This is my first time in this forum, so I’d ask that you either forgive or tolerate any mistakes that I might make. If I’ve left an important detail out, simply ask for it.

I’m going to try to simplify and condense this situation as best as I can. I have an Ender 3 V3 SE. It’s new, and is still within its return period. The CR Touch bed level values (Creality refers to it as bed leveling in the system menu, so that is how I will refer to it for the purposes of this thread) on my unit change after every single test. Most of my prints towards the middle of the bed are acceptable if not good, but after a day or so, the z distance between my nozzle and bed will change drastically enough to warrant manual adjustments to the leveling data. The “automatic leveling” that is done when you press the “leveling” button does not work properly, and will see the nozzle calibrated to be either far, far too close to the bed (scratching, rubbing, destroying), or exceptionally far away.

So, I manually edit the bed leveling data each and every time. The problem is that, after perfectly calibrating the bed leveling data using a piece of paper, turning the machine off, back on, and then going back to that same leveling data again, the values that were perfect just minutes before, are now so dangerously off that the nozzle is pinned against the bed. If a hypothetical bed level value of, say, -0.08 for the bottom left hand corner was perfect just minutes before, that same value now sees the nozzle completely pinned to the bed. So much so that I have to change the value to +0.17 in order to just barely free the single sheet of paper that is trapped beneath.

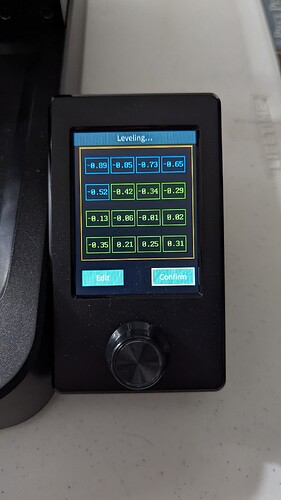

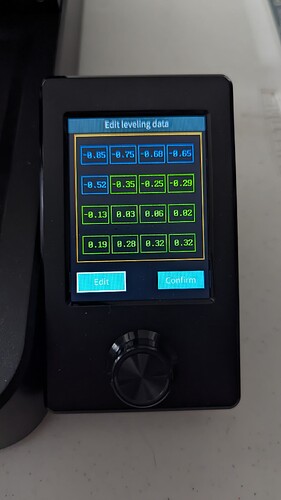

Yesterday, while calibrating, I found that the absolutely perfect bed leveling value for the bottom left hand corner was negative 0.35. Today, it is positive 0.19. This cannot be normal, right? Is it possible that the gantry needs to be leveled? I put two identical glue sticks beneath the gantry and have noticed a teeny, teeny tiny disparity between the glue stick on the left side of the gantry, and the one on the right.

I’ve asked around elsewhere (Reddit) and have been told that this is entirely normal. That the z values for each of the 16 quadrants of the bed are supposed to be drastically different each and every single time they’re tested, even when testing is done back to back. I’ve been told that, for instance, the bottom left hand corner value is literally never supposed to be the same. Cannot be the same. That these numbers do not mean anything whatsoever, at least not for the purposes of the user. It can be -0.80 one moment, and +0.90 the next, and it indicates nothing at all. Is this true? If so, I have absolutely no clue as to how I can address this issue. The nozzle is quite literally leaving small shiny dots on all 16 quadrants of my bed from the automatic bed leveling process, not to mention whatever pressure is exerted when I’m fixing the aftermath of said automatic process manually.

The attached photos were taken only hours apart. Both photos were taken after manual calibration, and represent, at least for the moment these pictures existed in, the perfect distance between the nozzle and bed. Just enough to allow, quite snugly, a single sheet of paper to move beneath.