Purchased k1 summer 23 . Limped along with extrusion issues not knowing any better till my original hotend broke. Creality sent me the upgrade at the time. The red sock version. I bought the upgraded extender . Worked fairly well till I tried to use the hardened steel nozzles I bought from Creality. Hard jams, extruder clicking. Removed and checked everything. Squishy chunk between the blue center tube and the nozzle. Tried the old brass, no dice.

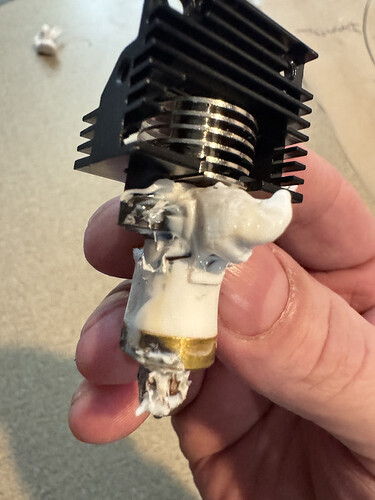

Bought the unicorn nozzle. Failed miserably in Creality print, prusca, and finally orca before it globbed a giant chunk of pla around the nozzle.

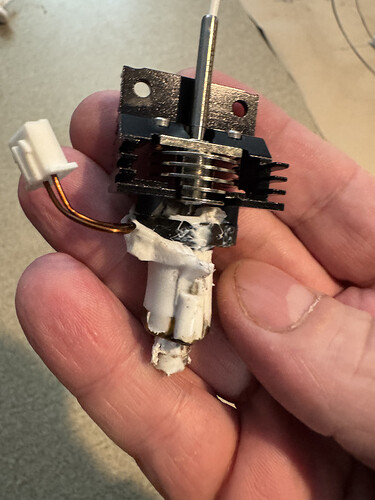

Ripped off the temp probe wire removing giant solid chunk of pla.

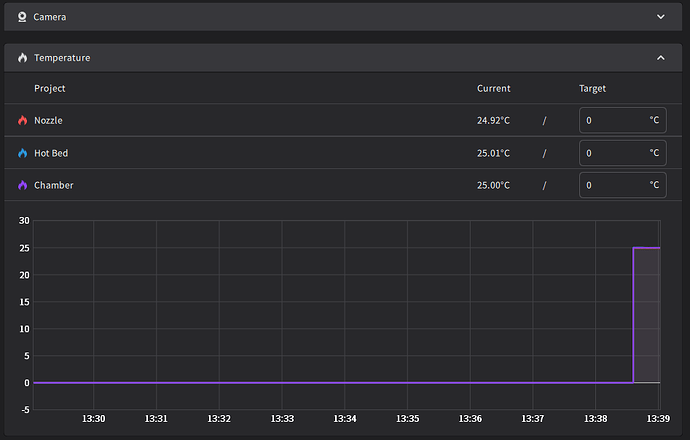

Completely dismantled and reinstalled old extruder. Reset machine, re rooted machine. Latest saw and all that.

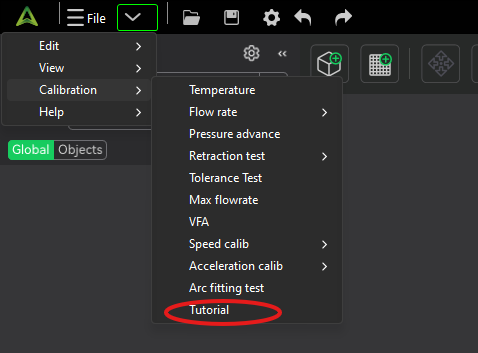

Never once have I successfully performed a flow calibration through this machine. Just reset and cuss during post process.

Now nothing will extrude, every nozzle clogs regardless of preheat. My unicorn is shwacked and I’m disappointed yet again wishing I’d of bought something else.

The entire internet seems to just rehash the same tired lines of base troubleshooting a clog. I need something a little more insightful.

No debris in the extruder. Thermal paste on the hotend shank. Fan works, intermediate tube intact, no leaking.

Zlytech pla , tried 3 different rolls including one brand new out of the plastic.