We managed to do it by first installing only the firmware, the latest one, and then using it with the Orca slicer. After selecting the appropriate printer in Orca, it worked almost flawlessly. There may be errors with Creality print.

I am using Orca Slicer as well, but the issue is before using any slicer software, it is about the firmware booting up. ![]()

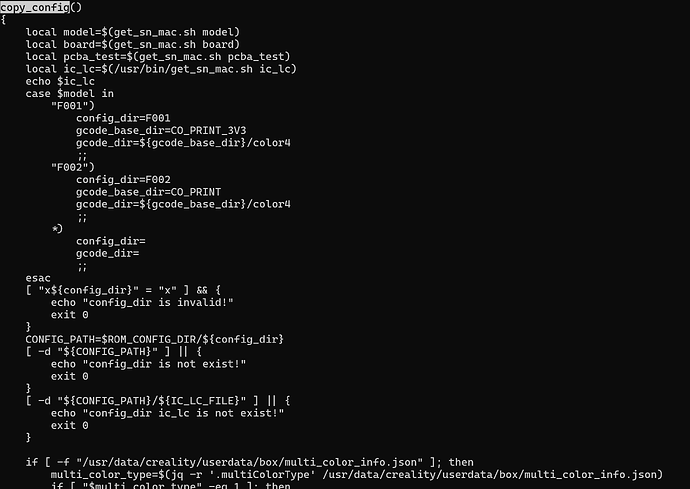

Are you using 4 colors or 8 colors, I have not thought it through but there is some code path that seems to be using the /usr/share/klipper/config/F002/color8 as the fundation of copy_config stuff.

I currently use 4 colors, but I ordered the +4 color ECM set. However, if you have an 8 color set, then the original Creality head cable with the splitter is probably not enough to power it.

In principle, changing from 4 colors to 8 colors will only be a matter of selecting level 8 instead of 4 on the printer display after assembly. But when it arrives, it will turn out that this is the case. However, the USB hub will play a role here, I spoke to Coprint before ordering, and they also said that only one that can provide adequate bandwidth and power supply will be good.

