Hi All,

I try to use new material. I purchased 3dJake.com ecoPLA 1.75 for me Elder3 V3 KE as for try calibrate new material. The technical specification said temp. 195-215C and density 1.24g/cm3. The rest of them need to determined by the calibration where I running to troubles.

I sensing the calibration menu point in Creality Print v4.3.8.6678 using the Material and the Parameter config which is also used by slice button. So I made few initial setting here.

New material created (funny you are not allowed change Brand name) and I reduced

- Max volumetric speed: 15.00 mm3/s

- Printing temp: 210C

- Initial Printing temp: 200C

- Final Printing temp: 195C

And also created new parameter config with slower speed settings (cloned from normal profile) - Print speed: 200mm/s and all other below changed by the SW automatically

- Printing temperatures matching the material data above.

- Build plate Adhesion Type: brim I made this due I had problem with the Hyper-PLA material also when higher levels (the print head knock the material and broken down the entire test model).

I am running with print below with prior calibration the ensure about Z plate level.

-

When I tried with the Temperature calibration between 220-190C with 5C steps printed out without any problem.

-

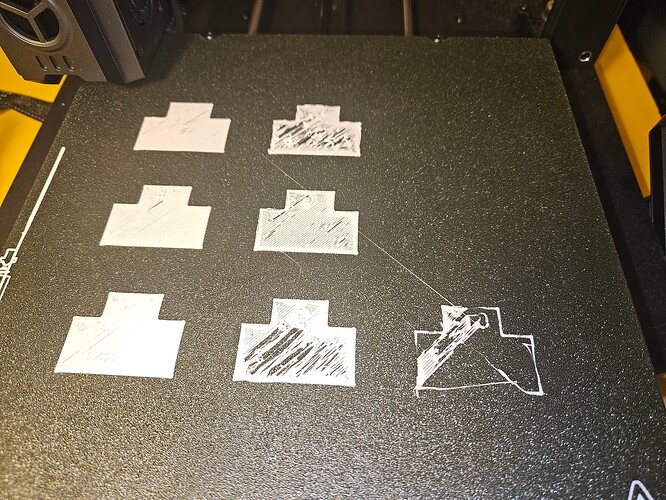

OK go to the next step. The Flow rate Pass-1 test I was unable print out. Here is the picture I stopped when reach the -10 plate due totally broken frame. As you can see all those test unable print correctly the 1st layer. Meanwhile initial layer print speed 100mm/s and initial layer travel speed 37.5mm/s (if they really uses my ecoPLA settings selected above for the calibration)

-

I also tried the Max flowrate calibration that is mostly printed out just the 20mm3/sec have not smooth wall so I used 15mm3/sec correctly as max flow rate

-

Pressure advance test not possible due with autobrim settings the small circle brim around corners not enough stable to my complete printing move away from the pad

Anybody could have good practice how to board new slower materials in this relative high speed printer? Any better approach or idea?