Good evening guys,

I got a second hand ENDER 3 V3 KE with the nebula camera in fair price and I was quite happy until I put my hands on the actual item.

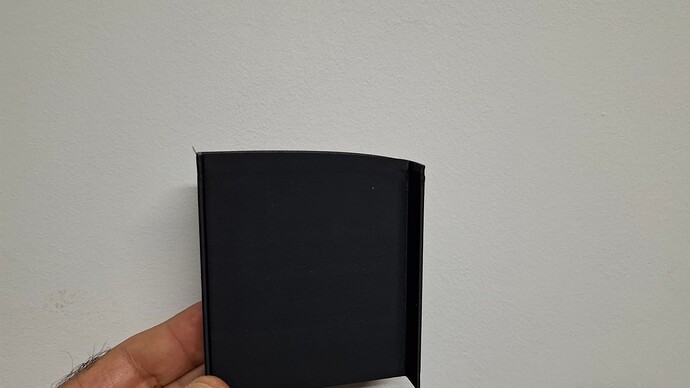

Since first printings noticed that the initial layer (I am newbie hence not familiar with the terminology) are slightly curved, not a straight line.

For such printings I’m using a roll of PLA 1.75 with an average price that was available in a nearby IT shop.

Second finding was a similar curved edge on levels above 6 to 7 cm above hot plate.

I had an extensive chat with the seller who is insisting that this is a matter of leveling and temperature of the hot plate but not a damaged hardware in any case.

The surface (a desk) is perfectly leveled and the hot plate temperature raised form 50 to 60C without any observed improvement.

I have try printing the very same object on different angles of base but the result is always the same.

Bottom layer is curvy towards up and the upper layer is curvy towards down.

As the window of returning is closing, what is your opinion? is this a damaged hardware or it is matter of adjustment (of whatever level, advanced or not) and what I should tune?

I’ll try to post some photos but I’m not sure how I can done this as this is my very first post in the community.

Thanks

Do you have a picture of the curving? Sounds like it might be warping off of the bed.

1 Like

Hi,

you can see the photos.

I have no idea what I should tune or fix but my main concern ATM is the hardware condition.

Is this a hardware issue or a setting/adjustment matter?

Thanks

its a setting issue, the part is coming unstuck from the bed and warping up. So we should be looking at what temperature the bed is and if you have the right z-offset to squish the filament into the bed for best adhesion. If you put a straight edge, preferably a steel rule, across the printer bed in all directions, there any gaps. If you can see it is bent you’ll see gaps, I would send it back. But it is more likely not a bent bad just poor adhesion. What I find with my V3KE is I need to adjust the z down to the bed another 0.1/0.15mm after the autolevel, it is always too high for me. The build plate for PLA should be below 60, preferably 50-55C, higher than 60 and the PLA stays soft and will probably have elephant foot distortion.

2 Likes

I can confirm that there is no any gap and the printer bed is leveled.

Initial tests performed with default settings 220/50/0 C, later increased to230/60/0C with improved results on bigger area prints but with lower height.

I have not idea where I should check the Z-offset setting, could you advice?

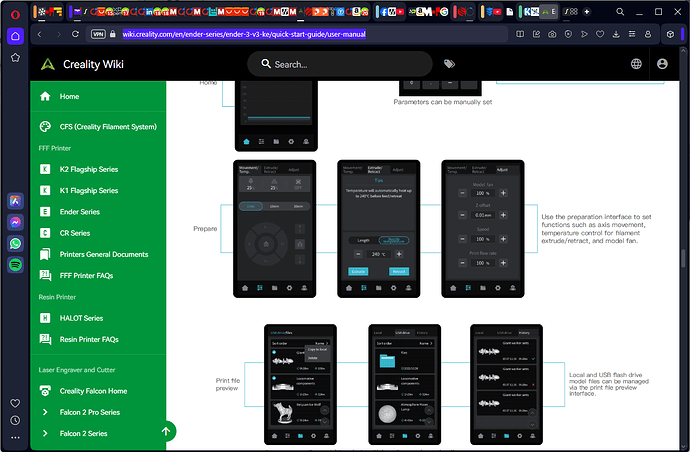

On the prepare screen, its the one with the sliders, bottom left, you will find an adjust screen, top right, z-adjust is on that page. We can use that to adjust the z-offset while we are printing. What I do for setting the printer up is print a big wide skirt around say a benchy. You can adjust the z-offset while it is printing the skirt and you should, with practice get it perfect before the main print. See section 4.3 of the manual

2 Likes

Is this accessible through the menu of creality print or I Should do it locally?

I’m handling the printer via wifi and it is installed in the basement.

I would do it locally to the machine in that way you can watch what happens to the filament whilst you make the adjustment. it is a hands-on thing, but once set it should stay set until you go through a relevelling.

2 Likes

I did some printouts with 65/230 C and first layer setting to 0.4 with extensive support in slicing and results are much better, I can say satisfactory. For the moment, I’ll stay here to digest the lesson learned before diving to the x, y, z axis world.

Thanks