Honestly, it has been a mixed bag.

The hardware setup following the video from Creality Support channel (https://www.youtube.com/watch?v=F4hk6RIgWXQ) (or the same included setup manual) is fine - except it ends just before the trouble starts.

Initial setup was a pain due to confusing instructions and firmware issues. Over time some things have become out of date but gets looked as the info is sparse at the moment. Part of the issue is that you run into things that look different from what you see sampled. The Co Print channel video for instance is out of date - see its comments about config files being different. Also the official Wiki page from CoPrint does the same. Follow the hardware steps and then just guess.

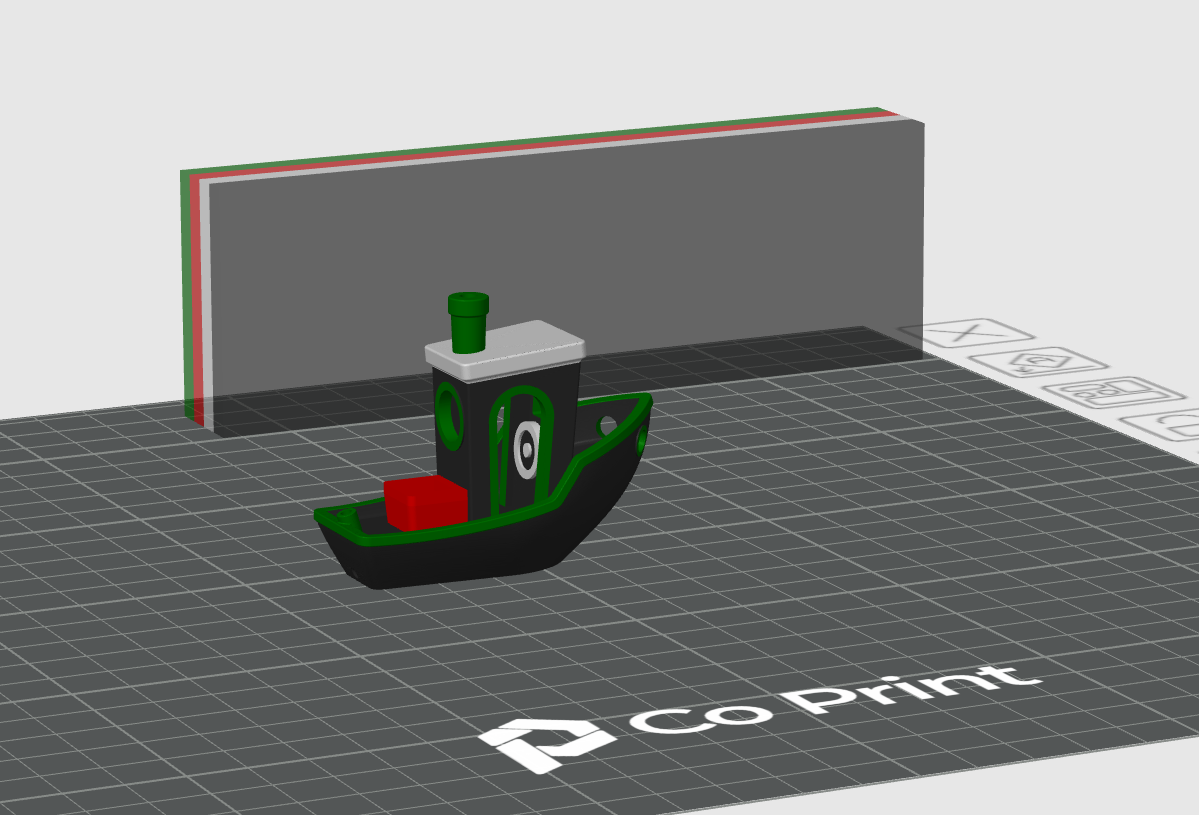

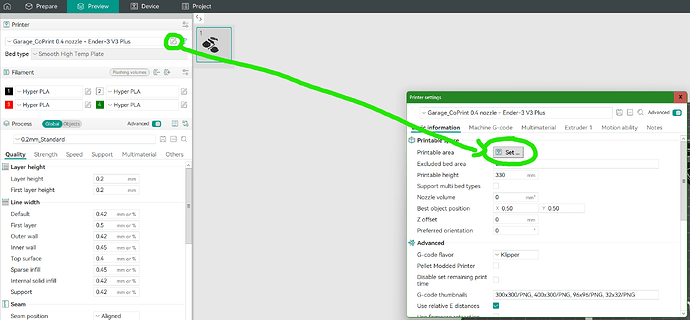

After the hardware setup the next instruction is to use the USB drive to update firmware to some older version. My first firmware update failed when using the USB drive (but might not for anybody else). I finally got the latest firmware (1.2.3.63 as at todays date) from that CoPrint wiki page link specifically dealing with the V3 (Ender 3v3 KCM Set Setup Page | Co Print Wiki). That got the printer up and running and then I copied the config files for 8 colour (in my case) also from that Wiki page link. At this point I was able to print as usual from both Creality Print and Orca slicer, knowing that it will have an incorrect build plate size (turns out is becomes 290x283 for the V3 Plus, (minus what the purge tower will if doing multicolor).

