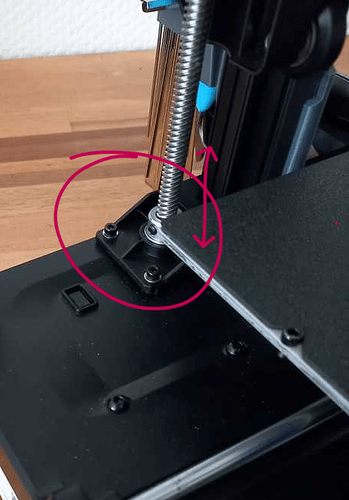

I am trying to identify the cause of some z-axis wobble on my new KE printer. When I checked the screws on the gantry and extruder arm I noticed that the non-motorized lead screw (see image) is not secure in the base.

The two screws on the coupling are tight, but the lead screw still lifts up and down from the bearing housing when that side of the x-axis extruder arm is moved independently from the lead screw connected to the stepper motor on the other side. It shifts up and down ~5-10mm. I have also ensured that the gantry screws on the underside of the base are tight, as well.

Is this intentional, or am I missing something that secures the lead screw to the bearing housing in the printer base? Is the weight of the x-axis assembly enough to stop the lead screw from jumping during quick movements when printing, i.e. travel moves and z-hops?

Both my KE and SE exhibit that, I’ve not worried about the high speed jerk affecting the Z axis as that axis barely moves per layer. Read comments about it, but no complaints, not seen any “fixes”, only seen “get your gantry parallel” so your comment:-Is the weight of the x-axis assembly enough to stop the lead screw from jumping during quick movements when printing, i.e. travel moves and z-hops? < it would appear so.

Thanks for taking the time to share your experience. I only noticed the movement after I installed my own gantry support. I’ll update this thread in the future if I have anything else to share.

For anyone in the future who is concerned about this, I found a printable part located here: Printables

It is an additional bracket that screws overtop of the lead screw collar and into the base. I haven’t used it myself yet, but figured it was worth sharing.

1 Like

I’ll give it a bash can’t do any harm. Printed a couple off in PETG, will fit in the morning when I have some longer black screws, which I have on my desk but not in my shed.

There isn’t enough clearance between that cover and the screw collar, probably be safer with an extra 1.5mm clearance, at the moment the grub screws rub. In the bin they go.

Slacken off the top coupling and push the rod down and push the top coupling up and tighten it back up, relevel the gantry and sorted

1 Like

I have an SE purchased in February and just now started to experience print squashing because of this. Lube, loosening and tightening X axis pole screws, and many iterations of gantry leveling haven’t helped because the pole just…pops up and down. Thanks for the part link: that’s exactly what I’ve been looking for since that pole doesn’t have a screw or casing holding it down.

FYI installing that part, re-aligning gantry, and then re-leveling fixed my issue. I didn’t even have to play with Z-offset.

I did this about a week ago and is working like a charm