Ich bin neu beim Thema 3D Druck und habe den Ender S1 Pro erworben.

Montiert, Bett leveling durchgeführt und Beispiel Hase gedruckt, perfekt.

Bei meinen ersten Teilen sind die Bodenschichten perfekt, ab dem Infill "hör"t man den Druckkopf bereits beim Bewegen, die Schichten bauen sich weiter auf, dann wird das Teil vom Bett gerissen. Habe den Fluss verringert, Geschwindigkeit reduziert.

Ich weiß nicht mehr weiter…

Hi @Tommy and welcome to the forums and the wonderful world of 3D printing!

Sorry to hear you are having bed adhesion issues. Make sure that between prints you thoroughly clean your print bed as the smallest bit of grease or residue could cause a print to fail. Wipe the build plate with something like IPA and that will remove all grease and residue which will help with adhesion.

You could also add a brim to your print, this will print small lines around the outer edge of your object to try and help keep it stuck down to the bed. Or you could also try adjusting your print bed temperature, I find the best temperatures for PLA is around 50-60 degress C bed temperature.

Try only changing one thing at a time so that you don’t lose track of what improves or worsens the print quality so that you can easily undo them if need be ![]()

Thanks for your answer. I do not have bed problems, the ground layers are perfekt. I have problems, when the infill starts. after 2 or 3 infill-layers you can hear the head cratching over the part. the surface is getting rougher, some “balls” appear, til it is too much. At the first print, the head stuck and lost position.

Maybe give us a few more details like what slicer you are using, temps, material.

Check your slicer settings too… I’ve made some changes and then forgot to set them back and that caused some problems… ![]()

It sounds like your printer may be over-extruding slightly. I would run some calibration tests or reduce the flow rate of your hotend slightly to see if it cures the issue. Another option is to change the infill pattern to one that doesnt cross over so much on each layer.

Here is a link to the Creality calibration tutorial if you need it:

Creality Print Calibration Tutorial

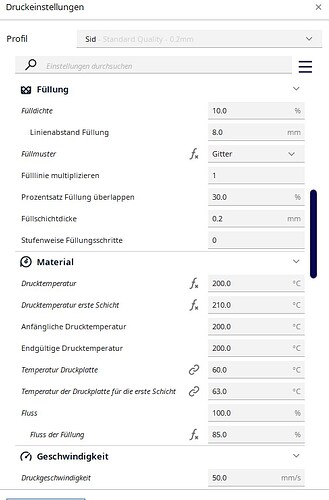

I use the Cura slicer. Temp. 200/60 C. 50mm/s. As I heard, the Standard setting should be ok. The information I got, was to reduce the flow, too much material for the infill. I set the flow to 95%, didn’t work. Next I will try to set the flow to 100%, the flow for infill to 90%.

I would definitely keep playing around with extrusion/flow rates as it does sound like your printer is slightly over-extruding in some areas of the print. If you do the calibration tests it will tell you exactly what setting you need for the perfect printing parameters ![]()

I would recommend checking your temperatures. Ideally you want to be keeping the nozzle at the same temperature throughout the print rather than printing the first layer 10 degrees hotter.

Also check your bed temperature, try reducing your initial bed temperature to 55 and rest of the print to 50. This should help the first layer stick and then cool down correctly.

I had some tear off, so i increased the bed temerature. I will reduse it.

With flow 75% is was a little bit better, printed a couple of layers more before tear off.

Looking at your photo I would also lean towards the filament being damp. Usually when filament absorbs moisture it tends to boil off the moisture when it passes through the hotend but as a result the filament will kind of bubble and distort as its laid.

Looking closely at the outer perimeter of your print its showing signs of damp filament. I would recommend drying out your filament and trying again to see if it improves the print quality. You can dry the filament by heating it to around 50 degrees centigrade for approx 3 to 4 hours.

Thanks for your answer. I didn’t think on thank, cause the room has 18C an 31%RF.

31%RF is too much ? I will try it.

You’re welcome, some filaments have a tendency to absorb moisture more than others so it could be that your roll wasn’t 100% dry when you received it and has possibly absorbed more ambient moisture since opened.

I have had a couple of rolls in the past from different manufacturers that out of the box didn’t print right, in fact the perimeters looked identical to what your print does. Once I dried them thoroughly they printed beautifully but if I leave the rolls out for too long they start to print wonky again ![]()

Thanks. I have an originally Roll from Creality.

For test I increased the infill to 20% and reduced the flow for infill to 50% and it worked.

Lets see, was happens next…

So many thanks for your time you spended.

Thats awesome news, so glad to hear your able to get it printing well again.

Stick at it and you will be a pro in no time ![]()

You’re very welcome, always a pleasure to help ![]()

I’m desperate… the last part worked, the new one today had the same problem. Rough surface and than tear off. Humidity is 31%. The first layer is perfekt. The problem ocures up the 2. layer. 3 layers are 1mm thick, it should be 0,6mm. is the flow too much ?

Sorry to see you are still having printing issues.

I would try reducing your layer height slightly to around 0.2mm for best results. I would also try reducing your flow slightly as it does look like its slightly over-extruding.

@Nikoli

Do you think this would be a slicer setting problem… Maybe reset the settings and start fresh…? Just a thought… ![]()