Hi to all !

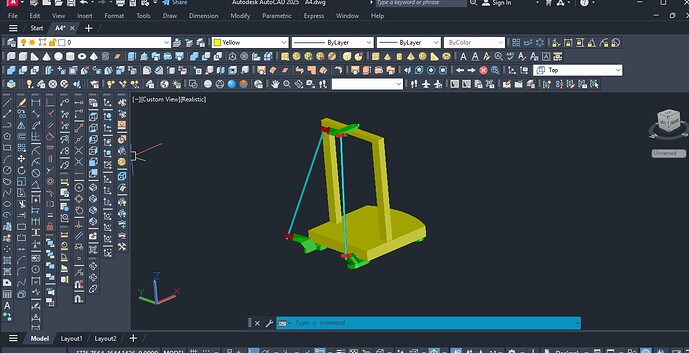

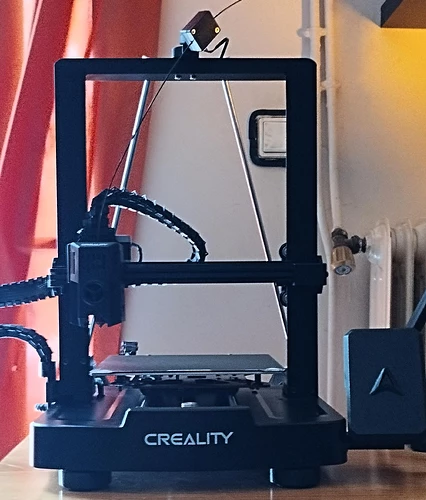

I designed this adjustable angle stabilizer…

I don’t know yet if it’s really useful but it will show .

A different way to do it than I did it, not sure about a central support, nicely done though. Have seen a fully 3D printed version including the trussing, wasn’t too keen on that version.

Thanks !

I haven’t tested it yet…will try to develop it as much as I can .

The next move will probably be to try on the linear bars it has, two parallel spring-connected ball bearings for setting controlled oscillation damping …

I’m looking at doing something like Wobblex on my Z axis, but there isn’t much room.

Until now, this is what I believe too…that is, that the KE needs and deserves a good mechanical solution for this issue… That is, something like a stabilized and at the same time shock absorber…

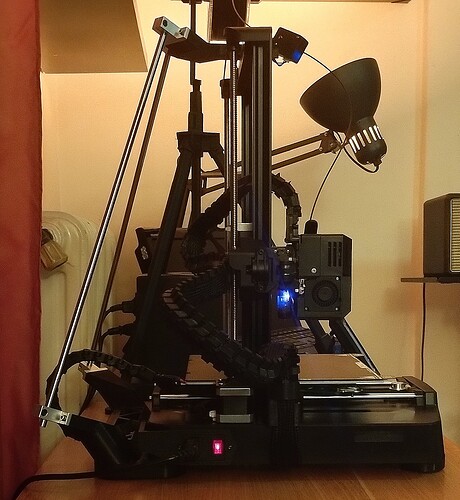

That’s impressive looking! I love the thinking outside the box and moving things to the back…I don’t like most of the ones that hook to the front corners and I have a side mount spool that changes the way the display mounts so I can’t do a front mount anymore either. With that said, considering the top crossbar is plastic does the upward angle of the 2 connectors push up and forward on that crossbar…was thinking that a forward “push” would be better than an upward/forward angle. But I’m just a layman and little technical abilities in that kind of design. Regards and look forward to more info about it going forward.

Thank you!

Τhe problem in the Ender V3 KE is the oscillation in the Y-axis but also the oscillation in the X-axis.

The specific stabilization system was designed to be effective on both axes with the help of computer simulations.

Also the system was designed to be installed without any modification of the printer,some tests also showed an improvement in accelerometer setup and operation.

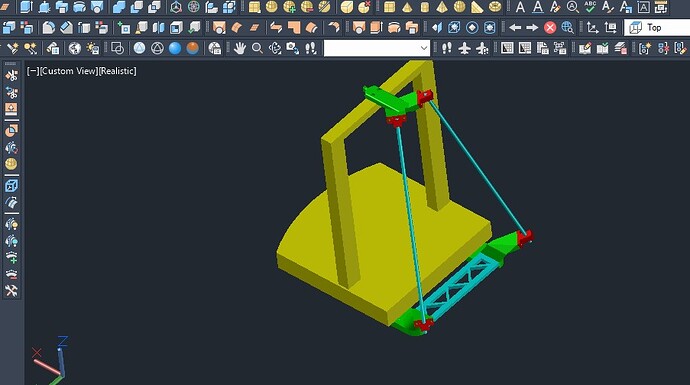

Now all the necessary tests have been done and it is in its final form.

