I am just curious; how many of the 3D users here have done the full Creality Print Calibration ?

Just the printing takes 7½ hours.

And what was the outcome?

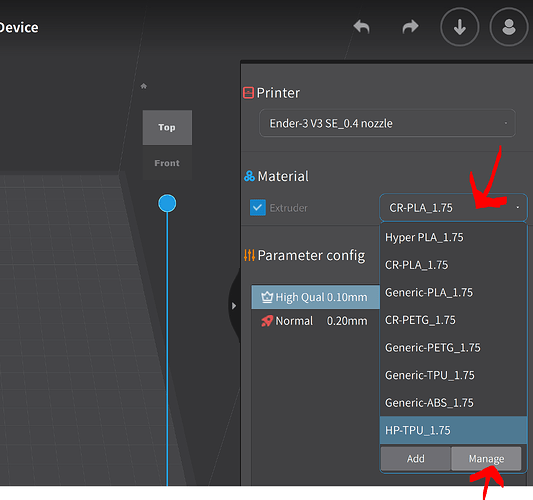

Do you mean temperature, flow rate…?

If so I have only successfully completed the Temp and Max Flowrate in the listed times. My attempts to complete the Flow rate (2 times. image below) have failed miserably and I can’t figure out why. Curiously I’ve made successful prints fairly consistently. I just can’t get past the Flow rate calibration. My temp and Max flow prints came out very nice.

Yes, 6 test of temperature and flow.

I just made the temperaturetest and I can see I need to go up something like 15-20°C. I´m surprised!

It must be possible to get it all right, if not some mechanical problems show up. Many issues ahead with 3D-printing.

I can´t tell what caused Your prints flow rate fail, but I myself will probably get to this, days ahead.

I made the temperaturetest and found out my temperature needed to be raised 15-20°C so I did in the profile. BUT when I saved the Flow Coarsetest and printed it out, the temp on the display showed 190°C ! Why? I saved the profile with 220°C but nevertheless it used 190°C and the flowrate on the display showed 100% the whole time even when it should be ex 80%.

I can see differences in the print but the display has it´s own life.

Shouldn’t the digits on the screen change when the parameters in the printing change? As I recall it did in temperaturetest.

I can of course not trust in this Flow Coarsetest when the temperatur isn´t the right!?

Finaly before the second time I printed the Coarsetest I whent into the Gcode file and canged the temperatur digit till 220, but in the printer it still kept on with 190.

Do I need to close down the printer to clear the memory?

I finaly manually on the screen changed to 220°

”Strictly speaking, there’s no difference between extrusion multiplier (a whole number) and flow rate (is expressed as a percentage).” (printingit3d.com)

Your picture, Lensman, of the flow rate really looks strange! You have right temperature? The bed is leveled right? The 3 models to the right looks like there hardly are comming any filament out or it´s melted?

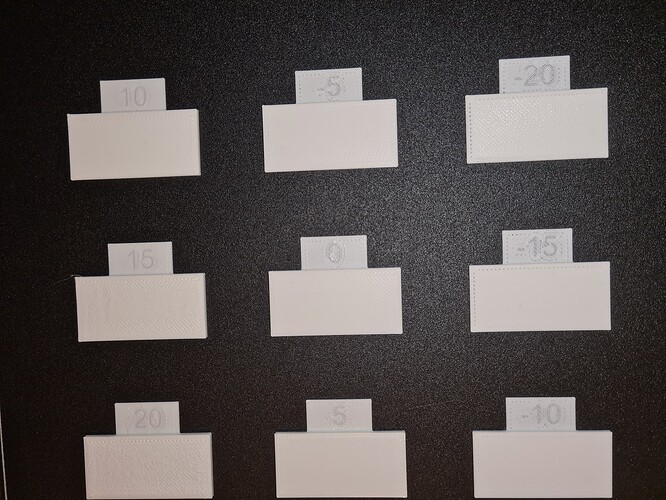

Compare with mine at the right temperature:

@hyl77Swe Yes, I can clearly see the difference and I’ll take yours please ![]() .

.

