I’ve had my Ender 5 Pro for a couple years now and have had a lot of successful prints. I had to replace the hot end and went with the spider from Creality. I had mixed results. I put on a Sprite Extruder SE Direct drive. I could not get the extruder to get in sync with the spider hot end. Since I print mostly PLA I purchased a new stock Creality Ender 5 Pro hot end. I installed that with the Sprite Extruder SE drive. Now the test line down the side prints perfect, the skirt prints perfect, but when it gets to the piece I’m printing it won’t stick to the hotbed. I’ve tried the stock magnetic bed with painter’s tape, a PEI Sheet Magnetic Flexible Heated Bed, and a Creality glass bed. I had all of these from past printings. The same things happens on all of them. I’m assuming there is something I’m missing in the settings. I’m using the Creality 8.4.2 slicer. I’ve tried different thicknesses of layers, different temperatures, etc. I’ve leveled the bed numerous times. I am running out of ideas. If anyone has any, I would be grateful for any help with this

Hello @Tim_Braun and Welcome to the Official Creality Forum ![]()

Thanks for sharing that. Sounds like you’ve put a lot into that Ender 5 Pro ![]()

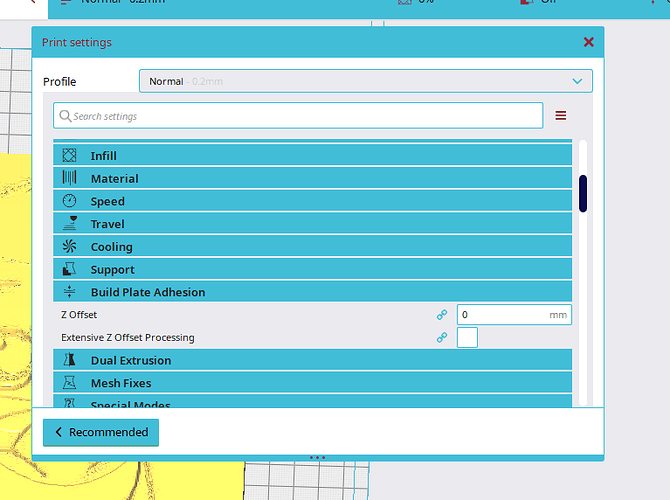

I’m not familiar with the settings yet on Creality Slicer but when using Creality Print there is a setting for the Z offset which will put the nozzle closer or further away from the bed…

Maybe try experimenting with the Z offset settings…???

If the print doesn’t stick to the bed maybe start with a setting of -0.05 would help. This will move the nozzle .05mm closer.

Whenever you change a nozzle or hot end setup this could change this nozzle distance and it has to be checked or measured…

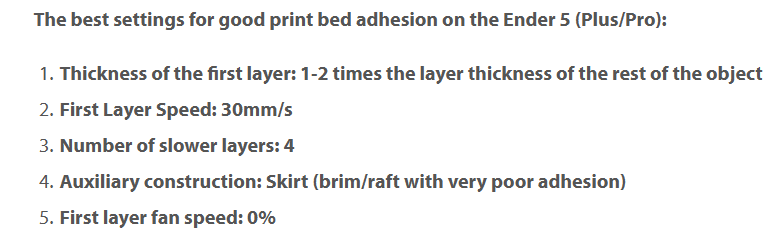

Some other suggestions I found:

Thanks for the suggestions. It is the first layer that is not working well. Even with a Brim it is still not stringy but lines. It’s like the higher up the print it goes, the better it gets.

Nice setup… ![]()

I’m having a similar issue with my V3 KE however I’m new to 3D printing. I’ve made (what I consider) many successful prints but I too have first layer sticking issues. If my first layer sticks (hit or miss) then the rest of job prints without issue. The print gets progressively better. It’s just the inconsistency of layer 1. I’ve auto leveled and adjusted my Z tolerance +/- to find the best adhesion. Just when I think I’ve found it by testing a few prints it just fails on the next one. As mentioned there’s no consistency.

I’m starting to narrow it down to either a flow issue in the code/controller, which is probably not even viable, or the possibility of the bed not heating evenly. There seem to be cool spots where the layer won’t stick consistently. By consistently I mean most of the 1st layer fails in nearly the same quadrant of the bed. I’ve no way of measuring the bed temperature outside of an average so it’s not definitive. I may be way off but, again, I’m new to this and don’t know what I should be looking for or expect. Forums only get you so far…

I’m wondering if you’re experiencing the same potential issue if the 5 pro has a heated bed?