The only thing that is pending is the creation of a user guide so that the model is available on the internet.

With the help of such a system and with two bearings nests of carbon fiber in its bed.. the printer is simply perfect !

Gotcha! Didn’t think about oscillation at all. I was thinking more about forward and backward on the gantry/crossbar due to the verticals and their simplistic mount. It’s a shame they don’t really design the sides of those verticals to allow for a smallish triangular plate to be affixed to the outside bottom area. It would avoid the need to reinvent the wheel to fix the inherent problem, and the taller and faster these get it’ll only get worse or limit the size & speed. But your solution is an attractive solution and still allow the filament on top - I like mine mounted on the side, but mainly because of the lack of overhead room. Anyway, will be following to see how the internet reacts and puts it thru the paces. Cheers.

This looks great, and I appreciate that it doesn’t require drilling/modifying anything to mount

@Ribas can you share the model somewhere? I’d like to print this for my KE as well!

So I can only share it among friends !

Ιt’s professional work, so it doesn’t get on the internet for free, that’s self-evident .

Well, if you want to be a friend, send me your email and I’ll send you the designs.

kaloneros@live.com

Thanks !!!

Thinking about your project again and was curious about things. 1) I’ve not made any prints over 4 or 5 inches tall yet and have not had issues that I think are related to the “weaker” design, so is there a point at which it becomes obvious and needs something like your design? 2) did you have any testing points for a before/after result(s) as you went along to see how the design helped, or didn’t? 3) do you think you have the kinks worked out or still tweaking the design? Regards.

Ohhh , what a question !!! ![]()

![]()

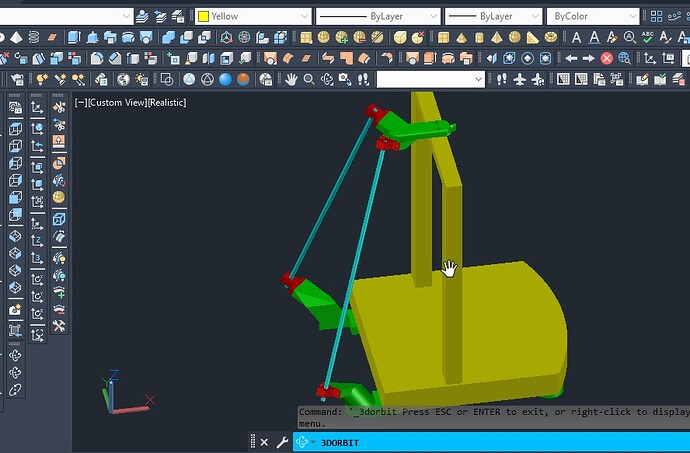

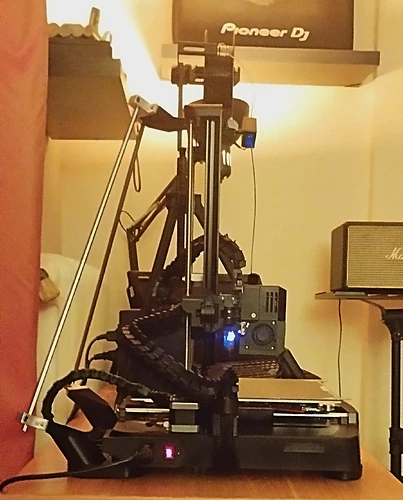

This particular project has been in development for eight months and has reached its final form with great success, and is designed and simulated in a professional workstation environment.

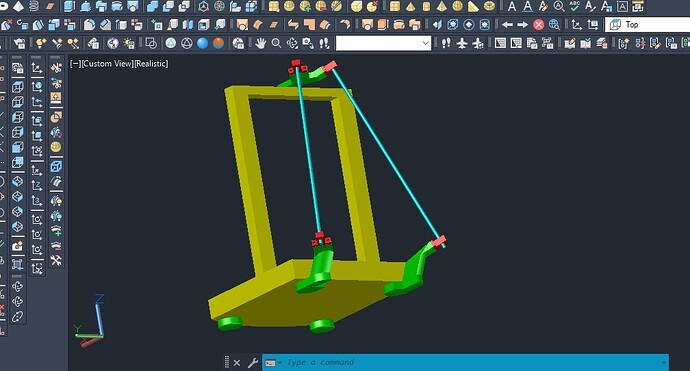

This is an adjustable stabilizer in the two axes (X, Y), and an angle adjuster (Z), it has the ability to adjust the angle as well as the ability to adjust the damping rate.

