Hey all, this is my first post here so please bear with me if I miss anything, and feel free to let me know what I might need to include.

Recently I got my first printer, the Ender 3 v3 KE, and for the most part it has all been good.

I’m having two issues though, the first being poor first layers with the automatic calibrations, and the second is what seems to be overextrusion from what I have been able to find while looking things up. I’m looking for any advice on what could be the cause of these issues, and/or anything I might try in order to resolve these issues.

I am using Orca slicer and have used all of its built in calibration tools to try and calibrate for my filament. Initially I had these issues on only some prints using Hatchbox Black PLA, and have been having all the same issues using Elegoo Black Rapid PLA+ as well, but have only run one print with it so far.

Images/videos are prints done with the Elegoo filament.

First Layer Issue:

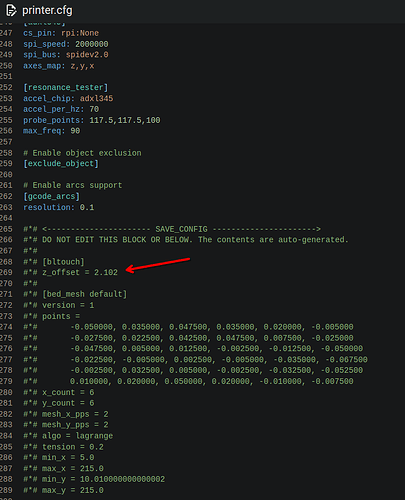

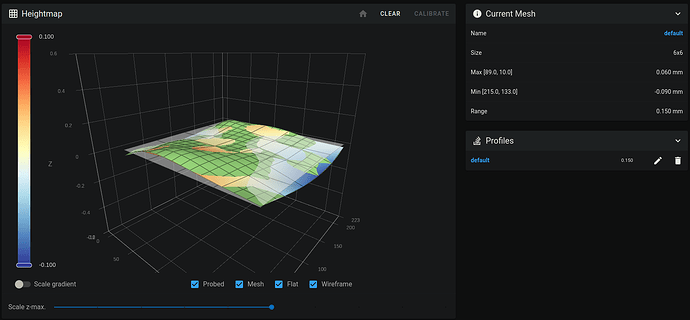

When printing the Benchy that comes with the printer everything is fine, but with the automatic bed leveling and z-offset done by the printer, as soon as I try one of my own prints, unless I modify the z-offset the first layers are very poor, causing the print to not adhere and thus fail.

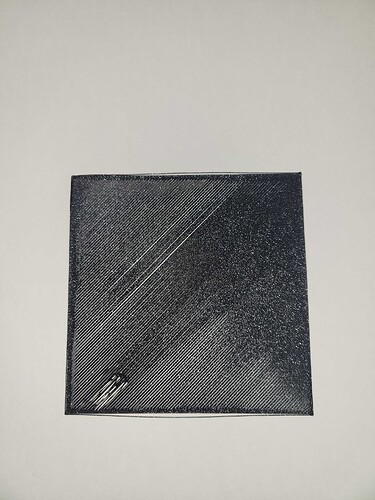

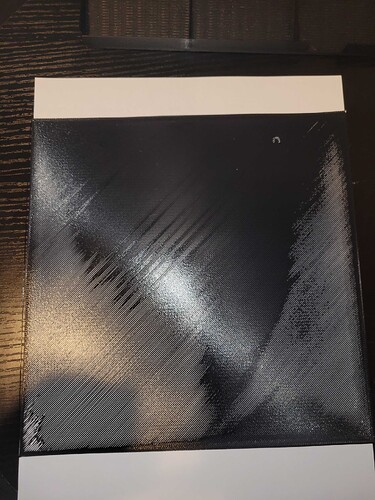

I have done a few test prints of single layers (100mm x 100mm) and with the default calibrations and what I felt was happening was that the nozzle was too far from the bed, and the result is the image below. Other than the section that is solid in the top right corner leading down to the bottom right, everything that is lighter are individual strings and not actually connected in a cohesive layer.

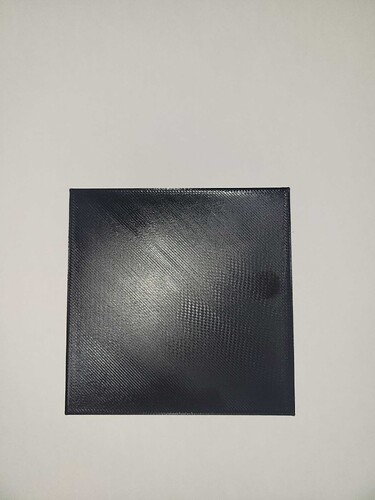

This seemed to be confirmed when I set the z-offset to -0.1 (did the change directly on the printer, then removed it from the printer and made the change in Orca instead and had the same results) I got the below first later and this has been successful on all other prints I have run with this setting.

