In recent years, 3D Printing has emerged as a transformative technology, reshaping the landscape of manufacturing, prototyping, and creative expression. This revolutionary method, also known as additive manufacturing, involves building three-dimensional objects layer by layer from digital models.

As the popularity of 3D Printing continues to soar, enthusiasts and professionals alike are delving into the intricacies of the process to unlock its full potential.

- The Significance of Precise Temperature Control in 3D Printing

- The Significance of Temperature in 3D Printing

- Overview of the Two Crucial Temperature Parameters

- PLA Bed Temperature Guidelines

- PLA Nozzle Temperature Guidelines

- Optimal PLA Nozzle Temperature for Various Print Settings

- Balancing Nozzle Temperature for Print Speed and Quality

- Step-by-Step Guide on Setting and Maintaining Ideal PLA Bed Temperature

- Tips for Achieving Consistent PLA Bed Temperature Throughout the Printing Process

The Significance of Precise Temperature Control in 3D Printing

Successful 3D Printing depends on a critical factor called precise temperature control. The relationship between temperature and print quality is complex, impacting various aspects of the printing process. From reducing warping and improving layer adhesion to ensuring proper print bed adhesion, maintaining optimal temperatures is key to achieving impeccable results.

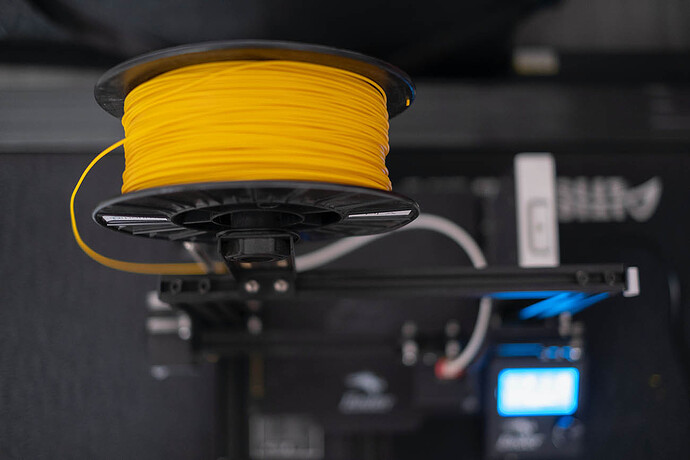

1. PLA Filament

Among all the materials available for 3D Printing, Polylactic Acid (PLA) filament stands out as a popular and versatile choice. PLA is a biodegradable thermoplastic derived from renewable resources, such as corn starch or sugarcane. Its eco-friendly nature, coupled with low odour during Printing, has contributed to its widespread use in various applications.

2. The Widespread Use of PLA in 3D Printing

PLA has become the go-to filament for many 3D printing enthusiasts and professionals. Its ease of use, vibrant colour options, and affordability make it an attractive choice for a wide range of applications, including prototyping, hobbyist projects, and educational purposes. The biodegradability of PLA further adds to its appeal, aligning with the growing emphasis on sustainable and eco-friendly manufacturing practices.

In this blog, we will delve into the critical role of temperature control in PLA 3D printing, focusing on both bed and nozzle temperature guidelines. Understanding and mastering these temperature parameters will empower 3D printing enthusiasts to unlock the full potential of PLA filament and elevate the quality of their prints to new heights.

The Significance of Temperature in 3D Printing

The temperature at which a 3D printer operates significantly influences the quality and structural integrity of the printed objects. Precise temperature control is crucial for achieving the desired outcome in terms of surface finish, layer bonding, and overall print accuracy. Variations from optimal temperature settings can lead to a range of issues, affecting the visual appeal and mechanical properties of the printed object.

The Role of Temperature in Minimizing Warping, Layer Adhesion, and Print Bed Adhesion

Warping

Warping is a common challenge in 3D Printing, especially with materials like PLA. This phenomenon occurs when there is a temperature differential between layers, causing the material to contract unevenly. By maintaining a consistent and appropriate temperature, particularly in the initial layers, the risk of warping is significantly reduced.

Layer Adhesion

Layer adhesion is vital for creating robust and durable prints. Proper temperature control ensures that each layer bonds effectively with the previous one, resulting in a structurally sound object. Inadequate temperature can lead to weak bonds between layers, compromising the overall strength and integrity of the print.

Print Bed Adhesion

Achieving proper adhesion to the print bed is crucial for preventing print failures. The initial layers of a 3D print are foundational, and the bed temperature plays a pivotal role in ensuring these layers adhere securely. Optimal bed temperature contributes to better adhesion, reducing the likelihood of prints detaching or warping during the printing process.

Overview of the Two Crucial Temperature Parameters

Bed Temperature

The PLA bed temperature, also known as the build plate temperature, directly influences the lower layers of the print. This temperature is critical for preventing warping and ensuring adhesion to the print bed. Different materials may require different bed temperatures, and finding the right balance is essential for successful 3D prints.

