Hi,

After some weeks of testing etc with my K2 plus CFS I am trying to print a cube.

See Spin Cube (Print in Place) by liminil - Thingiverse

When reading some documentation and trial and error sessions still nothing works. It is not spinning.

The answer to my project seems to be a “PIP construction” or enabling “assembling” .

But I can not find these options within Creality Print v6.

Can anybody help me, or give any hints.

Thx on forehand!

Its print in place so for me as long as the print wall order is correct it should just work. For my mind it should outside/inside not inside/outside, the latter makes a bigger part. Turn off all brims/rafts/supports, it should just work. Can you show what is going wrong in a picture?

Hi Bonfireman,

Thx for your prompt replay. I had the flu, But recovered well.

I have tried several options, but nothing changed…

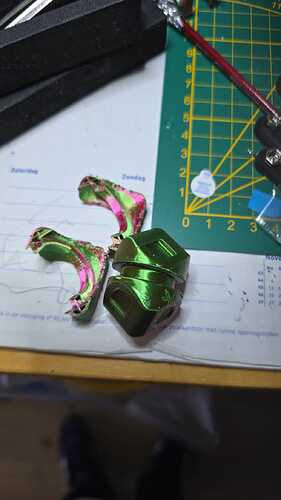

See also attached the pictures.

I couldn’t get that PIP to work either, currently with ABS loaded, might try PLA+ in a bit. Printed loads of dragons and lizards PIP models, no problems. I’ll give the cube another go on a different printer.

Hello Bonfireman,

Interesting, I actually tried the exact same “PIP” cube myself a week ago using PLA dual colour silk as that is what the original looked like it was printed with … didn’t work for me either.

I had a cube, but that is all it was.

Cheers.

ABS I just got a cube. PLA inside/outside wall order I got a cube. PLA outside/inside (as I surmised) spinny toy, little tight but moves. May have been better with an aux fan at 100% in addition to the other cooling fans, except I don’t have any of those on the Ender5plus that I printed it on.

I remind this model which I tested on my Qidi printer (I still have aside the K2) and id tid not work out of the box.

The reason is that even side/auxiliary fans cannot cool the internal overhangs because of the model is blocking the airflow with the bigger external part.

I had luck by setting X-Y-contour compensation to -0.1 mm (On Qidi I used -0.15) and using my standard 0.2mm profile with Elegoo RAPID PLA easily!

One other comment on the K2: 90% of my PLA & PETG need a corrected filament profile (see my method here) if you do not want to use full calibration on every print.

The standard ‘General XXX profiles’ do generate no good outcome because on 90% they produce over-extrusion or bad PA values.

Tried it on my Qidi Xplus3, 0.12 layers…another cube, not toy. This cube is quite a fun challenge.

Hi all,

I am still busy with my subject. And still searching thru the internet.

And finaly o yes, I find the answer.

(My initial post: How print pip or assembled projects with creality print v6).

Actual situation: please open thingivers 6246656

please check “https://www.thingiverse.com/thing:6246656/comments”

Download the stl file, and open the file in creality print 6.x

Then execute Hollowing → 1.0 mm

And I changed:

“X-Y contour conpensation” to -0.2mm

And printed again → the cube was (little bit of force) turning around. It works!

Thank you all, for supporting me!

Now I will try better filament. Now it has tangible layers.

In case anyone has some advise (currently this object I printed with PLA

grz everyone

It is a tricky print, of 6 that I made off various printers I could only get one to work, all with the “same” settings supposedly.