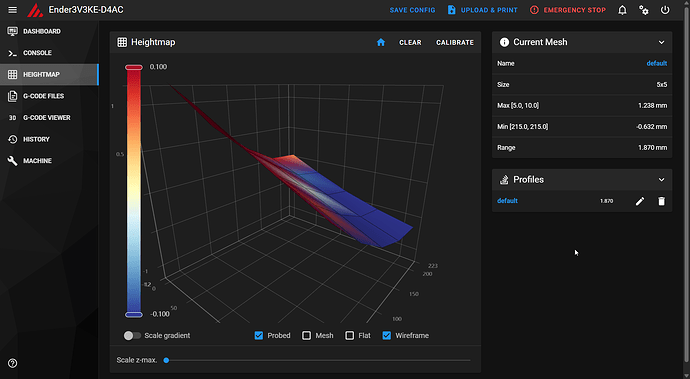

I then tried to run a full print bed first layer (220mm x 220mm) with the negative z-offset and got barely halfway through before it was too poor to continue. I do not have an image of this one, but near the front of the bed was especially bad with a lot of holes especially around the corners of the bed, and the print failed before it got to the back of the bed so I am unsure if the back of the bed has the same issue.

Generally I am happy to leave this setting and just make sure I slice my prints in the middle of the build plate, however, my question is that if the printer should be doing this all automatically, why would I have to go in and adjust again after? I confirmed that the bar holding the hotend is level when z is homed. Should I be trying to manually level the bed even though the machine does it manually?

Is there something I am missing that I should check/adjust on the printer to make my first layers better?

Overextrusion Issue:

For this issue I am not sure if it is truly overextrusion, but I don’t know enough to be sure. When trying to diagnose the issue myself I found this Reddit thread where OP was having the same issue I was and based on the tread this is overextrusion. Initially using the Hatchbox PLA I used the Max Flow rate calibration from Orca slicer and came up to 18 mm ³/s for the max volumetric flow, but this was the value I already had in the filament settings.

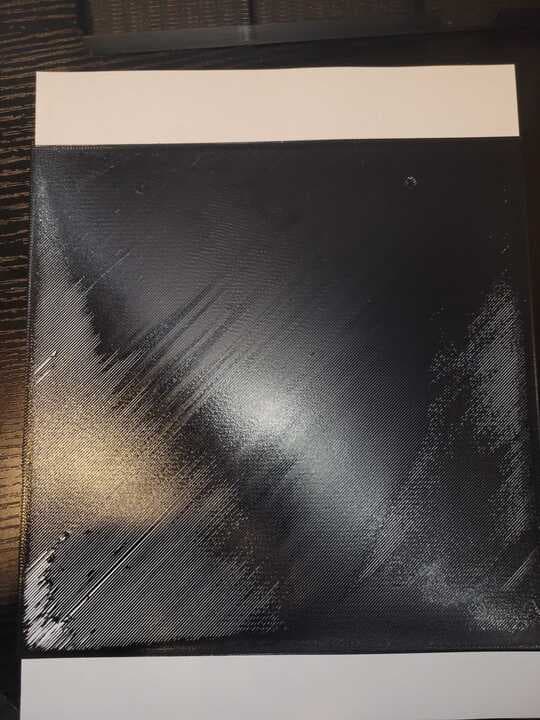

Below is the first print I have run using the Elegoo PLA after running the Orca calibrations as well, and I still have the same noise.

The Max volumetric flow for this print was also 18 as I wasn’t 100% sure with the results of the calibration test.

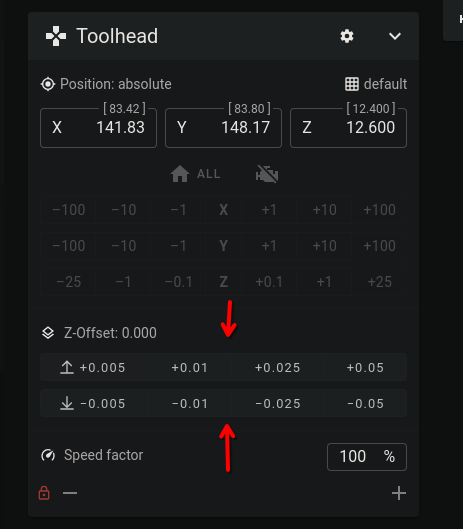

I am unsure if this is actually overextrusion though given the first issue with manually changing the z-offset. It sounds like the nozzle is scraping the print, and so could that be caused by the negative z-offset? When this issue was happening I went and manually raised the z-offset by 0.1 mm mid-print and it sounded better but did not completely fix the issue.