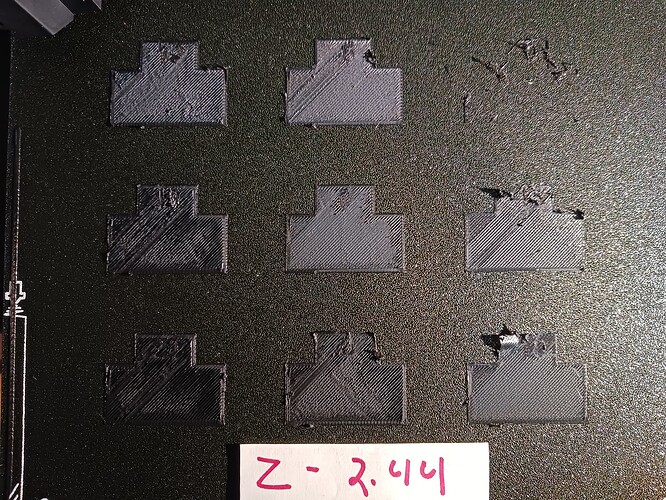

The image I posted is not a 100% finished print. I had to stop the printing on the first/second pass because it would have dragged the filament when it got to the far right column.Total mess!

I’m a “fledgling” when it comes to 3D printing so I’m not exactly sure what is “normal” and what is not. One thing I do know is that that test was not normal ![]()

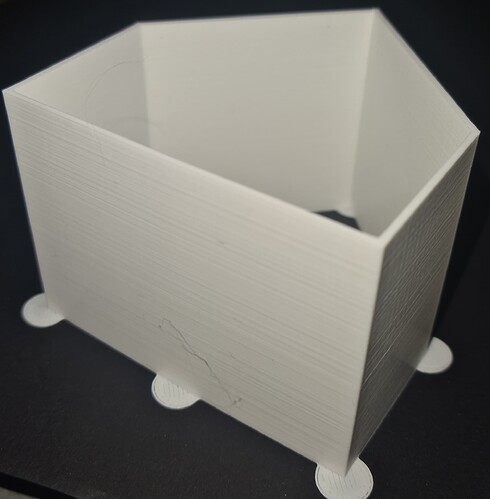

I’m stumped because I’ve made “successful” prints (image) with no apparent issues so I’m pretty sure the temps I’m using are fine(?). But then again I have no idea.

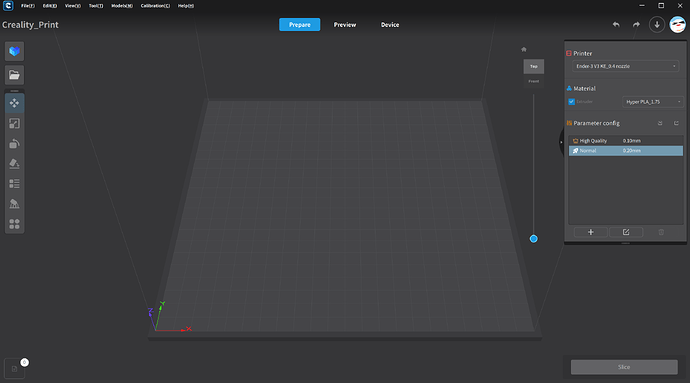

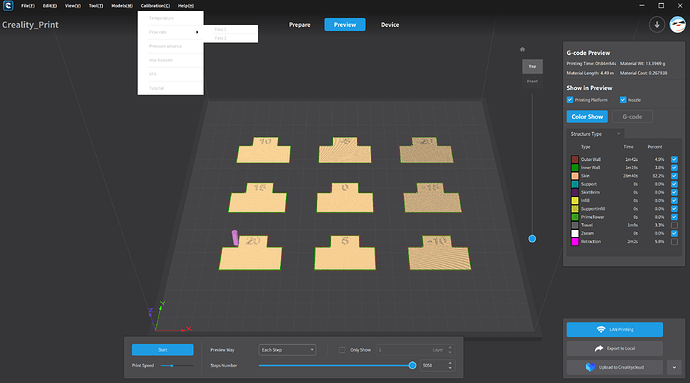

How did you set the temp? I looked for adjustments but didn’t see any. In fact when I do the calibration tests the only view I get is in “Preview”. And in that tab I can’t adjust anything. You need to be in “Prepare” to make the adjustments. Did you do “One Click Printing” or did you send the G-Code and adjust on the printer side?

