Hey everyone,

after my own experience with the Ender 3 V3 SE in combination with the Nebula Smart Kit i have to write this, because i am almost done with creality.

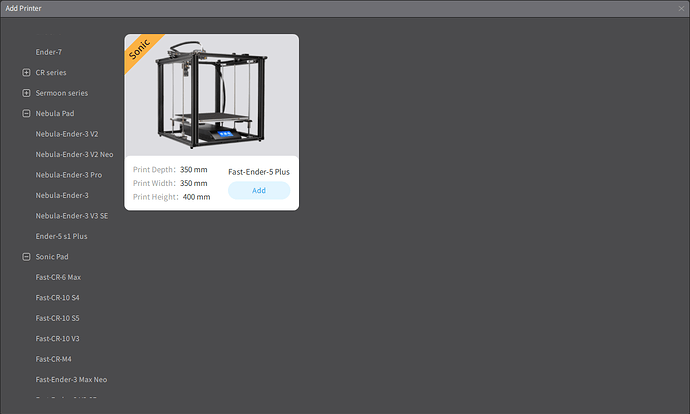

Last year i bought the Ender 3 V3 SE, it is my first 3D printer. I started to print with TPU and i had some really great results so far. Now i used the printer more and more and when i was tired to move always to my printer in the kitchen, i had a look for wifi support and found the nebula smart kit. Seems like a great Kit and upgrade at all. Not just wifi support, a camera, use the smartphone at work to check a very long print maybe?!

Yeahhh thats nice!!!

So i bought it, installed it, made the firmware update, g sensor whobble test and so on and everything was working well for the first couple of prints. I was really impressed, fast and got for that speed a great result and then everything turned into all the negative things you are able to read everywhere about this kit. Why it is always the same, you just find the bad stuff, when it is too late?

The noozle scratched the bed, while i started the selftest, while to measure and or autolevel the bed. Sometimes i have the z bug and the printer seems to print the first layers straight above the bed and after a while of printing the printed part just fly away and you get not really tastefull spaghetti. But a bit more annoying is that i also got the Y layer shift, whats really nice after you got finally a good start and after 3 hours of printing the part get the shift…

After i got all the problems, i found out that i am not the only one with such issues. It seems it is usual for this pad and i was reading so many things how to solve, i have to root, have to install weird stuff onto my computer, to make something to get onto the printer config, so much videos i was watching about something what you can do to solve some problems…

Creality, is this your intension to your customer? That i buy your product and have to do such stuff before your product will work?

I want to buy something what i want to use and not i just want to try make work. I already lost almost 1 kg of filament for trying stuff to get this printer pad combination work, without to root or to hack into the printer just to get to a config. Who is gonna pay my free time i lost, i had to invest, just to get more and more dissapointed of this product and had to put more and more money, i mean useless plastic into my trashcan… I run out of good mood and you make me loose my interest in this hobby.

The printer as V3 SE itself printed ways more better than now after this massive “Downgrade”. And there you also had more options to configurate. For example, why i do not have or get access onto the printer config, or have or get the possibility to set the acceleration to the speeds the printer is really able to work with and not have to use the standard configuration of 5 times too much acceleration or speeds which you creality set as standards into the config, what also may causes damage to the printer itself, like the motors or belts.

I tried to change the acceleration and speeds in creality print before slicing and even then i got those issues. Belts are tight but not too tight and in great condition.

Is there no easy and official solution, instead of rooting or to hack myself into the printer?

Do you really ignore all the negative comments and reviews about this? When are you going to solve all those problems? When we, your customers can count with a solution to make the printer work great?

Should i buy more stuff? Add new stronger bars, add better motors buy a z axis stabilizer, a new printhead maybe until everything works like the config says it has to work? Or i habe to hack into the system, root the stuff to use better software and configs instead of your owns? Is this your intension to us customers creality?

I just know, without a simple solution, i will not print any longer with this thing. I do not waste my money and my time any longer with this, just to throw everything away i was printed for tests, tests and even more tests. Because i know, i will not get anything back of you. I wasted too much money and time already. It is a gamble to print over and over again one single piece for a result i will be happy with! After kilos of wasted plastics and money until i got finally a good printed part? Is this your intension creality?

This is no fun any longer, i am really dissapointed!

Thank you for reading and for understanding.

Michael