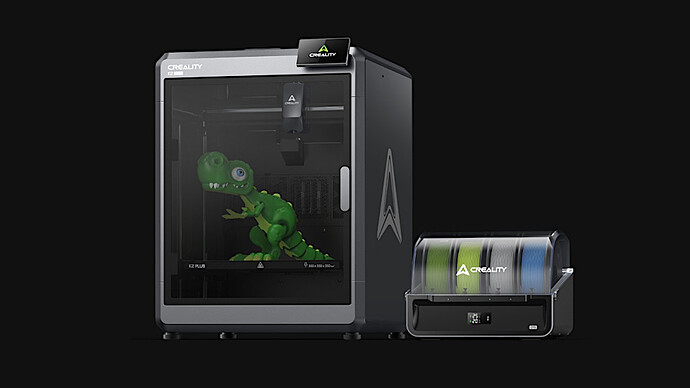

We have conducted research and collected questions regarding K2 Plus and CFS, and we hope this document will be helpful to you.

Creality K2 Plus FAQs

1. What are the key differences between K1 Plus and K1 series (K1/K1 Max)?

K2 Plus is the highest edition in the 2nd generation of K series flagship 3D printers. It offers an ultra-large build volume of 350350350mm and features the latest APUS extruder, a closed-loop motor system, an active chamber heater, etc. And it supports the intelligent CFS unit for multi-color 3D printing and automatic filament backup.

2. Key specifications of K2 Plus?

- 350350350mm build volume;

- 600mm/s max speed, 30000mm/s² max acceleration;

- Nozzle temperature up to 350℃;

- Heatbed temperature up to 120℃.

- Chamber temperature up to 60℃.

3. Is K2 Plus open-source?

K2 Plus uses Klipper-based Creality OS which follows the open source rules. In addition, K2 Plus has built-in moonraker and fluidd service, no need to install it twice; The fluidd port is 4408 and the camera port is 8000.

Please see the Creality announcement on GitHub for relevant information.

4. What are the advantages of closed-loop servo motors?

For K2 Plus, all XYZ axis and the extruder are driven by closed-loop servo motors. Unlike an open-loop step motor, the servo motor offers 32768 micro-steps for each revolution. So it achieves high torque, smooth and quick response, and great step accuracy. The average noise at standard speed is within 50 dB.

Even better, since the motor is regulated by FOC (Field-oriented Control) based on varying voltages. It will greatly reduce the heat runaway and avoid clogs caused by overheating.

5. How is the auto leveling of K2 Plus?

K2 Plus uses two optical distance sensors on Z-axis for auto tilt adjustment and a strain gauge in the printhead for auto leveling. So it can ensure accurate leveling with less compensation.

The whole process is automated without your attention. Moreover, the aluminum heatbed is 5mm thick and hard to deform, so the leveling accuracy can be well guaranteed.

6. The heatbed of K2 Plus is so big. Is it heating fast and safe?

The K2 Plus heatbed adopts an 800W high-power AC heating system with double safeguards. For one, there is an overheating fuse under the heatbed which will automatically disconnect in overheating. There is also a fuse in the machine body. When an unexpected situation occurs, it will disconnect to ensure safety.

7. How many AI cameras does K2 Plus have?

K2 Plus has two cameras. One is located close to the nozzle. It is used for flow rate and PA (Pressure Advance) calibration. Another is attached to the front frame. It is used for video monitoring and print failure detection.

8. How can I print 16 colors?

Currently, the K2 Plus Combo has one CFS, which only supports four-color printing; if you need to print 16 colors, you need to connect four CFSs, and we will provide a stand-alone version of CFS for sale in the future.

9. The K1 series had 3 Z-axis, now the K2 has dual z-axis, is it one less?

The K series features a one-to-three design for its Z-axis structure. Although it appears to have three lead screws, only one of them moves, and it is equipped with a single Z-axis motor. The configuration consists of three lead screws, three guide rails, and one Z motor.

The K2 Plus is an independent dual motor, and is a servo motor, Z-axis force is greater, K2 Plus Z-axis architecture: two screws + four optical axis (thicker) + 2 Z motor.

10. K2 Plus nozzle strain gauge levelling method is unique to K2, compared to other levelling methods have some advantages?

The K1 series is 4 strain gauges distributed in the four corners of the hot bed, while the K2Plus is a high sensitivity strain gauge mounted on the hot end; compared with the K1 series, it has the following advantages:

- Reduced quantity helps control quality and increase yield

- K1 series strain gages on the hot bed, the trigger force needs to be very high, low sensitivity, which is the main reason why the K1 series is not well leveled.

- Strain gages on the nozzle, the trigger force is reduced, the sensitivity is increased and the levelling detection data is more accurate.

11. Does the K2 Plus support LAN and Internet file transfer? Network specifications?

K2 Plus supports CrealityPrint5 LAN control and file transfer, you can control or transfer files to the machine via cloud service after connecting the machine to Creation Cloud.

K2 Plus supports Creation Cloud to connect, view the camera, operate the machine or click on the local file to start printing and print end reminder.

Binding machine can use the Creative Cloud app home page click sweep code binding, K2 Plus temporarily can not use the Creative Cloud slicing function, our cloud slicing is replacing the multi-colour new engine, the old slicing engine k2 Plus can not be used, is expected to complete the switch before 24 December to support the k2 Plus, please wait patiently.

K2 PLus support wifi connection and network cable connection network

- LAN uses http protocol and websocket interface, and video streaming uses webrtc protocol.

- Cloud service uses http protocol and mqtt interface

- K2 Plus wifi specifications: 2.4GHz and 5GHz IEEE 802.11 a/b/g/n/ac, 802.11ac supports up to 433.3Mbps transmission speed

12. Why is the print size 350mm and not larger?

Considering the international freight and home use environment needs, print size and then larger will lead to an increase in the machine form factor and packaging size, shipping costs will increase dramatically, which will make the product cost increase, ultimately leading to a significant increase in the final price, we research to the professional level machine print size and user needs are basically within 350mm, so we take into account the needs and cost-effective decision to do 350mm.

Creality CFS FAQs

1. Is CFS any good to me besides multi-color 3D printing?

K2 Plus uses Klipper-based Creality OS which follows the open source rules. Please see the Creality announcement on GitHub for relevant information.

2. Does K1 series/Ender-3 V3 series support CFS?

Not yet. To make the K1 and Ender-3 V3 series compatible with CFS, you need to upgrade the extruder. Currently, we are working hard on the multicolor upgrade kit for them, which may include CFS, CFS power adapter, a new extruder with a cutter, a nozzle wiping module, and new firmware. This is a huge project. The Upgrade Kit will not be available in the short term.

3. What filaments does CFS support?

CFS can use any flament spools with a diameter of 197-202mm. Creality paper spools are compatible. CFS supports most filaments such as PLA, PETG, ABS, ASA, PA-CF, but not with flexible filaments such as TPU and damp PVA, BVOH.

4. Does CFS support TPU?

No, CFS does not support TPU. To print with TPU, you can install it on the standard spool holder of K2 Plus.

5. What is the 24V power socket on the CFS for?

Normally, when the CFS is connected to a printer, no additional power is required as it is powered directly from the printer via the 485 cable. However, for some printer models that do not have a dedicated 485 port (such as the K1 and V3 series), a USB adapter is required. In this case, the 485 port is only responsible for data transmission and the CFS must be powered by an additional 24V power supply.

People Also Read: