Creality Cloud displays the latest Error Code (still being updated). When a fault prompt appears, just look at the numbers (the English letter code in front indicates the faulty module). Refer to K1 Max fault code and troubleshooting for specific solution, which is common to K1 series fault codes.

Note: The error code consists of the fault location code and error number. You can only enter the numeric code for a query.

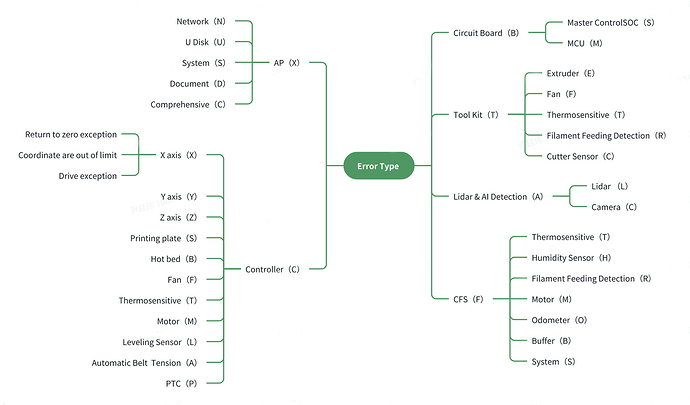

Error Code Type

- A indicates Lidar & AI Detection, L indicates Lidar, C indicates Camera.

| Error Code | Error Module | Applied Printers | Fault Description | Troubleshooting |

|---|---|---|---|---|

| AC0101 | AI Detection | K1C,K1 Max,K2 Plus | A print quality problem has been detected and printing has been paused | 1. This function is used to determine whether there is a printing failure during printing. It is currently mainly used to determine pasta phenomenon. 2. If false alarms are frequent, adjust the sensitivity to normal or turn off AI: Settings - Camera - AI Function |

| AC0103 | AI Detection | K1C,K1 Max,K2 Plus | Detected a problem with the print quality of the first layer, printing has been paused | The platform plate is glued white, or the use of special platform plate patterns may be misdetected, and the algorithm is continuously optimized. |

| AC0104 | AI Detection | K1C,K1 Max,K2 Plus | Foreign object detected on the printing platform, printing paused | 1. This function is to determine the situation that whether there are other objects on the printing platform or no platform during the Z-axis homing before printing, and to suspend the Z-axis operation in time. 2. If there is an occasional false alarm, click Retry, and it will return to homing again. |

| AC0500 | AI Detection | K1C,K1 Max,K2 Plus | Printing quality problems detected by AI | 1. If you can continue to print under the wrong trigger condition or manual judgment, you can click on the machine screen/Slicing Software/Creality Cloud to continue printing 2. If the printing fails, you need to clean the printer and restart the printing. 3. You need to enter System Settings -Camera - AI Function to turn off the function. |

| AC0503 | AI Detection | K1C,K1 Max,K2 Plus | Detected a problem with the print quality of the first layer | If you can continue to print under the wrong trigger condition or manual judgment, you can click on the machine screen/Slicing Software/Creality Cloud to continue printing. |

| AL0504 | AI Detection | K1 Max,K2 Plus | Current file does not support flow detection | Potential Reason |

| AL0505 | AI Detection | K1 Max | AI LiDAR anomaly | Check cable connections to the LiDAR |

- B indicates Circuit Board , S indicates Master Control SOC, M indicates MCU

| Error Code | Error Module | Applied Printers | Fault Description | Troubleshooting |

|---|---|---|---|---|

| BM2512 | Circuit Board | K1C,K1 Max,K2 Plus | The motherboard temperature is abnormal | Possible reasons: 1. The temperature of the mainboard is too high, check whether an abnormal heat source appears to near the mainboard; 2. The mainboard is not cooled by its fan. 3. The mainboard is faulty and needs to be replaced. |

| BM0110 | Circuit Board | K1C,K1 Max,K2 Plus | Motherboard Connection Failure | Possible reasons: 1. Cables of the mainboard are abnormal; 2. The mainboard is damaged. |

| BM0111 | Circuit Board | K1C,K1 Max,K2 Plus | Nozzle connection abnormal | Possible reasons: 1. The wiring of the hot end circuit board is abnormal. You can check the wiring and re-plug it. 2. The hot end circuit board is damaged and needs to be replaced. |

| BM0112 | Circuit Board | K1C,K1 Max,K2 Plus | Hotbed Connection Abnormal | Possible reasons: 1. The wiring of the hot bed circuit board is abnormal. You can check the wiring and re-plug it; 2. The hot bed circuit board is damaged and needs to be replaced. |

- C indicates Controller, X indicates X-axis (Return to zero exception/ Coordinate are out of limit/ Drive exception), Y indicates Y-axis, Z indicates Z-axis, S indicates Printing plate, B indicates Hot bed, F indicates Fan, T indicates Thermosensitive, M indicates Motor, L indicates Leveling Sensor, A indicates Automatic Belt Tension, L indicates PTC.