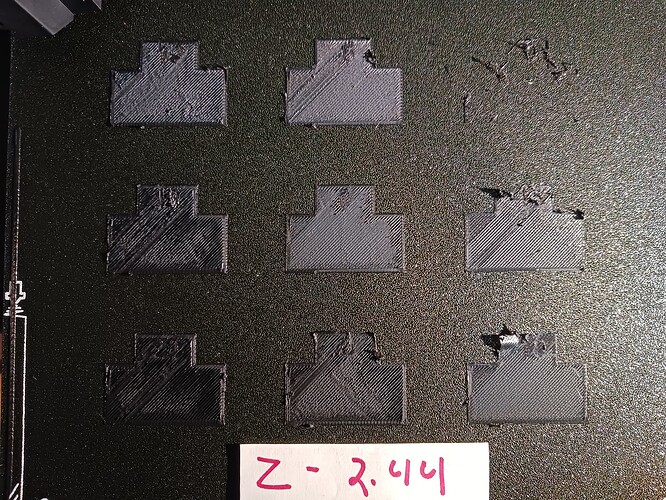

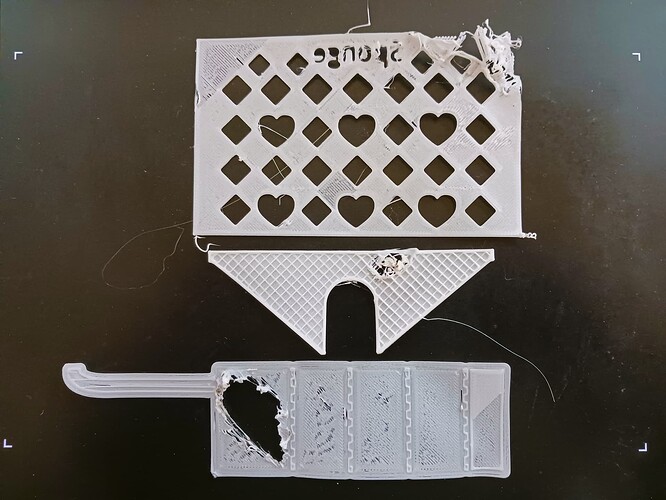

I just included these images to show the failure of the first layer at different (paused) stages and then a successful calibration print without issue.

Looking at your photos I would say that its possible under extrusion. If the printer is under-extruding then it wont be laying enough filament on the bed for the edges of each pass to interconnect. I would recommend running some calibrations to ensure that your esteps are set correctly.

Here is a how to for calibrating esteps on the Ender printers…

How To Calibrate the Extruder Steps (Ender-3 / Ender-5 / CR-10)

Thanks for the info. I will definitely check that out. I was doing some reading online because this is with the new direct drive extruded. I set it to what a reality says to see if at but ![]() The rink is inside Fond du Lac so travel isn’t too big an issue.

The rink is inside Fond du Lac so travel isn’t too big an issue.

Here is the latest print. You can see that it turned out pretty good except for the floor. H

You’re very welcome. The latest print looks good, I still see a few extrusion issues but hopefully the calibration will help you get everything fine tuned so that the filament flows nicely ![]()

This is what’s baffling me. The print looks good ( a few tweaks to polishing good) but the bottom layer is still crap.

Its hard to fully tell whats going on but it does look like you have uneven adhesion as one side of your model shows squishing whereas the other side seems to show gapping. I would double check your bed is level on all four corners and run the auto leveling again afterwards as it looks like there may be a slight slant to the bed. It will also give you a chance to check the nozzle height from the bed is correct.

I still suspect there is slight under extrusion or possibly over/under retraction. Usually on a direct drive system you would run a retraction length of between 0.35 and 0.8mm, at maximum 1.2mm. Anything higher than this tends to remove the filament from the hotzone causing extrusion issues.

I don’t have auto level on it. This is one of the early 5pro models. I have a CRTouch for it but couldn’t ever get that thing dialed in correctly. I want to eventually get a second z axis drive and CRTouch so I won’t have to mess with the bed leveling. I have a runout sensor too but I need to print a bracket for it. My next step will be the calibration.

You wont need the touch probe mounted to ensure the bed is level, ideally you want to ensure the bed is level and equal in all four corners so that you know the bed is flat. You can do this using the manual paper leveling method without the need for the probe. It will then just be a case of checking your esteps, doing a couple a calibration tests such as flow rate and you should be all good. The touch probes are handy but nothing beats good old fashioned manual bed leveling to get the bed as flat as possible ![]()

That’s what I w been doing, the paper method. I think it is the flow rate. I usually have to tweak the leveling knobs when the print starts. Probably causing some of my own problems but I do that to get it to adhere. The calibration and esteps will probably my fix my problems if at a minimum make them far fewer.

Never adjust the leveling knobs after you have leveled the bed. Adjusting the bed screws when starting a print is the worst thing you can do, you should always adjust the nozzle height using the z offset function on the printer. Adjusting the bed screws during a print explains why your bed is likely out of alignment.