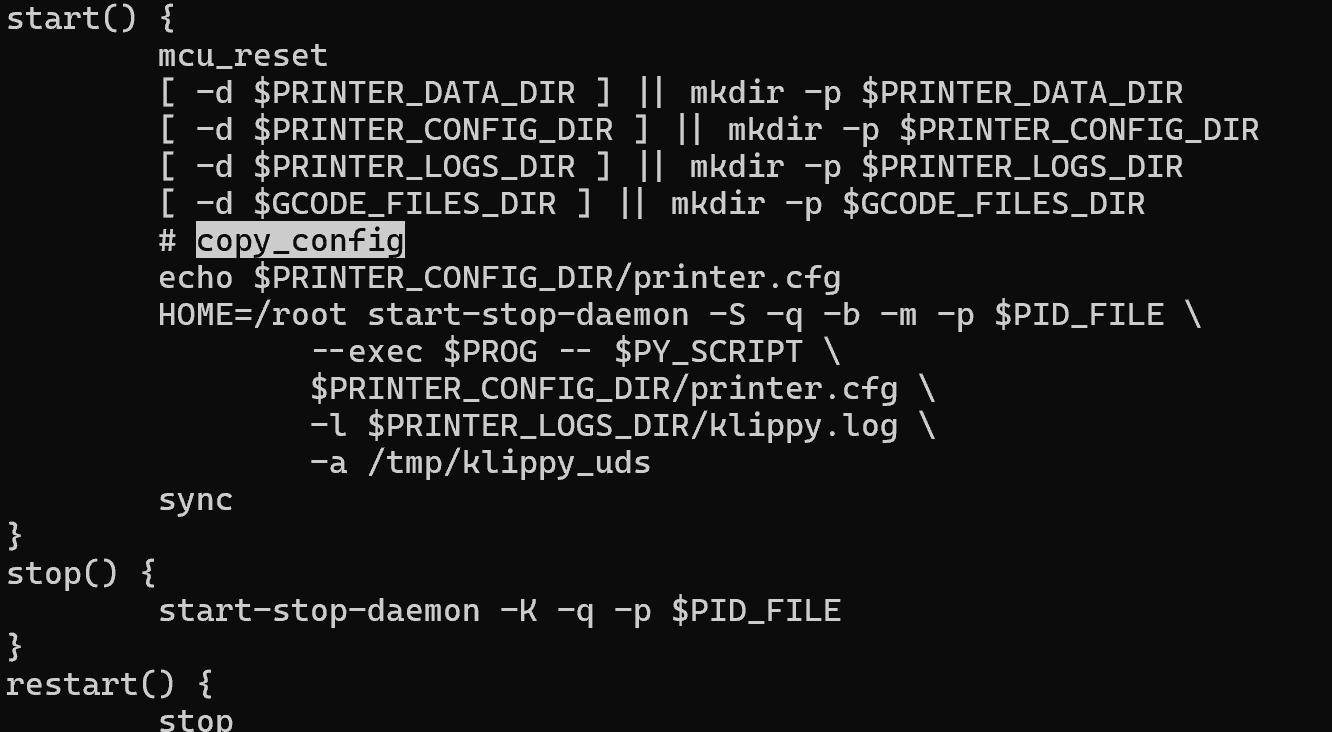

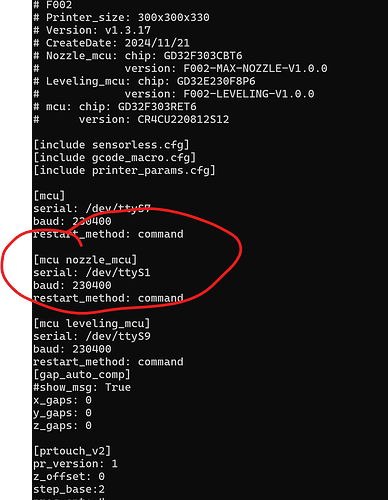

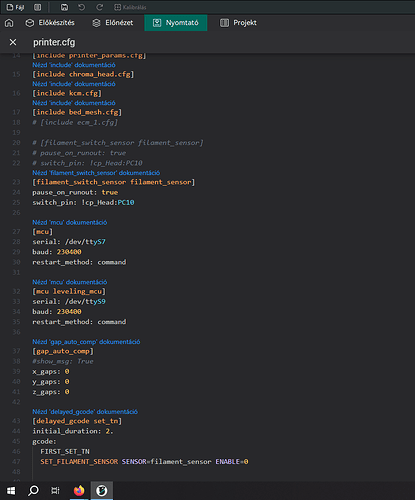

No. I tried without the USB hub it doesn’t make any difference. And from the code and config I can see that the original config should not work, because it contains the original “nozzle mcu” which would be disappeared after switching to the coprint set. And it is exactly what it was complaining, cannot talk to the nozzle mcu. Commenting that part out from the config file solves the issue. How the original config file works for you guys is the part that confuses me ![]()

Could you take a picture of the code in question?

I would like to look at my own config files for comparison. I would be curious to know if there is a difference.

I think it must contain the original head codes, because the firmware must be installed with the original head, in an unopened state. Although I haven’t tried it, I have a feeling that if I hadn’t switched to the Coprint set after the firmware update, it would still have worked with one color, with the original head.

Is the correct coprint printer selected in Orca?

I think you should talk to the Coprint team, they may be able to help you online, for example via teamviewer. This is how many people have solved the problem.

You can also ask your question on Discord.

After working around my SW issue. Now I have some other questions that hope to get some help. ![]()

- Where the end of PTFE meets the 8-in-1 seems to be very likely creating a bottleneck for the filament. I have seen it several times that the filament got stuck there during color change. When that happens, if I pull out the filament and manually extrude it, I can feel that there is a difficult point to pass. Any trick on how to install the PTFE to be really flush with the 8-in-1?

- The blocking clip for that PTFE, it is really hard to push in. Any trick on install that?I suspect that my problem in #1 is related to whether I have installed the blocking clip correctly? I have always tried to retract/extrude the filament before printing, but it seems the PTFE got moved during printing so #1 happened?

- I used a smart plug to monitor the power usage. When printer powered up, it takes around 13W idling. During printing it takes ~100W. Those are reasonable. But the problem is that after printing, the printer keeps taking ~50W forever. So I guess something used during printing never gets turned OFF after printing?

Update on those:

for #1, #2, it seem that the issue was caused by the stopping clip not installed correctly. I still cannot fully push the clip in, most of the times the C shaped clip can only get one leg under the PTFE holder cap. But if I carefully align it, to make sure the leg under the cap is on the side that the tube tend to lean to, it does make things a lot better.

For #3, I still need to do more experiment to confirm, but so far looks like it is caused by the motor not set to OFF after printing. It is surprising that it take ~40W for that, though.

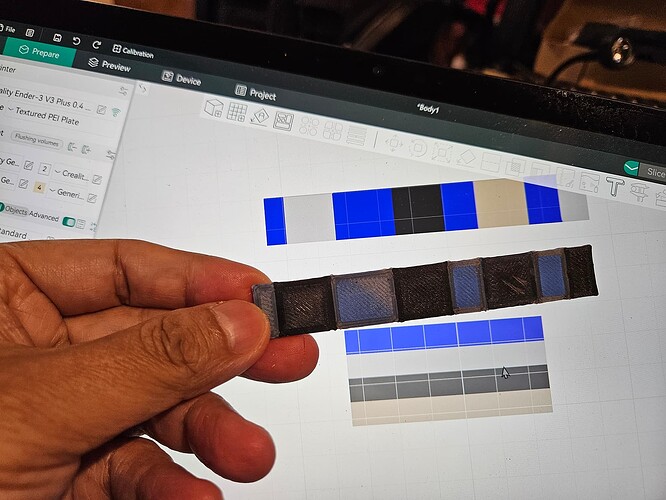

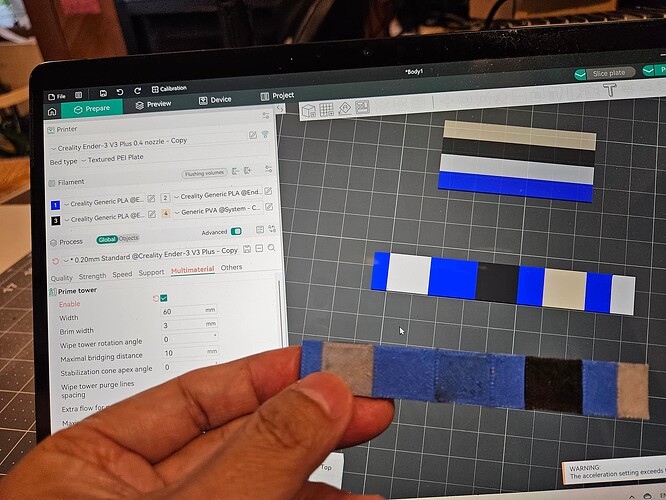

I still have not totally figure out the multi color printing in Orca Slicer yet. I thought my settings were correct, but the result does not look like what I would expected. ![]()

Hi!

I checked, yes, mine is like the improvement with you.

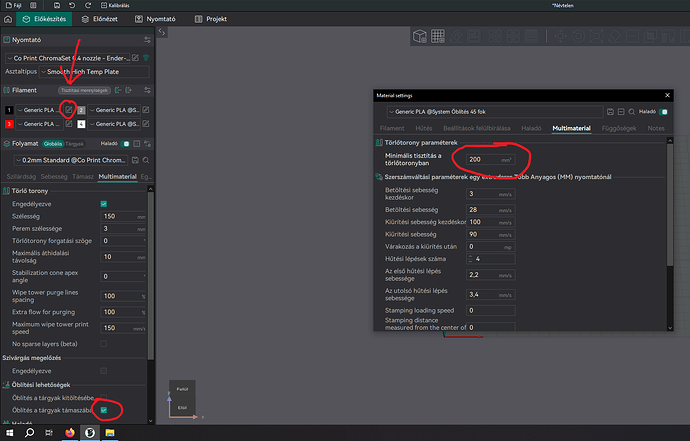

At the same time, in your cheeks, I stuck that it is not a good printer. You need to use the Co print chromaset 0.4 Nozzle Ender 3 V3 Plus Printer, not the Creality Ender 3 V3 Plus Nozzle.

It is likely that the Printer CFG will be prescribed from time to time.

8 I do not use the blue fasteners to the 1 in Ben, and the Filament replacements are no problem. There was a problem with the Filament Sensor alone, which did not work sometimes, but we also described it above. You can need it in pressed condition. It is advisable to roll the 4 dosing extruder spring screw up to a minimum of half a quarter, up to half the road.

And for the other printing, you can do a rinsing test, but I set it up to 200mm3 for each color and it works well for me. This must be provided separately. I attach a picture of CFG and rinse.

I did this remixed this for calibration, pretty neat

FYI do NOT use purge tower when calibrating purge, or your calculations will be wrong

Thanks I will give it a try. As of the printer setting, yes I know I was supposed to use the “CoPrint” printer, I was just experimenting my modified version of the “Ender” printer. But as of color change, I tried both and no difference found

I will give it a try. Thanks!

Hi everyone I’m new to 3d printing and im having some issues trying to install the firmware for kcm i just cant seem to be able to install because of it saying something that is up to date can someone please help me i would greatly appreciate it and thank you in advance i have a creality ender 3v3 plus

put that file on a USB stick, reboot the printer

do NOT modify any files, everything is already done in that firmware