end capable of withstanding elevated temperatures is essential for successful nylon printing. Maintaining a bed temperature between 55 and 65°C is recommended, with the added precaution of applying a layer of adhesive to improve bed adhesion and counteract nylon’s tendency to inadequately bond.

Notes:

-

Nylon should not be printed with cooling fans as it needs to retain heat for proper layer adhesion.

-

Nylon is hygroscopic like PETG, so it needs to be stored in a cool and dry place to keep the filament in optimal condition to ensure better printing quality, or the filament needs to be dried before printing.

Best 3D Printing Temperatures for TPU

TPU is a very flexible material and is often used to print parts that require bending, stretching or compression, such as toys, phone cases or wearable devices (such as wristbands).

TPU prints at temperatures similar to PLA, with optimal operating temperatures around 210 to 230°C and bed temperatures of 30 to 60°C.

Notes:

-

Due to the flexibility of TPU, it can bend and stretch on its way from the extruder gear to the actual nozzle. Therefore, it is important that the filament follows a limited path and extrudes slowly without retracting.

-

The extruder temperature can be increased slightly to reduce the stress on the filament that may cause it to bend.

Read more: Comparing Creality 3D Printing Materials: A Comprehensive Guide