Given that it did not compeltely fix the issue but did make it better, could it be a combination of overextrusion and too negative of a z-offset

One thing I have yet to do that I did come across is to calculate the e-steps, but I am apprehensive to do this as I am not sure if this would solve the issue since I am unsure if this is actually overextrusion.

Would anyone have any other advice/knowledge that may lead me deeper into fixing these issues? Any help at all is greatly appreciated, thanks in advance!

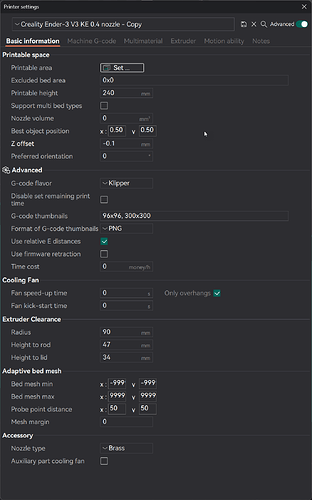

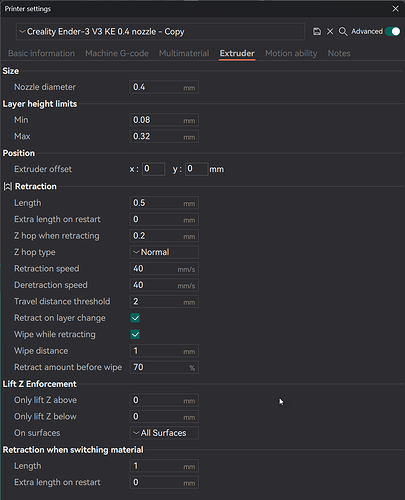

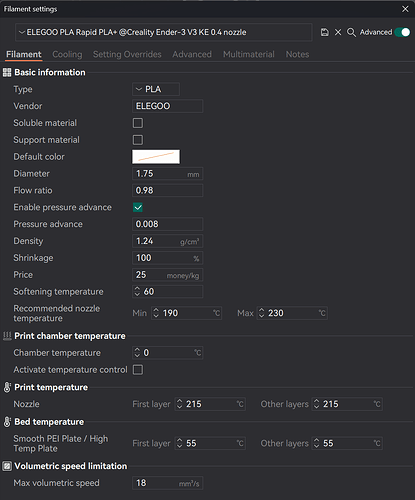

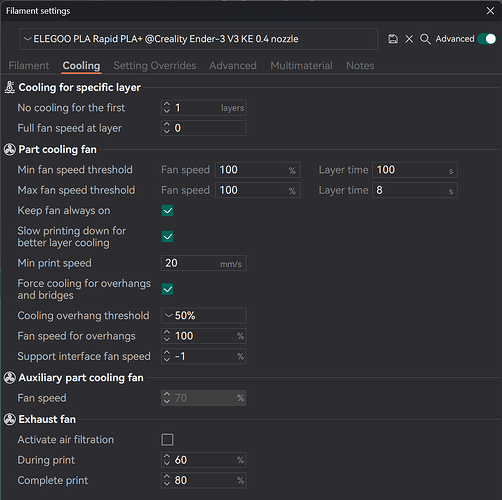

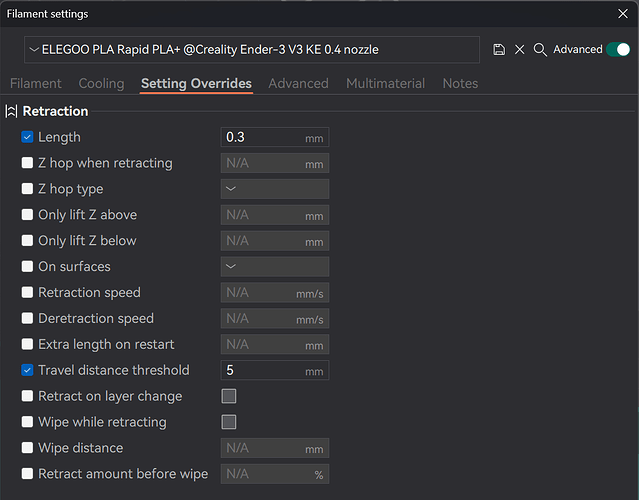

Below are screenshots of my various Orca settings of both the printer and filament for reference if they are helpful. If any other settings may help feel free to let me know.