| Error Code | Error Module | Applied Printers | Fault Description | Troubleshooting |

|---|---|---|---|---|

| CB2510 | Controller | K1C,K1 Max,K2 Plus | Hotbed thermistor open circuit | Possible causes: 1. Hot bed thermistor wire connection problem. Check the thermal wire, re-insert it. 2. Hot bed thermistor internal damage. Replace thermistor. |

| CB2516 | Controller | K1C,K1 Max,K2 Plus | Hotbed thermistor open circuit | Possible causes: 1. Hot bed thermistor wire connection problem. The thermistor wire is broken, resulting in short circuit. After troubleshooting, repair the damaged part to check whether it is restored 2. Hot bed thermistor internal damage. Replace thermistor |

| CB2565 | Controller | K1C,K1 Max,K2 Plus | The heat bed is not heating as expected | Please check hot bed themistor and hot bed heater related error troubleshooting. |

| CT2511 | Controller | K1C,K1 Max,K2 Plus | The chamber thermistor may be open circuit | Possible causes: 1. Cavity thermistor wire connection problem. Check the thermal wire, re-insert it; 2. Cavity thermistor internal damage. Replace thermistor. |

| CT2517 | Controller | K1C,K1 Max,K2 Plus | The chamber thermistor may be short circuit | Possible causes: 1. Cavity thermistor wire connection problem. The thermistor wire is broken, resulting in short circuit. After troubleshooting, repair the damaged part to check whether it is restore; 2. Cavity thermistor internal damage. Replace thermistor. |

| CM0115 | Controller | K1 Max,K2 Plus | Detected unfinished task, do you wish to continue printing | Possible causes: The printer suddenly powers off while printing, which triggers the power loss recovery function. If you print something halfway, you can continue printing. If there are fewer printing parts, we suggest that you restart to print. |

| CX2573 | Controller | K1 Max | X-axis homing abnormality | Possible causes: X axis limit is not triggered. Check whether the limit is damaged (K1 series may be soft limit problem, which need to check whether the motor drive is damaged). |

- F indicates CFS (Creality Filament System) , T indicates Thermosensitive, H indicates Humidity Sensor, R indicates Filament Feeding Detection, M indicates Motor, O indicates Odometer, B indicates Buffer, S indicates System,

| Error Code | Error Module | Applied Printers | Fault Description | Troubleshooting |

|---|---|---|---|---|

| FR2833 | CFS | K2 Plus | Feed issue, check for filament or spool jams. Click “Retry” after resolving. | CFS light: single red flash. Possible causes: filament entangled or jammed, or filament jammed in extruder or bottom bracket. |

| FR2832 | CFS | K2 Plus | Retract issue, check for filament or spool jams. Click “Retry” after resolving. | CFS light: double red flash Possible Cause: Filament entangled, or filament stuck in extruder or bottom bracket, or filament not properly tightened during material withdrawal. |

| FR2839 | CFS | K2 Plus | 1D(example)filament runs out, please refill. | CFS Light: Red light breathing Possible cause: 1A [Example] filament is exhausted and no new filaments are loaded |

| FR4828 | CFS | K2 Plus | 1D(example)filament may be broken in CFS. | CFS light: Red light is always on Possible causes: The filament is stuck in the five-way and cannot be sent to the extruder normally and cannot be retracted normally. |

| FS2840 | CFS | K2 Plus | Command failed, current scenario does not support this command. | There may be other commands being executed or other situations that prevent the next command from being executed. |

| FB2844 | CFS | K2 Plus | PTFE tube may have detached from the pneumatic fitting, Printing paused, please try again after resolving | Error description: It usually occurs when the pneumatic joint is loose somewhere in the Teflon tube channel of the machine, causing the filament to be fed all the time; after this message is prompted, first click on the screen to rewind the filament. If the rewind is not enough, you can click on the rewind again; when the rewind is complete, you can reinstall the pneumatic joint and continue to use the machine. |

| FO2845 | CFS | K2 Plus | Extruder may be clogged. Click “Retry” after resolving. | Error description: When rinsing the filament, the five-way meter does not increase. The filament may not move and the extruder may be blocked. It is necessary to check if the filament is tangled, stuck, planed, or if it is not being sent normally into the throat of the extruder, which may be blocked. |

- T indicates Tool Kit , E indicates Extruder, F indicates Fan, T indicates Thermosensitive, R indicates Filament Feeding Detection, C indicates Cutter Sensor

| Error Code | Error Module | Applied Printers | Fault Description | Troubleshooting |

|---|---|---|---|---|

| TE2509 | Tool Kit | K1C,K1 Max,K2 Plus | Unable to obtain nozzle temperature, the thermistor may be disconnected | Possible reasons: 1. If the thermal cable to the hot end is faulty, check the thermal cable and reinsert it;2. The hot end thermal is internally damaged. Replace the thermal or hot end. |

| TE2515 | Tool Kit | K1C,K1 Max,K2 Plus | Nozzle temperature exceeds limit, thermistor may be short-circuited | Possible reasons: 1. There is a problem with the thermal wiring at the hot end. The thermal wire is broken, leading to short-circuited. After troubleshooting, some wires can be repaired to see if it is restored. 2. The hot end thermal is internally damaged. Replace the thermal or hot end. |

