My Experience with the Ender3V3KE

I am new to the world of 3d printing and I purchased this KE printer on a pretty good deal over the 4th of July holiday. But I have to say it has not really been a pleasant experience and I do have until Aug 7th to return the whole shebang and call it good before I loose any more money or expend any more frustration.

It was a refurbish unit a that is fine purchased lots of items refurbished. I have a Brother MFC laser printer I purchased over 10 years ago and it’s still working great. But this printer has been a challenge right out of the box.

First things first, the gantry upright screws are woefully too short to begin with at 3mm x 14mm, but since this unit had previously been assembled the threads were already comprised and I replaced with 3 x 20mm and will probably still yet go to 25mm.

Several of the brass pem nuts were partially pulled out above the plastic, I was able to push this back down, but once these are compromised they really do not have any holding strength.

Also the nozzle was completely clogged from the previous user so I used the ‘spare’ included in the kit.

Basically someone returned this printer, Creality opened the box, said looks ok and tossed in a new hardware and tool kit and taped it back up and sent it out.

Ok so I get it up and running and get the firmware update and I print a few things, some nicer then others, I open up and try a few different filaments, all factory Creality PLA so I can expect the best experience.

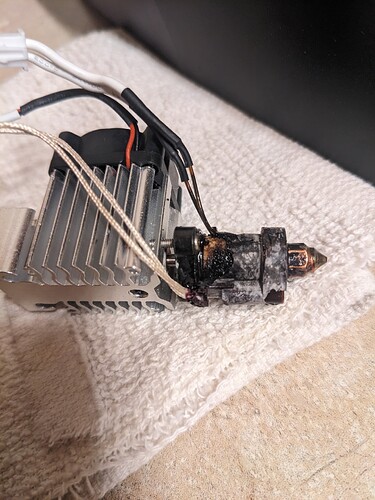

Then after about say maybe 10 small prints, cubes, cones, cups, heart, figurine, etc I start having issues. The nozzle starts dragging across the bed, hot plastic forces up out the top of the nozzle, start getting bubbles and strings on everything. Also starting to get error messages on the printer screen. WTH?

So what the hell has happened here?

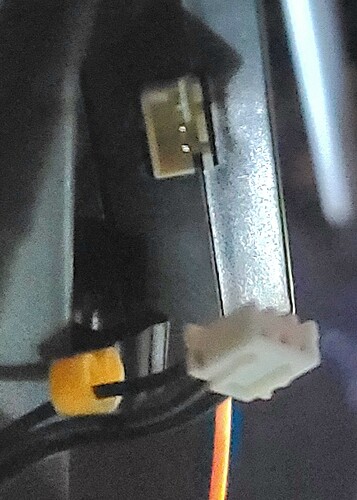

I start by using a pick to pull loose the glue holding the connectors before carefully disconnecting and start pulling things apart to inspect things, I find a wire has come loose or was never fully seated in one of the CR Touch connectors.

So I send an explanation and proof of purchase to our good friends at Creality and without question they are sending me a new wire harness for the CR Touch sensor, new hot end assembly, new .04 brass nozzle and a new build plate. Sweet, thanks! The representative also asks me to be patient, that’s fine I appreciate the quick reply and no questions asked hook up. I assume this is coming from China and will take a few weeks, no biggie.

I had included my home address to ship to since I no longer have access to the address I originally had the printer shipped to (old job). So in like 2 days I get a email from DHL that the package is on its way and due to be delivered in like a day to the original shipping address…Ugh! No biggie, I am able to append the address and it will cause a one day delay, again no biggie as I was expecting weeks.

Here I would like to give a huge thanks to Creality for their quick service and no questions asked warranty replacement parts. Thank You ![]()

I had already purchased a replacement hot end so I could get the printer back up and running, that arrived today. Also a upgraded Micro-Swiss heatsink which is pretty nice over the original unit.

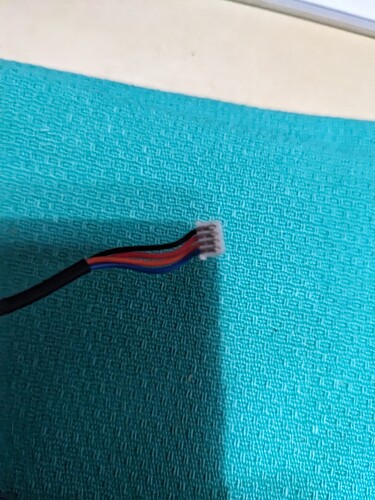

In the meantime when I was taking apart the hot end assembly and unplugging the extruder, the wire connector for the extruder breaks apart in my hand, Faak!

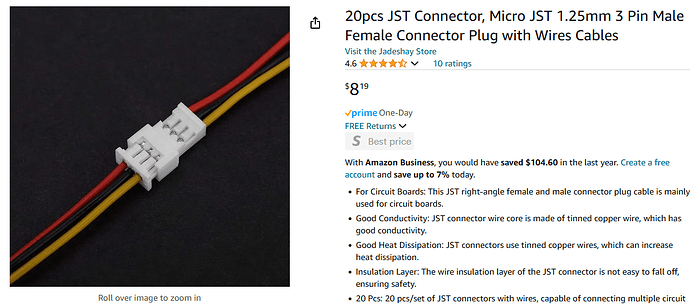

Ok no biggie, I do some research online and from prior experience in small form factor electronics and some measurements I determine the connector to be a JST ZH connector so I jump on Digikey and figure I am going to be modding this thing and plugging things in and out and will most likely run into this again.

So I order 100 connectors and 25 each of 2, 3, 4, and 5 pin housings, that only added up to about $7 and I kind of need these parts quickly so I opt for the 2 day priority shipping for $12 so after tax there’s another $20 out of pocket, no biggie.

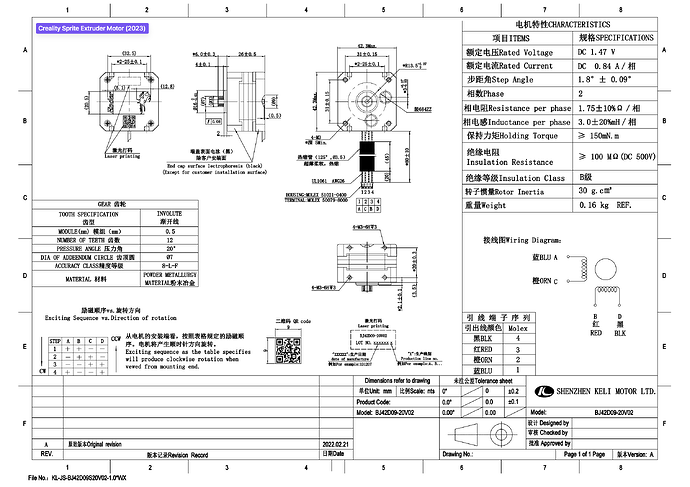

Tonight I start looking real close at the connectors again, despite taking my time before ordering and I now realize the connectors are Molex Pico Blade and are not cross compatible with the JST ZH connectors, Great, more delays, more money.

Made that order and the original Molex pico blade connectors are significantly more expensive than the JST ZH connectors. I have a sneaking suspicion that the ones used on the printer are probably homeland clones and not the original oem parts.

I wanted to dip my feet into the water and see what it was all about, and well now I know. I am already frustrated on the hobby and not even 1 month into it… ![]()

Alright, thanks for letting me vent, we all know these are entry level machines and we should be prepared to invest some sweat equity into the project. I will post up information on how to make the wire end repairs with part numbers as I think that will be beneficial to the community.