The depreciation rate is determined by the height of the rear bridge .(see photos)

Throughout this period until its final form, most of the tests were done with PET-G and CARBON fiber.

The results are amazing as the machine prints any PET-G and CARBON at high speeds like PLA! Much better response of the factory accelerometer was also noticed.

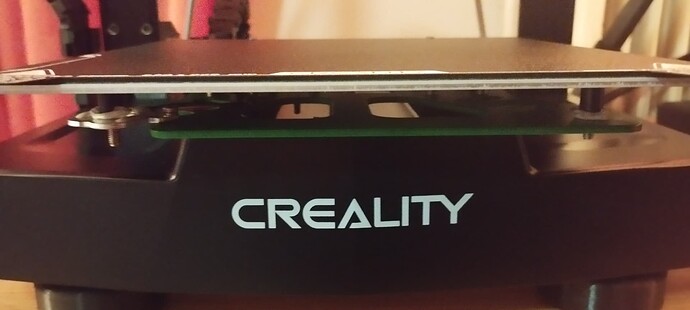

The only forced modification made to the machine to get the measurements right is to the bed where carbon bearing housings installed that were printed by the same machine , and slips of paper for vibrations.(see photos).All other mechanical and electronic parts have remained as they are from the factory.

So if you’re printing more PLA and less PET on your printer at moderate speeds, I think you can leave it as it is from the factory, you may sometimes see in the prints small imperfections in the external finish in conjunction with the proper lighting, nothing more, the machine is fine !!!

After that, there is the issue of stiffness ratio and how to deal with it in a 3D printer for better printing results, and it is a topic that concerns and will concern manufacturers in the future, especially in high-speed and low-cost products…let’s not forget that a large percentage of evaluation in a professional device or machine is determined more by its stability over time and not by speed .

Thanks I hope I helped you !

Best Regards Panagiotis.

some more photos…

This is an amazing project and sounds like you went thru painstaking and detailed processes to get it tweaked to near perfection. A couple other versions on the internet seemed like they might “help” but I felt like there was a lot of room for “wiggle” in their designs and executions. However, yours seems to refine the setup almost like a commercial design now!

Thanks for clarifying about PETG & CF…I do only use PLA because most of what I do is just fun stuff or art type work and nothing really structural or in need of PETG either. If I start printing taller things then I might have to do a project like yours to improve the machine but the point of diminishing returns may not be worth the time and trouble either…as I get older I am realizing that sometimes its just cheaper/easier to get a different machine than redesign/rebuild the wheel…however your fix is so cool that it might be interesting to do just for the fun of it. LOL

If I ultimately do an upgrade I might start with ordering the bearing housings for a 10mm rail set kit that I found online and get some tighter tolerance bearings…but I don’t think my stock setup is bad like others have found.

I don’t know if you had any desire to make/market your final “kit” but I’ll keep an eye on things in case you do! Thanks!!

I agree with everything !

I have the impression that the 10mm kit you are talking about is currently the best upgrade for the machine on the market ,I haven’t tried it, but from what it seems.

If at some point you try it on the machine, I would like you to tell me your impressions about the quality of the rolling of the rails.

Thank you!

Been a while since I looked in on your project…does everything still seem to be working smoothly? I didn’t bother with anything regarding bracing or 10mm rail kit as I am having decent enough success since I rarely fill the bed with large things in the x & y and almost never exceed 5" tall either and with the filament mounted on the side I don’t get enough movement to care…for now.

Hello !

I haven’t added anything new to the project , I think it’s finished..

I am generally satisfied with the whole machine , it is stable in the sense that it prints things over and over without any problems , everything looks good so far !

The truth is that I am quite curious about the 10mm rail kit and especially about how good the rolling quality is ?

I have a technique for screwing the bearings on to the bed that might help.

Ιf you use small washers on the bearing screws and then screw in the right bearing first by pulling the bed with your hand to the left and then screw the left bearing better by pulling the bed to the right with your hand , then I think it will be perfect !

It does look nice! I’ve been thinking of the 10mm upgrade but I have mine sitting on a short vertical style freezer and it takes some of the vibration out of the equation and since I don’t have a need for tall projects yet I am going to wait on doing that or even something as venturesome as yours either. I will likely jump to a xy core system like sovol 8 or troodon 2 setup. Maybe. But I love your solution!!!

Ender KE adjustable angle stabilizer is available for printing here ![]()

ENJOY and HAVE FUN !!!