As I am printing many different filament types I had some problems that CMS was not strong enough to pull back the filament. This happened mainly to special filaments like matte PLA, Wood, Stone, or Multicolor-Silk and of course some GF or CF enforced filaments.

Most of them generate additional friction in the tubes because they are either not so flexible or have a rough surface.

A college used a mot on his K1C with AMS where he changed the tubes to Capricorn tubes to reduce the same problems I had and I have seen a video to upgrade the CFS with such tubes.

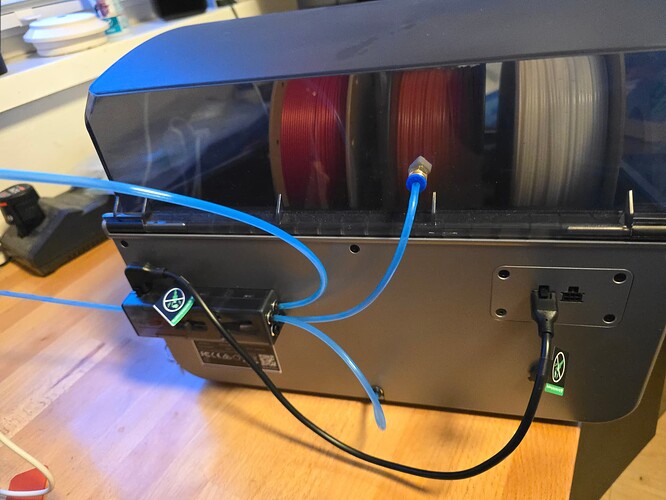

I ordered a Bambu Lab AMS Kit from 3DJake and received it a view days ago.

I had to exchange the tube which is going to extruder because I hat to cut it already some times when it starts to wear out at the end and does not hold in extruder anymore when CFS pushes in new filament. And because Creality did not manage to send me replacent tubes I bought the above ones.

I also have to mention that I did some other changes to my CMS a month ago:

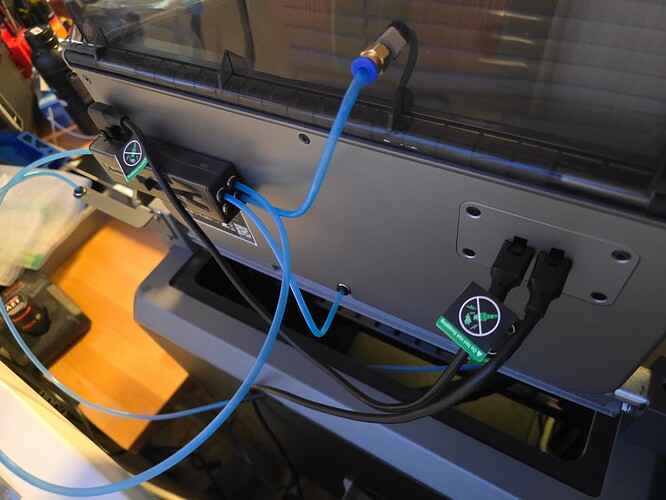

- I mounted the filament buffer on the back of the CFS so I could more easily move the CMS from the top of the K2 aside.

- I bored a hole behind slot #2 and inserted there a tube socket to connect this with a short tube to one of the free entries in the filament buffer.

- I connected to tube from the external spool holder to another free entry to the filament buffer!

This way I could use the CMS slot #2 as a sort of ‘external spool holder’ for filaments which I wanted to keep in dry area when printing but which I could not print with CFS.

I also could use external spool holder without removing and tubes from the K2.

I only have to pull back manually all filament from spool holder or CFS ‘external’ slot before I can use CFS again.

Now with the new tubes I exchanged all these tubes connecting the CFS, the K2 and the external spool holder. Not so far the internal tubes on CFS.

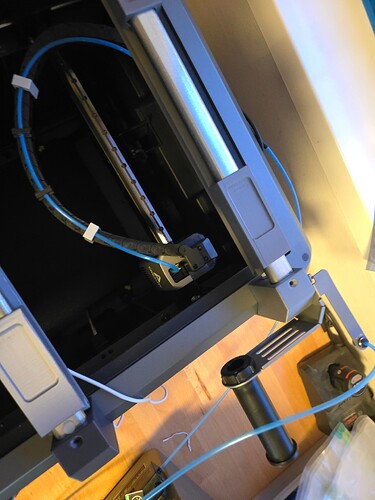

I also made a change to connect the extruder tube directly to the filament buffer removing this connector where you can connect either the external spool holder or the filament buffer.

Now I have much less friction on the filament and I can print many more filament types with the CFS.