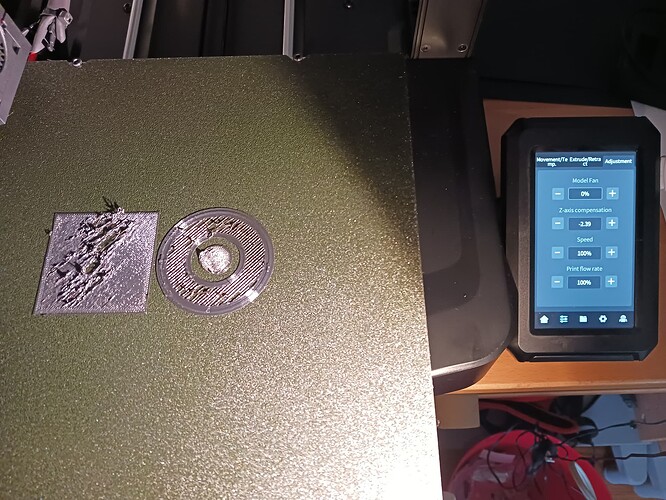

Great, I’ll try that. I’m having miserable failure after failure even with adjusting the Z and installing the latest firmware update. If this keeps up I’m going to send it back for a replacement. It shouldn’t be this hard (and I’m pretty tech savvy).

![]()

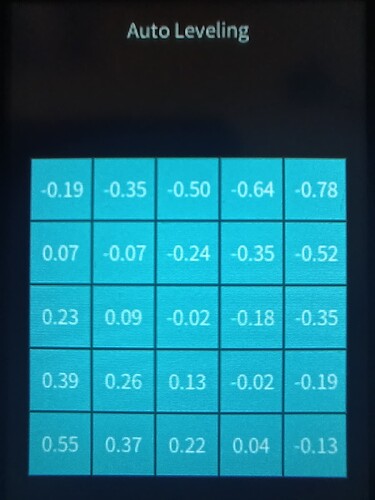

Does the auto leveling not work? What data does it show when leveling finished?

I assume it’s “working” (see image)

but I can’t get consistent first level adhesion AND I can’t even complete all of the calibration tests. I’m not sure how I can successfully make the best prints possible if I can’t even calibrate it?!

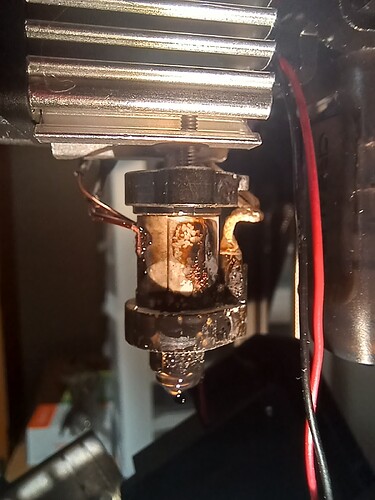

I just now stated to smell some burning plastic so I took off the cover only to find the head was enveloped in filament (or at least I think it was filament).

I heated up the nozzle with the cover off and it started smoking. I cleaned it as best I could and it’s not smoking now. With the latest firmware installed (?)

I’m attempting to start over again but am not having much luck as you can see

I’m coming to the conclusion something is not right no matter how I adjust the z offset. I’m within the window of replacement or just sending it back so I think I’m going to have them send another one and start over.

Might not be of any help but in Creality Print if you want the printer to calibrate as it’s printing make sure to select this checkbox. The printer will adjust the Z offset automatically as best it can.

Ok, You have the KE version its not exactly same version as my SE. The leveling looks quite good; why do You continue with the Z offset? Do You clean the bed properly with alcohol before printing?

What numers shows the display about Z ?

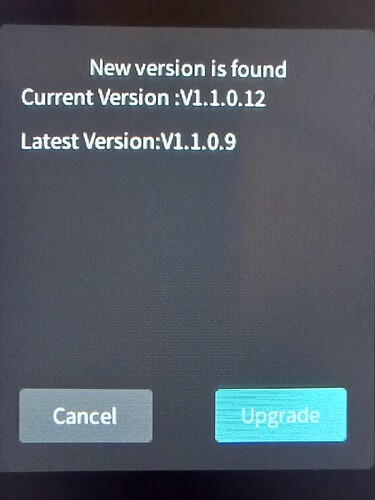

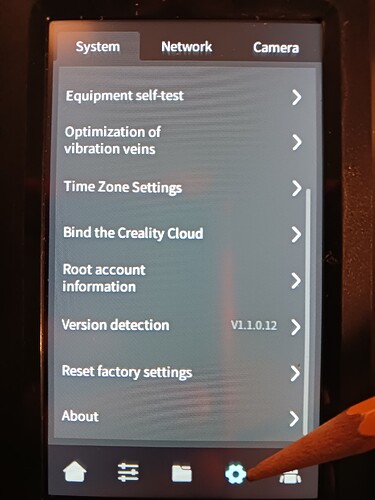

You can get a newer firmware V1.1.0.12.