| TE2564 | Tool Kit | K1C,K1 Max,K2 Plus | The nozzle is not heating as expected | This is a comprehensive error report, please check hot bed thermal and hot bed heater related error troubleshooting methods. |

| TE2111 | Tool Kit | K1C,K1 Max,K2 Plus | The nozzle temperature is below the minimum extrusion temperature | Possible reasons: 1. The extrusion temperature is lower than the minimum temperature set by the machine configuration, and the minimum extrusion temperature limit of Creality OS is 170°C; For slicing problems, please use the official slicing software or contact cs@creality.com to get the slicing file provided by the official third-party; 2. If the hot end is damaged, check other heating error solutions to the hot end. |

| TE2762 | Tool Kit | K1C,K1 Max,K2 Plus | Detected a problem with the print quality of the first layer | If you can continue to print under the wrong trigger condition or manual judgment, you can click on the machine screen/Slicing Software/Creality Cloud to continue printing |

| TE2761 | Tool Kit | K1 Max,K2 Plus | Current file does not support flow detection | Potential Reason |

| TR0116 | Tool Kit | K2 Plus | Filament run out, printing paused, please refill | Possible reasons: 1. When the filaments are exhausted, trigger normally. Follow the on-screen filament replacement process to load filaments and then print again. 2. False triggering, the material break detector needs to be replaced. |

| TR2852 | Tool Kit | K2 Plus | ||

| TR2863 | Tool Kit | K2 Plus | Retract issue, extruder filament sensor anomaly triggered, filament may have broken inside the extruder. | During the use of CFS, if the extruder break detection is abnormally triggered after the filament is unloaded, it may be because the external material rack is inserted or the material is broken in the extruder during unloading. |

| TC2841 | Tool Kit | K2 Plus | Cutter issue, cutter might be jammed, please try again after resolving | During the cutting process, it is detected that the cutter may be stuck or there may be no cutter. |

| TC2854 | Tool Kit | K2 Plus | Filament detected in the extruder, affecting the cutter calibration. Please unload the filament and try again. | 1. During the vibration optimization operation, it was found that there are filaments in the extruder. When you start the function, it is necessary to ensure that there are no filament in the extruder. 2. You can manually click to Retract (Unload filament). If the filament fails to be retracted when cutting continuous filaments, you can unlock the motor, hold the extruder against the cutter push rod, and then click to retract. |

| TC2855 | Tool Kit | K2 Plus | Cutter calibration failed. Please try again after resolving. | Cutter position calibration failed during vibration optimization |

| TC2856 | Tool Kit | K2 Plus | Cutter issue, the cutter may be jammed or missing. Click “Retry” after resolving. | During the process of cutting off, the cutter may be stuck or there is no cutter. |

| TF0501 | Tool Kit | K2 Plus | Heat break fan speed detected to be too low. | Possible reasons:1. The cable terminal is loose. Reinsert it in again and check whether it is restored. 2. During the installation, the fan is locked by the screws and cannot rotate. Check and rectify the fault to see whether the fan recovers. 3. The fan is damaged, replace the fan. |

| TF0526 | Tool Kit | K1 Max | Model fan speed detected to be too low. | The speed of the model fan is lower than the set value. You need to check whether the wiring is good or stuck. |

- X indicates AP, N indicates Network, U indicates U Disk, S indicates System, D indicates Document, C indicates Comprehensive

| Error Code | Error Module | Applied Printers | Fault Description | Troubleshooting |

|---|---|---|---|---|

| XS2000 | AP | K1C,K1 Max,K2 Plus | System error, try restarting | The system crashes and needs to be powered off and restarted for analysis. Export logs to contact cs@creality.com. |

| XS2001 | AP | K1C,K1 Max,K2 Plus | System error, try restarting | The system crashes and needs to be powered off and restarted for analysis. Export logs to contact cs@creality.com. |

| XS3000 | AP | K1C,K1 Max,K2 Plus | System error, try restarting | The system crashes and needs to be powered off and restarted for analysis. Export logs to contact cs@creality.com. |

| XS3001 | AP | K1C,K1 Max,K2 Plus | System error, try restarting | The system crashes and needs to be powered off and restarted for analysis. Export logs to contact cs@creality.com. |

| XS3002 | AP | K1C,K1 Max,K2 Plus | System error, try restarting | The system crashes and needs to be powered off and restarted for analysis. Export logs to contact cs@creality.com. |

| XS2060 | AP | K1 Max,K2 Plus | System error, try restarting | The system crashes and needs to be powered off and restarted for analysis. Export logs to contact cs@creality.com. |

| XS2093 | AP | K1 Max | System error, try restarting | The system crashes and needs to be powered off and restarted for analysis. Export logs to contact cs@creality.com. |

| XD2571 | AP | K2 Plus | Print file is corrupted | The current print file cannot be parsed and needs to be re-transmitted or renamed before being sent to the printer for use. 1. The file name or some characters in it may not be recognized by the firmware; 2. The file may be damaged during transmission. |