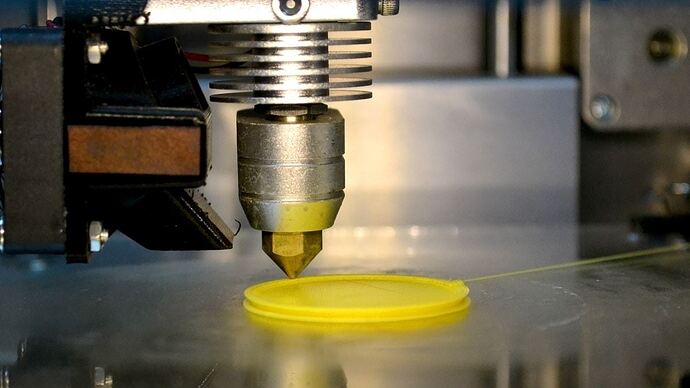

Nozzle Temperature

The PLA nozzle temperature refers to the temperature of the extruder’s nozzle through which the filament is melted and deposited layer by layer. It affects the viscosity and flow characteristics of the filament. Controlling the nozzle temperature is essential for preventing issues like under extrusion and clogs and ensuring consistent material deposition throughout the print.

PLA Bed Temperature Guidelines

Achieving the right bed temperature is a critical factor in the successful 3D Printing of PLA. The bed temperature directly impacts the initial layers of the print, influencing adhesion and minimizing the risk of warping. Maintaining an optimal bed temperature creates a stable foundation, ensuring that each layer adheres securely to the previous one, contributing to the overall structural integrity of the print.

Factors Influencing PLA Bed Temperature

Several factors come into play when determining the ideal bed temperature for PLA printing:

Filament Type

Different PLA filaments may have varying temperature requirements. It’s essential to refer to the manufacturer’s recommendations to understand the specific temperature range for the PLA filament being used.

Print Speed

The speed at which the 3D printer extrudes the PLA filament can impact the required bed temperature. Higher print speeds may necessitate a slightly higher bed temperature to ensure proper adhesion.

Layer Height

The layer height chosen for a print can influence the bed temperature. Experimenting with different layer heights and adjusting the bed temperature accordingly allows users to find the optimal settings for their specific print.

Print Bed Material

The type of material used for the print bed also plays a role. For instance, glass beds may require different temperature settings compared to build surfaces with specialized coatings like BuildTak.

Recommended PLA Bed Temperature Range for Different 3D Printers

While the specific bed temperature for PLA can vary based on the factors mentioned above, there are general guidelines that can serve as a starting point. It’s crucial to consult the user manual of the 3D printer and the recommendations provided by the filament manufacturer. In many cases, a bed temperature range of 60-70°C is suitable for PLA printing.

Correlation Between Bed Temperature and Adhesion

The correlation between bed temperature and adhesion is fundamental to the success of PLA prints. Adequate bed temperature ensures that the first layers adhere firmly to the print bed, preventing issues like peeling or detaching during the printing process. However, it’s essential to strike a balance – excessive bed temperature can lead to challenges in removing the printed object, while insufficient temperature can result in poor adhesion.

Experimentation and calibration are key components of finding the optimal bed temperature for PLA printing. Conducting test prints with incremental changes in bed temperature allows users to observe the impact on adhesion and make informed adjustments.

PLA Nozzle Temperature Guidelines

The nozzle temperature plays a pivotal role in PLA printing as it directly influences the state of the filament as it’s extruded layer by layer. Maintaining the correct nozzle temperature is crucial for achieving optimal PLA extrusion, preventing issues like under extrusion and clogs, and ensuring uniform layer deposition. The right nozzle temperature contributes to the overall print quality, surface finish, and structural integrity of the final object.

Factors Affecting PLA Nozzle Temperature

Several factors influence the optimal nozzle temperature for PLA printing:

Filament Type

Different PLA filaments have different temperature requirements. Variations in additives, colours, and manufacturing processes can impact the melting characteristics of the filament.

Print Speed

The speed at which the printer extrudes the filament affects the required nozzle temperature. Higher print speeds may necessitate a higher nozzle temperature to ensure consistent and smooth extrusion.

Layer Height

The chosen layer height can influence the nozzle temperature. Experimenting with different layer heights and adjusting the nozzle temperature accordingly allows users to find the optimal settings for their specific print.

Print Bed Temperature

The temperature of the print bed can indirectly affect the nozzle temperature. A well-calibrated balance between bed and nozzle temperature is essential for preventing issues like warping and ensuring proper adhesion.

Optimal PLA Nozzle Temperature for Various Print Settings

While the ideal nozzle temperature can vary based on the factors mentioned above, there are general guidelines that serve as a starting point for achieving optimal PLA extrusion. A nozzle temperature range of 190-220°C is commonly recommended for PLA printing. However, it’s essential to consider the specific requirements of the print and make adjustments accordingly.