At this point I had ended up in the general Kcm setup page of the Co Print wiki and I thought I would make the config changes described there but got completely lost as my system files looked different and as I don’t know mainsail I could not even find my printer menu items etc. trying to use standard V3 Plus interface. I ended up making my printer unusable and had to restore the firmware to factory settings (basically restoring the newly installed firmware to be what I had just a little earlier after first installing it). So I left out the config changes alone at that point.

I had Orca slicer 2.2 and it had a profile for CoPrint Chromahead, but only PLA filament. I downloaded Orca 2.3 and at least it had 4 machine profiles and the PLA profile (very limited).

I was able to print a colour change model from Orca slicer right then. I copied the profile data to Creality Print - basically build plate size and including extruder number variables for machine G-code ‘start print’ and ‘filament change’.

Trying to print with Creality Print gives all kinds of issues though like losing connection to the print head mid print, nozzle staying on the print model while changing filament, which the Orca slicer gcode does not do - it always parks in the purge tower. Also found with Creality print it would just stop extruding close to the end of the print. So I will not use Creality Print for now - even though it appears the settings are all the same as my Orca setup.

Speed and print quality is just as good as standard V3 plus except it might be slightly weaker with the cooling but I have not been able to test and tune enough yet to say for sure.

I have not tried TPU yet, only PLA, silk and PETG. All print fine - extrusion is consistent.

So effectively all I needed to have done (which took close to 3 days) was :

- Build hardware

- Install firmware 1.2.3.63 and load 8 colour config files (not edit them too)

- Install/Update Orca Slicer 2.3

(I did design and print a model for installing the control boxes on top - my lightbar fittings got in the way and it seemed the homing of this printer (no longer limited to x=0 axis, could rip it off the top but that is personal taste mostly)

In all this testing and not knowing exactly what I used and in getting the know how things work I have ended up with some frustrations as often error messages on screen have no way to cancel them - turning off the machine is the only way. I must say though that it might be Creality Print - it seems to cause issues with commands that somehow the printer cannot handle. I finished a comparison of the same print today 2hrs each time, one with Orca which went flawlessly and was beautiful, and one with Creality Print which was just weird and ended up doing some things I have never seen before since my first Anycubic mega pro and a dodgy build plate heater and extruder (ended up being fantastic eventually).

I am now finishing an 8 hour multicolour PLS Silk print which looks very good and has no issues up to this point.

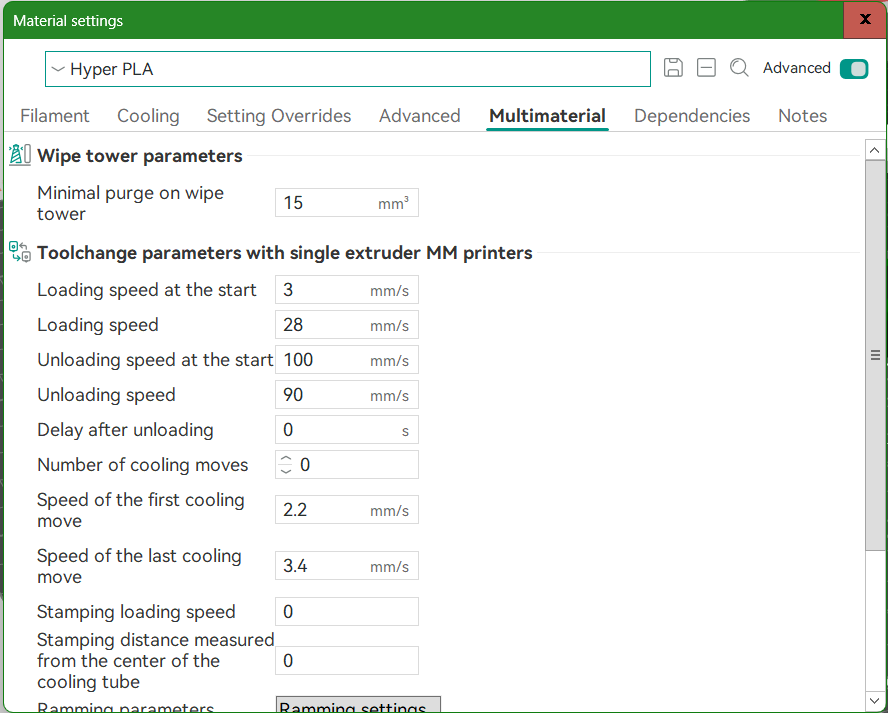

Also, I found you can set up filaments in multiple slots and use only number 3 and 4 for instance. It’s not like you have to start with extruder 1. There does not appear to be a way to map a colour in your slicer to a filament extruder in the printer, i.e. 1 is 1, 2 is 2 and so on. The tuning of the flushing volumes are also still a mystery, and so far my testing has taught me I need to waste more filament…(sigh)

One word of advice initially is to retract and extrude each filament you are about to use in your print before you start - just to make sure all the path ways are clear.

All in all I was very dissatisfied for a few days and had a few choice words I wanted to aim at Co Print - but now I am much more confident, using Orca mind you, that my prints will work. No issues at all with single colour prints.

A few issues to work through still - I have gotten into the habit of setting a lower speed than I intend print at in my slicer for certain prints with smaller footprints or when I am not sure how well a filament will perform for the model. I then speed it up on the printer screen or slicer monitoring interface if all goes well to save time - but I have found with multicolour here the speed adjustment gets reset each layer when doing the purge tower. Not sure why because on my A1 it keeps my adjustments - but I have not read up on that yet.

Now I have used my 1 000 words for this year so I am signing off.