How You get filament (black?) around the ceramic heater I cant tell but there could be something wrong with Your printer.

Contact the support and ask what You should do if nothing change.

Yes, I just updated the firmware to 1.1.0.12 (I think) but it keeps saying a new version exists 1.1.0.9 which is actually the old version I upgraded from. Every time I start the machine now it asks me if I want to update even though I have the update ![]()

The bed is cleaned with IPA.

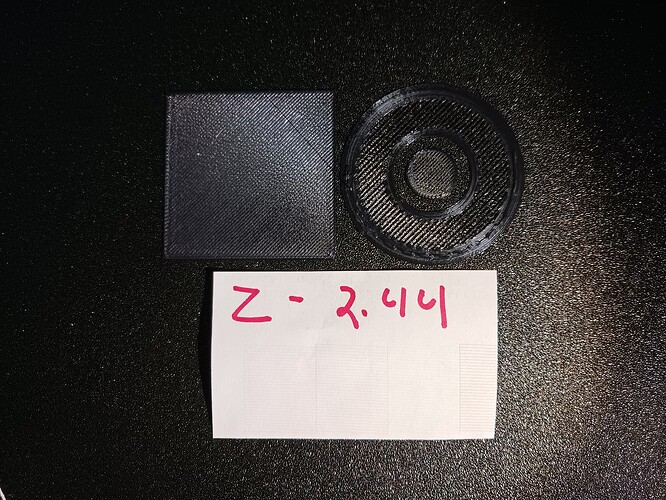

The auto setting for Z offset give me an unusable first layer and just slides off the bed so I had to keep adjusting it to fine one that will stick. I finally found that a Z offset of -2.44 instead of the Auto Calibration of -2.39 allows me to get a smoother first layer HOWEVER I still can’t successfully complete the flow test (although it was much better).

I think I have a “lemon” and am going to send it back for a new one and see what happens. If it does the same thing then I’m off to a Bamboo printer. Frustrating! ![]()

We have not talked about heated bed? What filament are You using, do You have the right temp on the bed?

I believe the bed was 60° and the print temp 220.

What stumps me is if I have 8/9 adhering to the bed at 60°/220° then why is that last patch failing if the bed is level? Is the flow of that last patch too little?

The Z offset solved 99% of the adhering issue for this particular test and going any more +/- on the Z makes it worse.

I’m running a vertical print now and the base seemed to print fine without any dragging and without a brim for support. At least it’s still standing!

Do You use the Nozzle cleaner and a needle to avoid the nozzle become clogged?

Apart from when the head drags filament off the bed and gets stuck the nozzle extrudes fine so I haven’t felt the need to poke it with the needle or replace it yet. I’ve raised the gantry to the top and did an extrude finding that the nozzle output was fine and consistent. I have an extra nozzle which came with the unit but that will be my very last resort before I have them replace it. Luckily I bought it through Amazon and I’m still in the return window which is until 1-31. Hopefully I can figure it out by then.

Lensman , did You come any further?

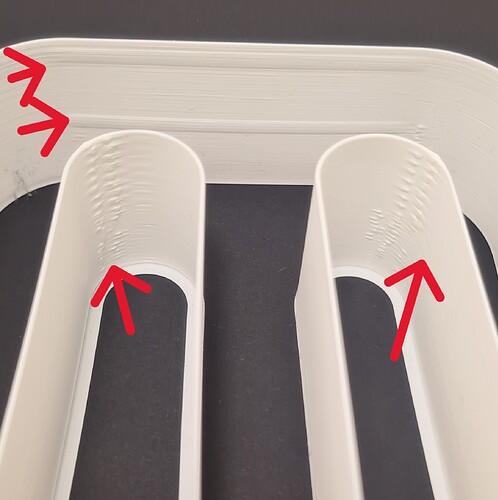

I did two more testprint and I do not quite understand whats going on. PA-test, what should I do with this?

Maximum Flow Volume Calibration,

I have no gaps, but what are the issues with the red arrows?

I"ve seen that issue in others Benchy prints on rounded corners. I think that can be viewed as symmetrical for sure. It’s weird because my KE will print those tests fine but not the flow ones. And your flow ones came out fine right? Your first image doesn’t look horrible but definitely not right.

I just found this link.

It covers quite a few issues. I’ll try and look for your issues along with mine and report back if I find anything useful.

FYI on the Max Flow test mine has the horizontal “bumps” (the very back & top of your image) too. So I think that’s supposed to be there but not the issues with the interior curves.