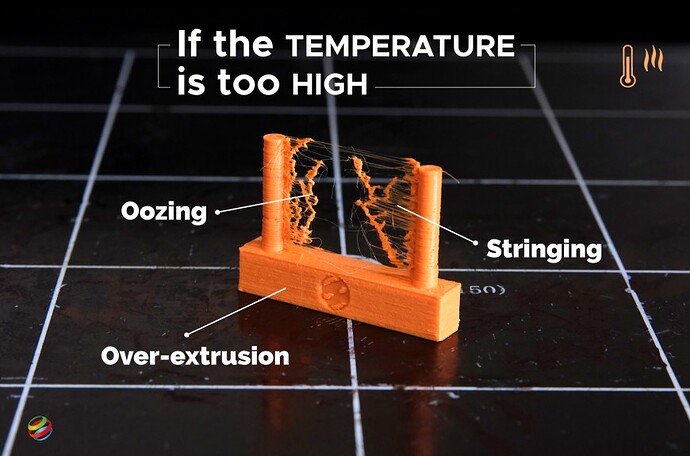

Lower Temperatures (190-200°C)

- Ideal for prints with intricate details.

- It helps prevent issues like stringing and oozing.

- Suitable for slower print speeds.

Mid-range Temperatures (200-210°C)

- A versatile range that is suitable for a variety of print settings.

- Balanced for quality and speed.

Higher Temperatures (210-220°C)

- Recommended for faster print speeds.

- Ensures proper flow of filament in high-speed prints.

- Suitable for prints where layer adhesion is crucial.

Balancing Nozzle Temperature for Print Speed and Quality

Balancing nozzle temperature is a delicate process that involves finding the right compromise between print speed and print quality.

Print Speed

- Higher nozzle temperatures are often required for faster print speeds.

- Adjust the nozzle temperature incrementally when experimenting with different print speeds.

Print Quality

- Lower nozzle temperatures are ideal for prints where fine details and precision are crucial.

- Experiment with lower temperatures to minimize stringing and improve surface finish.

Finding the optimal balance involves iterative testing and adjustments. Consider conducting temperature towers, calibration cubes, or small test prints to fine-tune the nozzle temperature for specific print requirements.

Step-by-Step Guide on Setting and Maintaining Ideal PLA Bed Temperature

Achieving and maintaining the ideal bed temperature is crucial for successful PLA 3D printing.

Calibration

Start by calibrating your 3D printer’s bed temperature settings. Refer to the printer’s manual for instructions on bed temperature calibration.

Preheating

Allow the bed to preheat before initiating a print. This ensures that the entire bed reaches the desired temperature, promoting consistent adhesion.

Bed Surface

Choose an appropriate bed surface for PLA printing. Materials like glass or BuildTak provide a smooth surface for adhesion. Ensure the bed is clean and free of debris before printing.

Print Bed Leveling

Ensure that the print bed is levelled correctly. A level bed contributes to even heat distribution and consistent adhesion.

Initial Layer Calibration

Perform initial layer calibration to fine-tune the distance between the nozzle and the bed. Proper initial layer calibration enhances bed adhesion and prevents issues like uneven first layers.

Temperature Testing

Conduct temperature testing by printing small test objects with varying bed temperatures. Analyze the results to identify the temperature that provides optimal adhesion without excessive difficulty in removing the print.

Tips for Achieving Consistent PLA Bed Temperature Throughout the Printing Process

Enclosure

Consider enclosing the 3D printer to maintain a stable ambient temperature. This is particularly beneficial in drafty environments where temperature fluctuations can impact bed adhesion.

Insulation

Insulate the print bed if possible. This helps in minimizing heat loss to the surroundings, ensuring a more consistent bed temperature.

PID Tuning

Perform PID tuning on your 3D printer. Proportional-integral-derivative (PID) tuning optimizes the temperature control loop, enhancing the stability and accuracy of the bed temperature.

Thermal Imaging

Use a thermal imaging camera to inspect the bed temperature during printing visually. This allows you to identify any hotspots or uneven temperature distribution.

Fan Control

If your 3D printer has a heated bed with a fan, consider controlling the fan speed to regulate temperature. Adjusting the fan can help maintain a consistent temperature, especially during longer prints.

Conclusion

Mastering PLA bed and nozzle temperatures is essential for unlocking the full potential of 3D printing and achieving high-quality prints. Both bed and nozzle temperatures significantly influence the overall print quality and structural integrity of 3D prints. Maintaining precise temperature control results in the production of visually appealing and robust objects.

The correlation between bed temperature and adhesion, coupled with the importance of nozzle temperature in ensuring smooth extrusion, underscores the critical role these temperature parameters play in the success of PLA printing.

We encourage you to try experimentation and fine-tuning temperature settings. Each 3D printer, filament, and print project have unique requirements. Through trial and error, you can discover the optimal combination of bed and nozzle temperatures that align with your specific needs and preferences.

The field of 3D printing is continually evolving, with advancements in technology, materials, and techniques pushing the boundaries of what is possible. Temperature control remains at the forefront of these advancements, enabling users to explore new horizons in 3D printing. In this dynamic landscape, Creality’s printers offer a reliable and innovative solution for 3D printing enthusiasts. Utilizing Creality’s printers provides a solid foundation for implementing the temperature guideline as its user-friendly interfaces, coupled with advanced features, empower users to delve into the art and science of 3D printing with confidence.