I have even one empty input slot on filament buffer for a 2nd CFS if I will buy one on next black Friday

!

p.s.: Had no CFS problem since then and will exchange the internal CFS tubes like seen in above video also when I need to open it but this did not happen so far!

p.p.s: For all those who look too careful onto the pictures:

- I printed myself in PETG also some K2 Bowden Clips and added two of them on the tube to the extruder.

- I also use a self printed CFS raiser which hold the glass 2cm above (for all PLA/PETG/TPU prints) and also is a holder for spare print plates. I did this before I fould a fully printable solution here

- I mounted the spool holder on my CFS raiser because I have no space at the original height

3 Likes

@frankjoke

This is an interesting observation as I also had come to a similar conclusion.

I have had my machine for six weeks and had both the extrusion error and cant return to the CFS.

My belief is that there are a few fundamentals here that Creality need to address:-

-

The actuation of CFS motors which are not synchronised properly with the K2. This can cause the filament to kink within the PTFE tubing as the extruder pushes and the CFS motors wake up to pull.

-

The motors are not producing enough power to load / unload the filament. Massive difference between CFS and Bambu AMS. (same weights etc). When pulling back there is a significant difference in the comparisons. Watch when loading unloading and see it stutter.

-

The inner diameter of the PTFE tube is 1.95mm. I have measured filaments when they have been thru the CFS motors and extruder (unload) and this has a big impact on how easily the filament passes thru. The diameter of this altered filament varies between 1.8mm and 1.85mm. (Bambu Labs std PTFE is 2.5mm internally.) I believe that when you add this small difference to the tight radii of the PTFE tube it increases the resistance of the movement. Add to that the weak motors and jamming can occur in the machines interface. Then add a possible kink somewhere along the PTFE from a jam and it again adds to the frustration.

-

When an error does occur the Creality system appears to force you to “retry”. When you have cleared the issue and you hit OK it should clear the error in the machines memory. I do not believe it does and its only when you do a factory reset or reboot it eradicates the stop machine error.

-

Lastly when I have had a “cannot return to CFS” error I have taken the PTFE tube off the five ways diverter and blown compressed air from a can along the tubes. This appears to help in resolving the possible build up of dust on the gears at the motor end.

Since the last time I have changed all my PTFE tubes to Bambu supplied and have not had any issues. fingers crossed.

Hope this helps others in resolving the above problems

1 Like

Yes, I have the K2 Combo also for ~7 weeks and similar experiences.

The Capricorn tubes have 3mm inner diameter and are sold to even improve AMS operation…

Due to reduced friction the extruder motor (and the CFS one) saves energy and will not wear out that much. If I push in filament from external holder it feels like only half the power needed than with original tubes.

With the five ways diverter you mean the filament buffer (that’s how it was named on the K2 install instructions and support site)?

I had twice filament stuck in filament buffer that I could not remove it from either side and had to dismantle the filament buffer to cut it internally to get it out.

Anyhow, it took 10 minutes and a view $ to exchange the tubes which I saved already in time with the hassle-free operation since then.

@frankjoke

Hi

No, I am referring to the base of CFS where all 4 filaments meet and exit as one enroute to the buffer.

My apologies if named incorrectly.

@frankjoke this is a very interesting post! thanks for sharing. I am going to make a set-up like yours, as I face similar issues! good to know! Thanks!

So now I’m even more confused. I’m having the same problem where the boden tube pops out of the back of the CFS, then it continues pushing filament for a few seconds. Now that I’m looking at your photos, I notice another boden tube coming out of (or going into) the lid of the CFS. I don’t have that on mine. Is that another mod, or am I missing somethin in this thread?

Hi, just wondering how this mod is performing for you? i see the tubing is 3mm ID. Thought 2.5 was optimal?

I had to change some short tubes back to stronger (2.5mm) tubes because they do not like corners with harder filaments, they wear out too fast then.

For the long tubes with no short corners they are doing well.

Thats good to hear thanks, in the end i decided on 2.5mm OD and got some Sovol stuff of Amazon which ill do the mod with. going to run 2 feeds directly off a filament dryer directly to the buffer like you did with your single one.

That is a much better layout than the default…

Thanks

Chris

Other than my CFS still randomly chewing up filaments, it’s working better with the new layout…

Had to recalibrate all my custom profiles due to less friction, flow decreased significantly, and my space pi dual via buffer is down to .89% -.91% flow for branded CR filaments against CR’s profiles.

Now if I can just get the CFS to be a bit more reliable, stop randomly chewing filaments or not rewinding based on the alignment of the stars (or other yet unknown factors)

I’ll be happy with my setup.